Double-X type flexible steel damper

A mild steel damper and steel plate technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of low initial stiffness and achieve high initial stiffness, good plastic energy dissipation performance, and energy dissipation good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

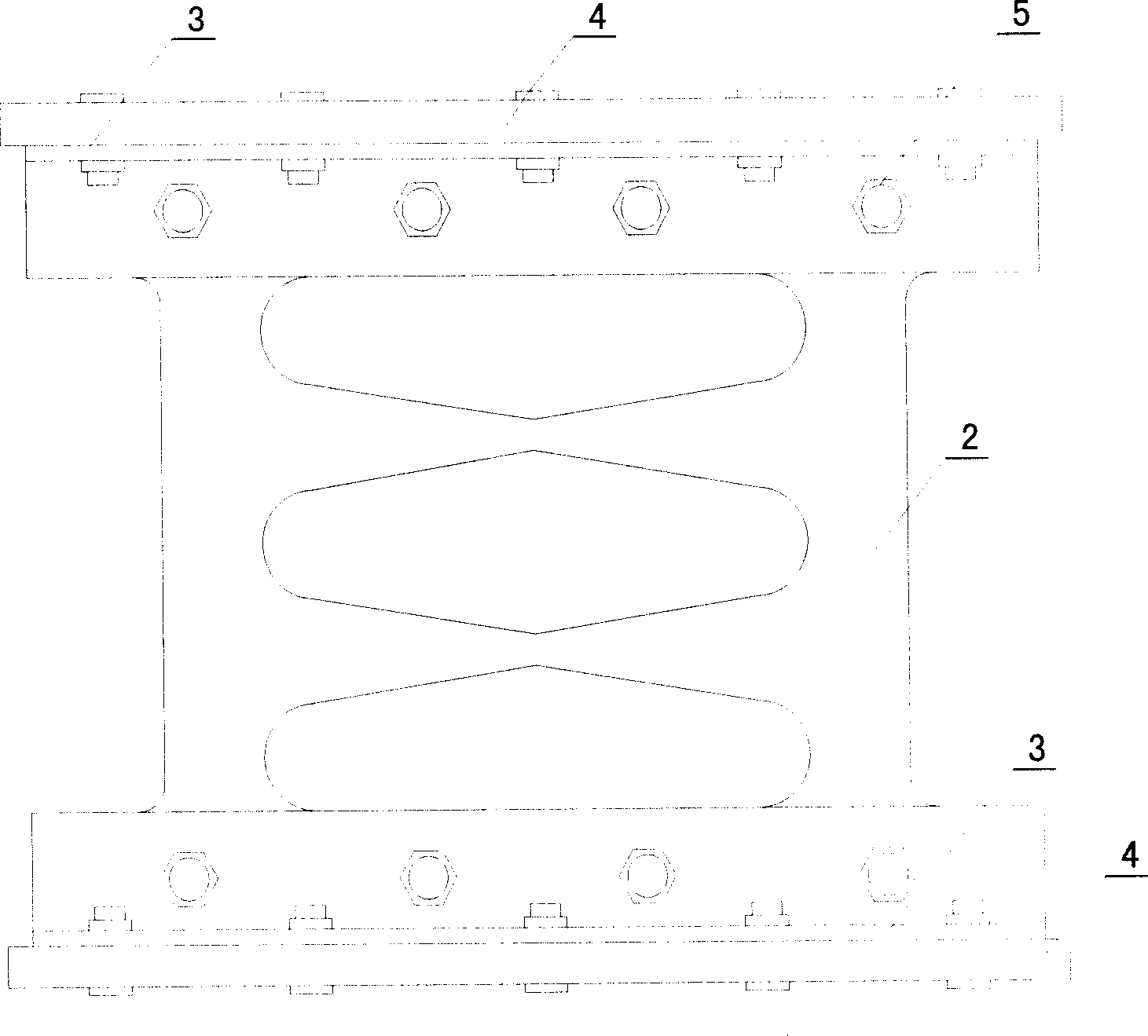

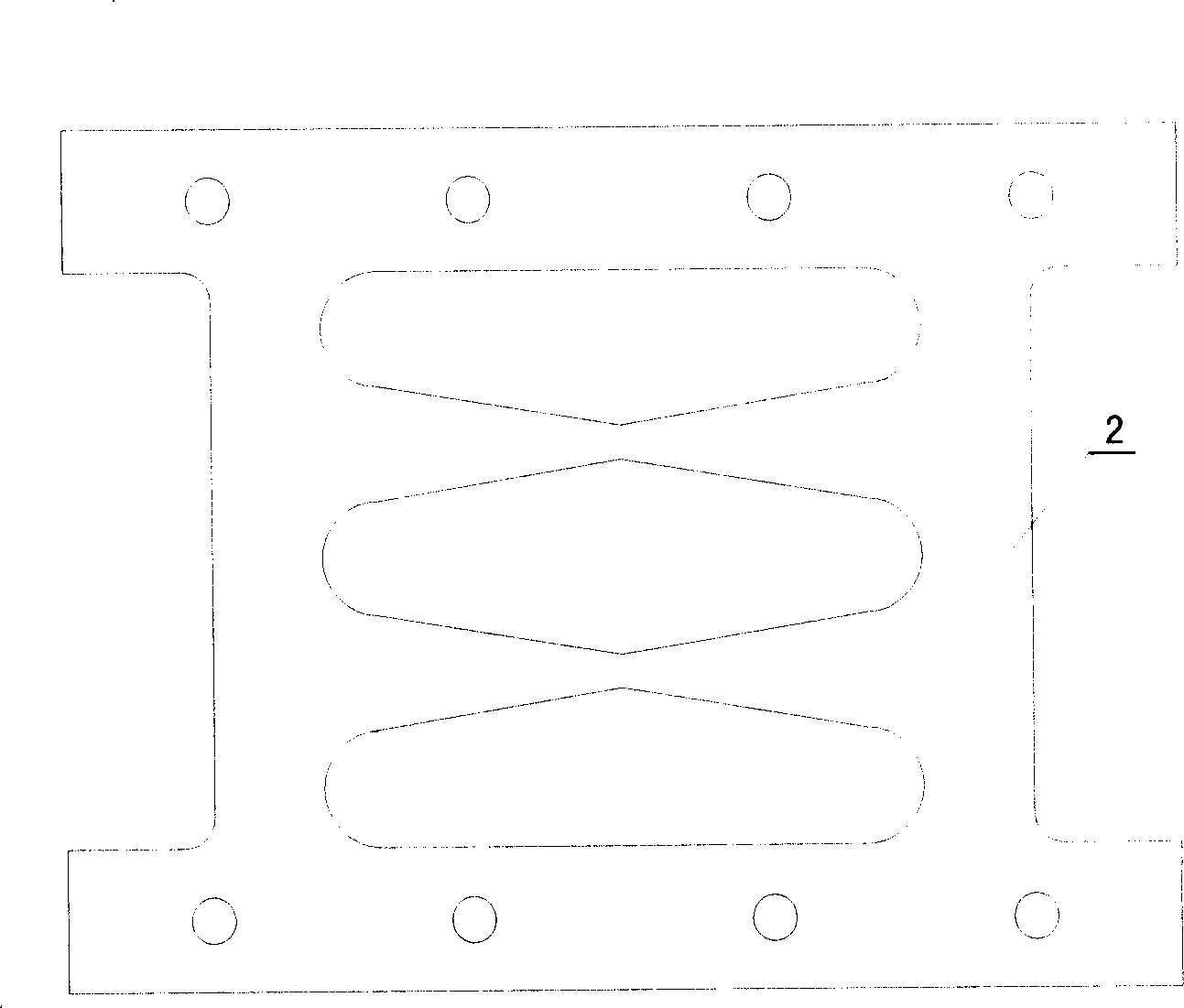

[0016] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

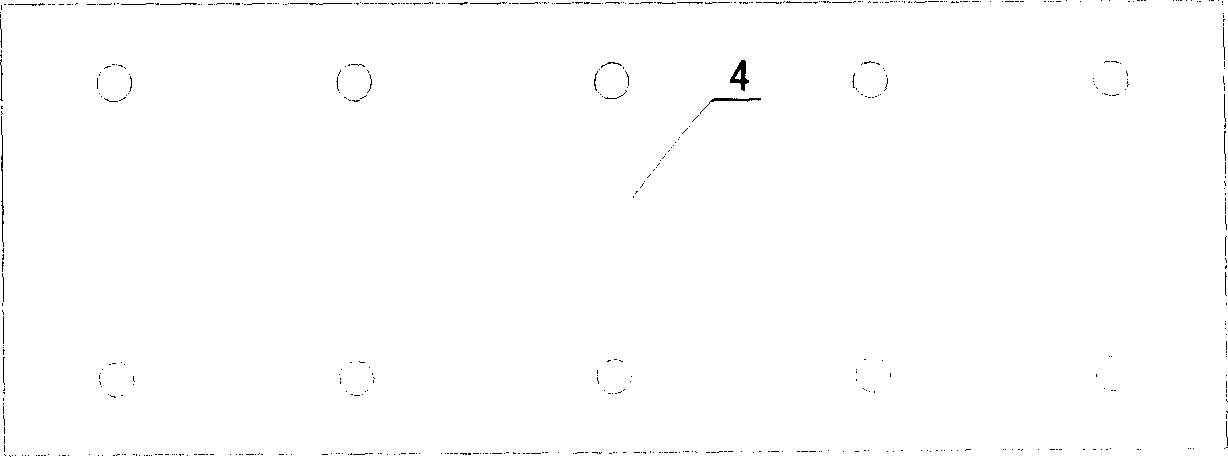

[0017] In specific implementation, first, the rectangular steel plate is processed into a double X shape, and the sharp corners are all transitioned in the form of rounded corners to make the energy-dissipating steel plate 2; secondly, the bolts are processed on the energy-dissipating steel plate 2, the angle steel 3, and the horizontal steel plate 4 holes; finally, connect the three together with bolt 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com