Ultrasonic probe and method for fabricating the probe

A manufacturing method and ultrasonic technology, applied in ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, infrasonic diagnosis, etc., can solve problems such as cracking of piezoelectric materials under processing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

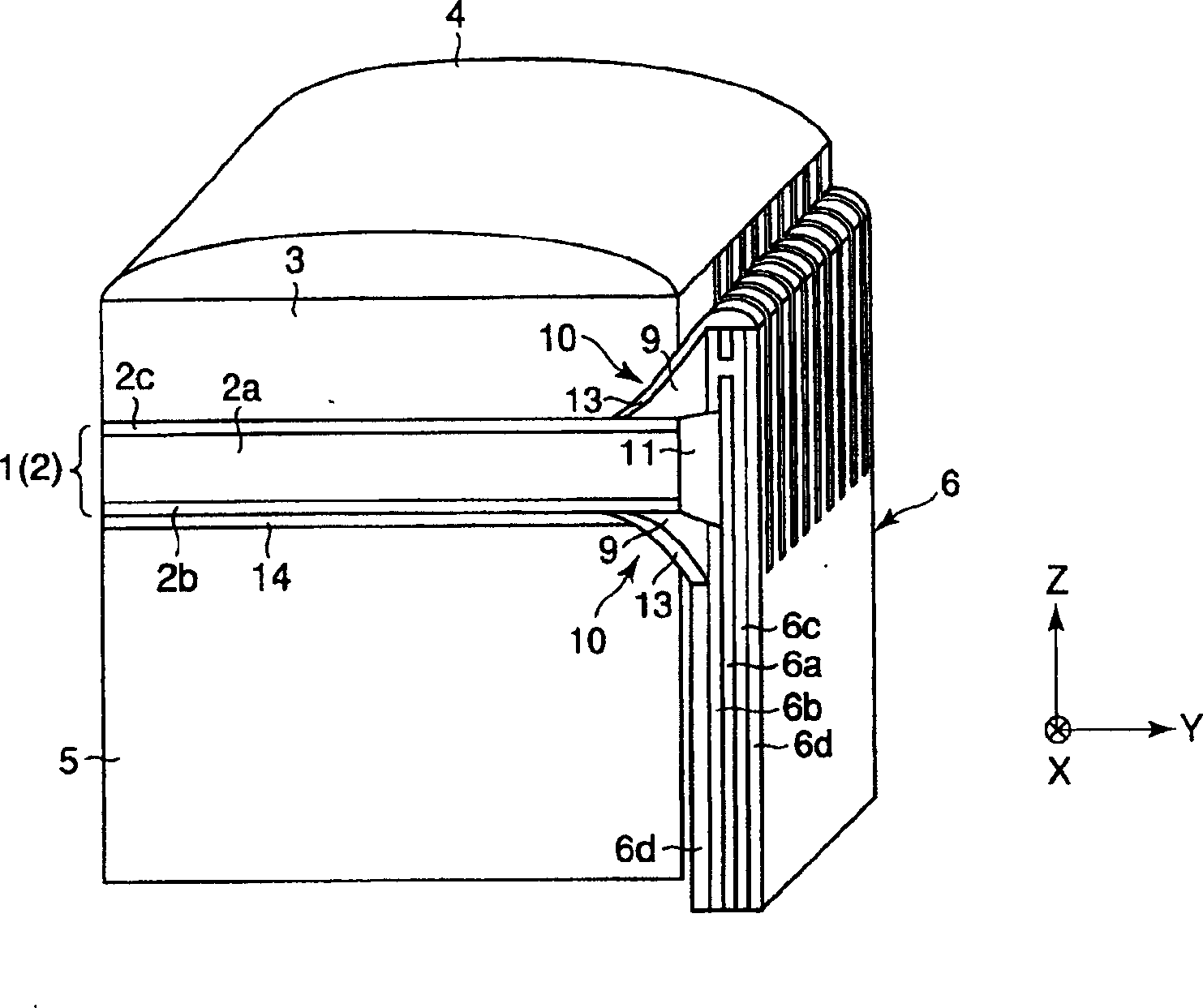

[0033] Refer to the following Figure 1 to Figure 8 A first aspect of the present invention will be described. figure 1 It is a perspective view showing the structure of the ultrasonic probe as the first embodiment of the present invention. figure 2 It is a sectional view showing the structure of the ultrasonic probe in the same embodiment as above. image 3 for display from figure 2 A cross-sectional view obtained by cutting the structure of the ultrasonic probe in the same embodiment as above along line A-A. Figure 4 for display from figure 2 A cross-sectional view obtained by cutting along line B-B.

[0034] figure 1 with figure 2 The ultrasonic probe shown in has a piezoelectric vibrator 1 . The piezoelectric vibrator 1 is made in the shape of a cuboid, and its three edges are perpendicular to each other, and correspond to the three directions of x, y, and z respectively.

[0035] Such as image 3 As shown, the piezoelectric vibrator 1 is composed of a plur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com