High speed power driven magnetic suspension centrifugal blower

A magnetic levitation and centrifugal technology, used in the fields of environmental protection, metallurgy, petroleum and chemical industry, can solve the problems of low efficiency of blower units, and achieve the effect of wide performance adjustment range, small volume and uniform gas supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

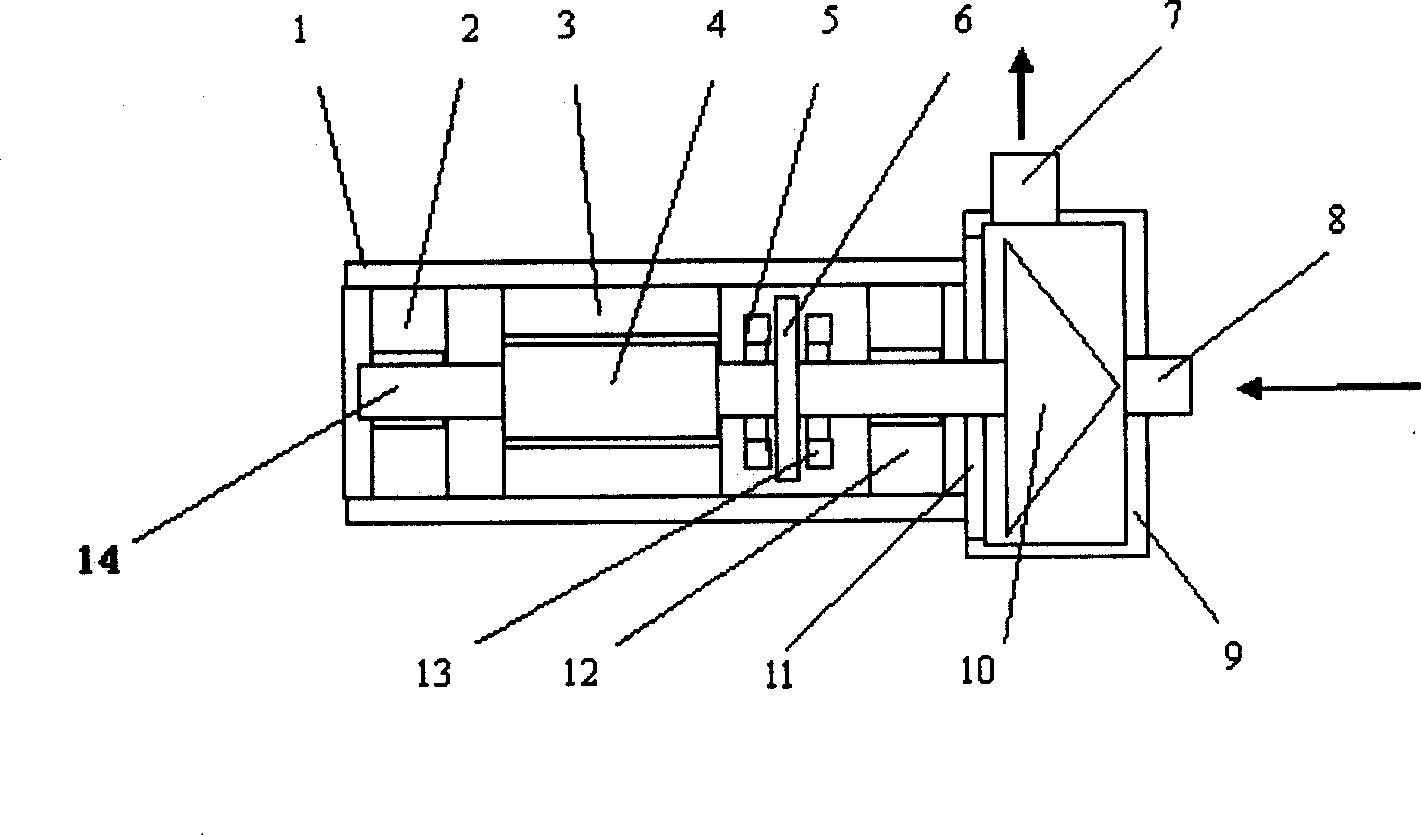

[0021] figure 1 Schematic diagram of the blower. It mainly includes: motor casing 1, first radial bearing 2, motor stator 3, motor rotor 4, first thrust bearing 5, thrust disc 6, exhaust port 7, air inlet 8, volute 9, impeller 10, Back plate 11 , second radial bearing 12 , second thrust bearing 13 , and main shaft 14 .

[0022] There are first radial bearing 2, motor stator 3, second radial bearing 12, first thrust bearing 5, and second thrust bearing 13 in the motor casing 1; the casing 1 passes through a back plate 11 and a volute 9 Connection; along the central axis of the shell space formed by the casing 1 and a volute 9, a main shaft 14 is arranged, and the motor rotor 4, the thrust disc 6, and the impeller matched with the motor stator 3 are sequentially installed on the main shaft 14. 10; the installation position of the impeller 10 is inside the volute 9; the volute 9 is provided with an axial inlet 8 and a radial exhaust 7.

[0023] In the figure, the motor housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com