Equipment for conveying rod-shaped object in tobacco product

A technology for tobacco products and rods, applied in tobacco, conveyor, food science and other directions, can solve the problems of long failure time, high labor intensity of workers, affecting the efficiency of equipment use, etc., to reduce the time to deal with failure, reduce Workers' labor intensity and the effect of improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, describe in detail as follows:

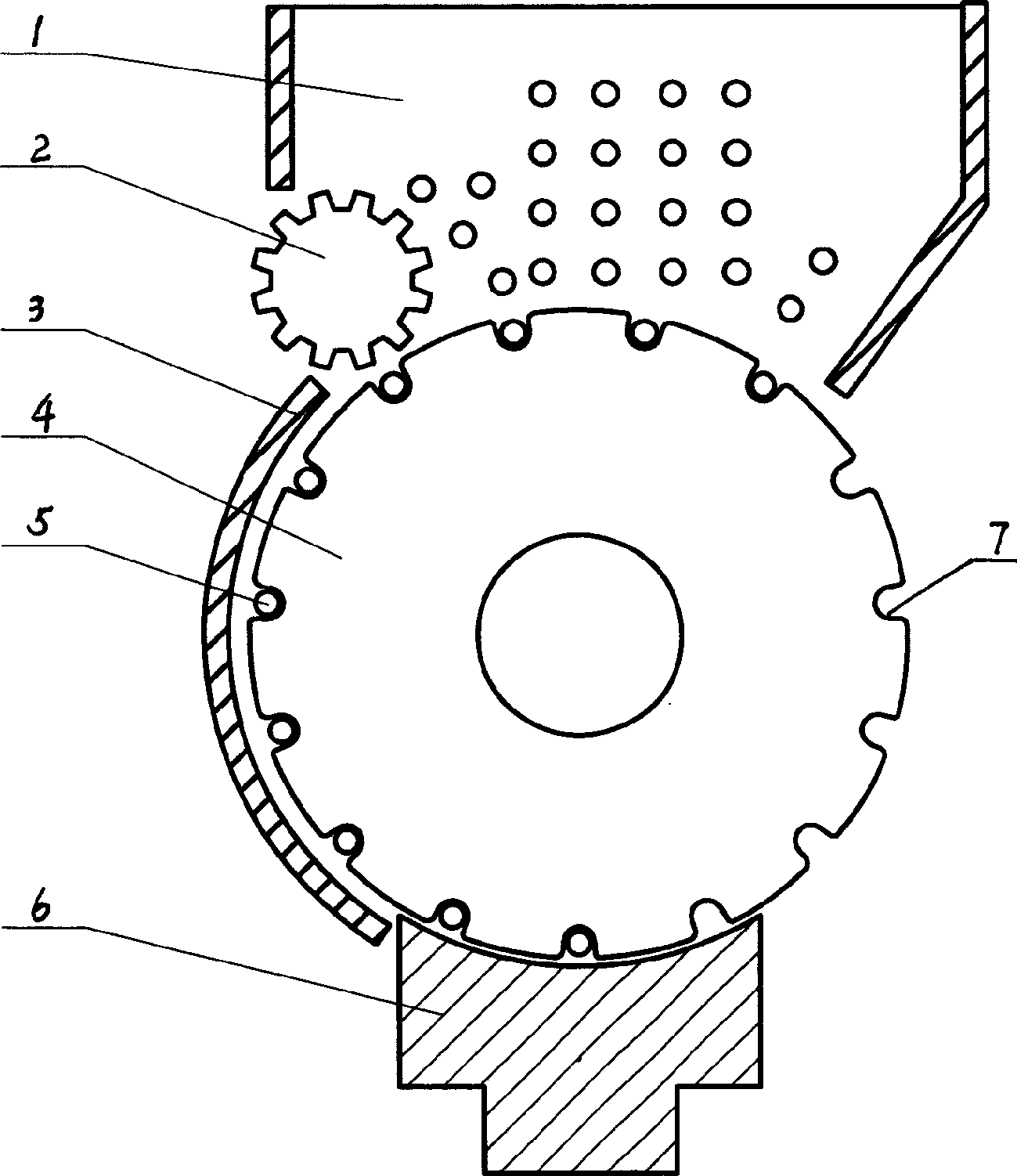

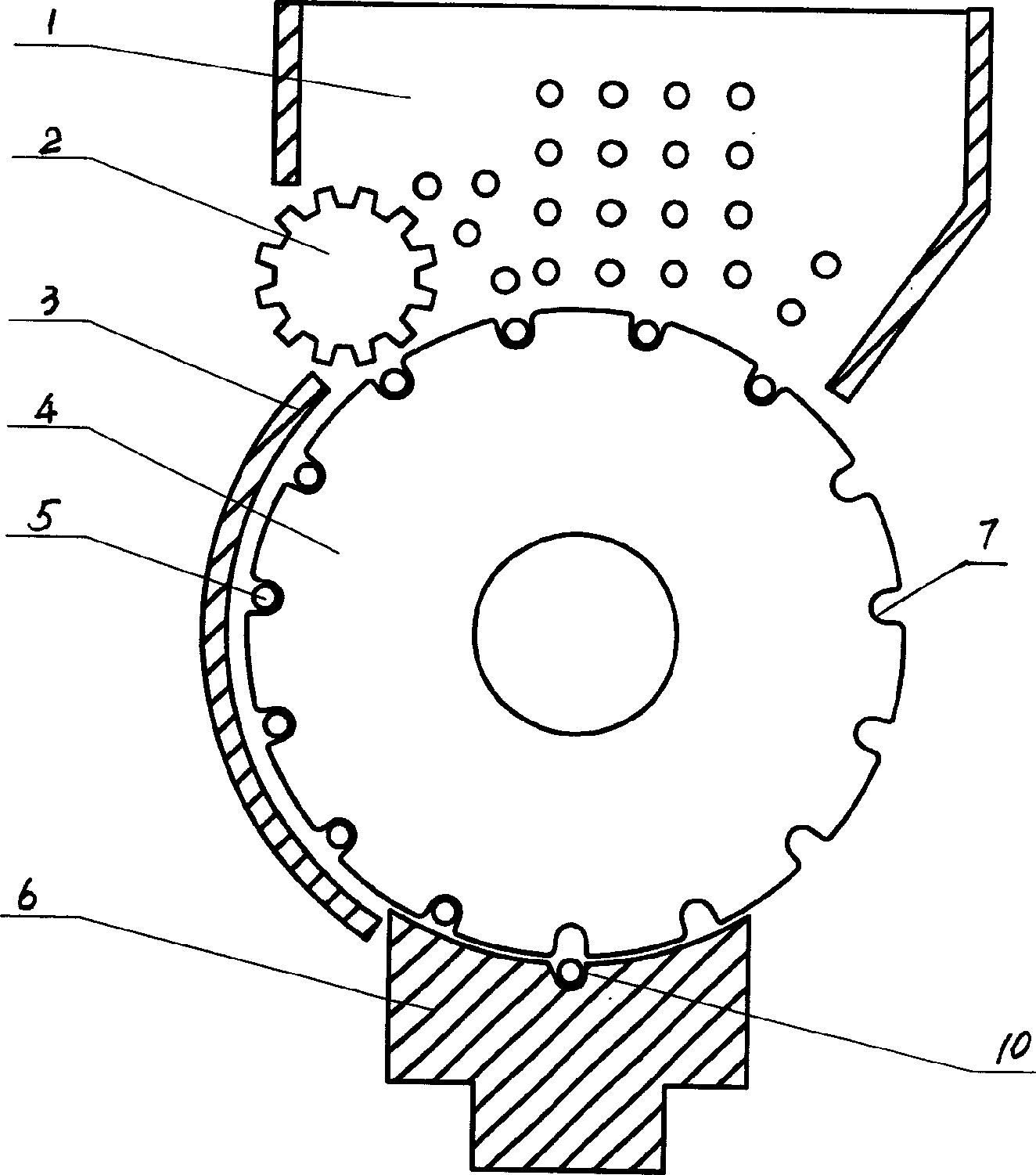

[0037] exist figure 2 Among them, the vertically falling part of the working mechanism is the material box 1, the drum 4 and the sealing block 6 from top to bottom. There is a pick roller 2 between the drum 4 and the material box 1. The guard plate 3 has several axial troughs 7 on the surface of the drum 4 , and the center of the sealing block 6 has a firing trough 10 .

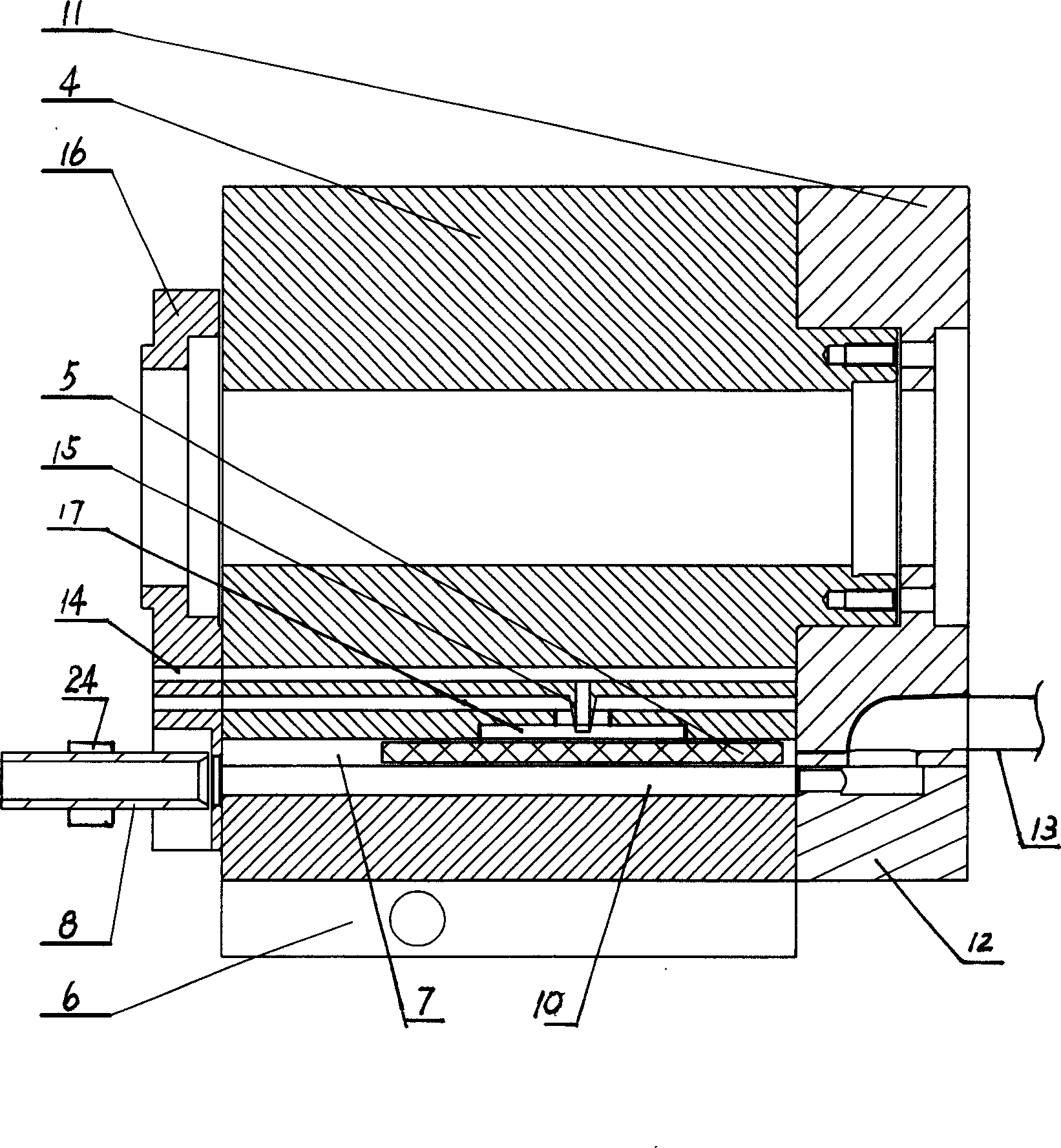

[0038] exist image 3 Among them, the gas distribution wheel 11 is fixed on one end of the drum 4, and several air holes are evenly distributed around the gas distribution wheel 11, and each air hole corresponds to the trough 7, and the gas distribution block 12 is fixed on the frame, located on the gas distribution wheel Below 11, at one end of the sealing block 6, there is an air distribution groove in the center of the upper surface of the gas distribution block 12, and one end of the gas distribution groove communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com