Full automatic multifunction food processing machine

A multi-functional food and processing machine technology, applied in the direction of utensils, cooking utensils, beverage preparation devices, etc. Install temperature protection devices and other issues to achieve safe and reliable product performance, ensure the safety of use, and facilitate disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

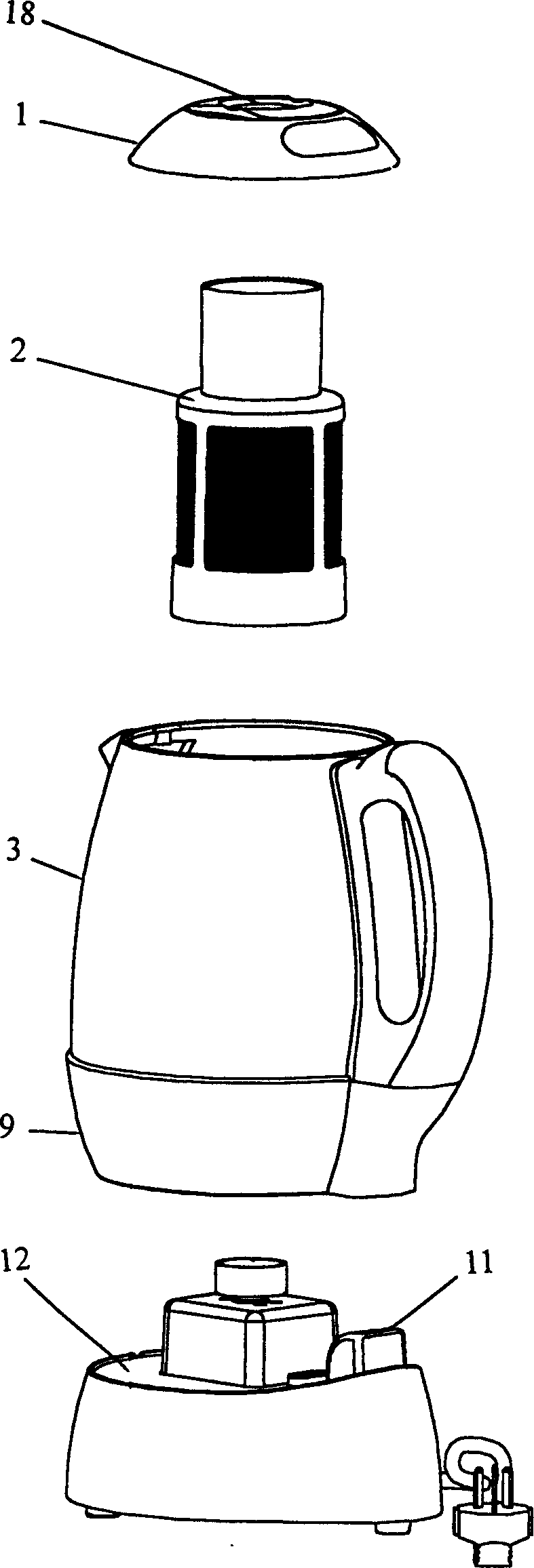

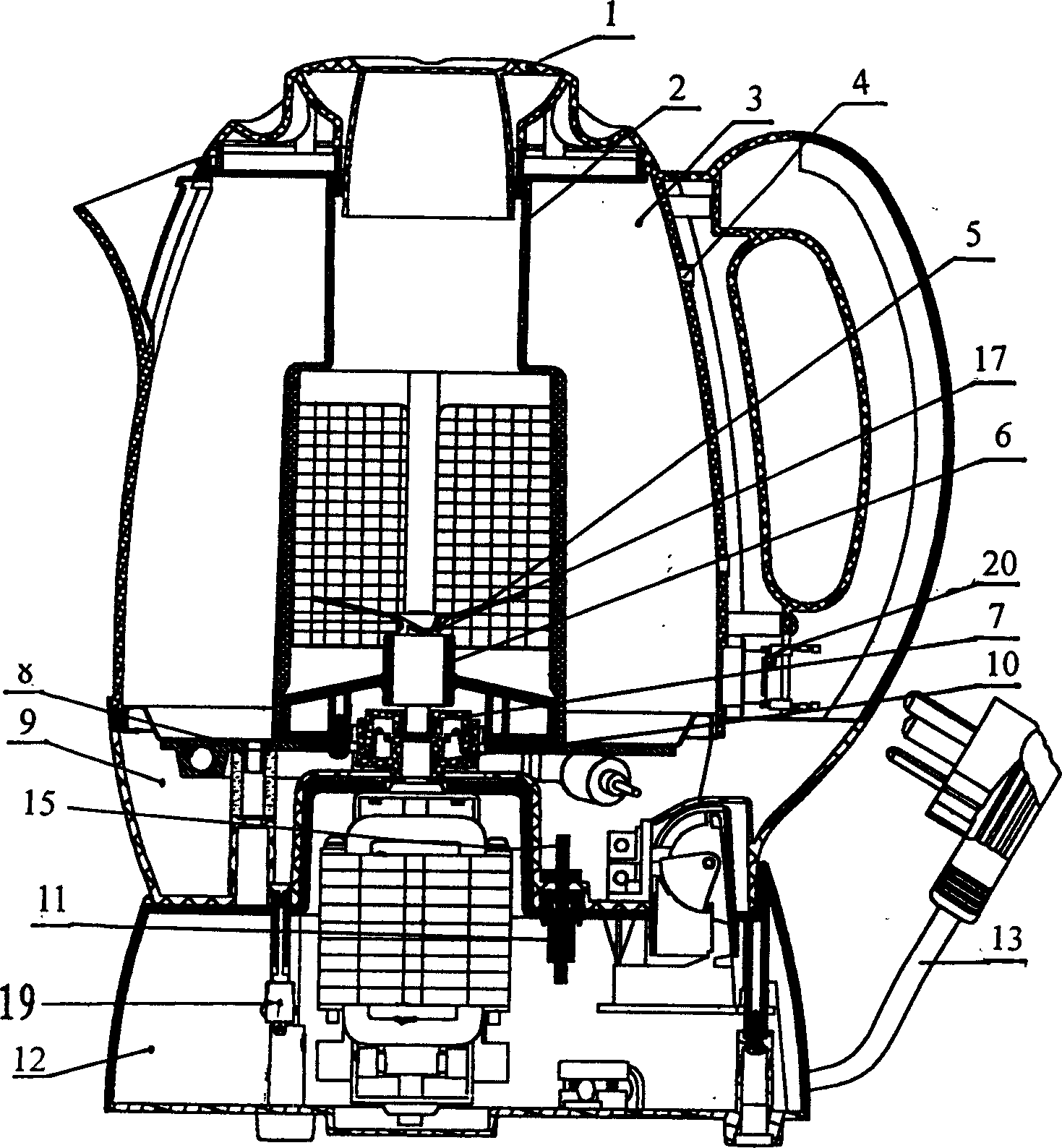

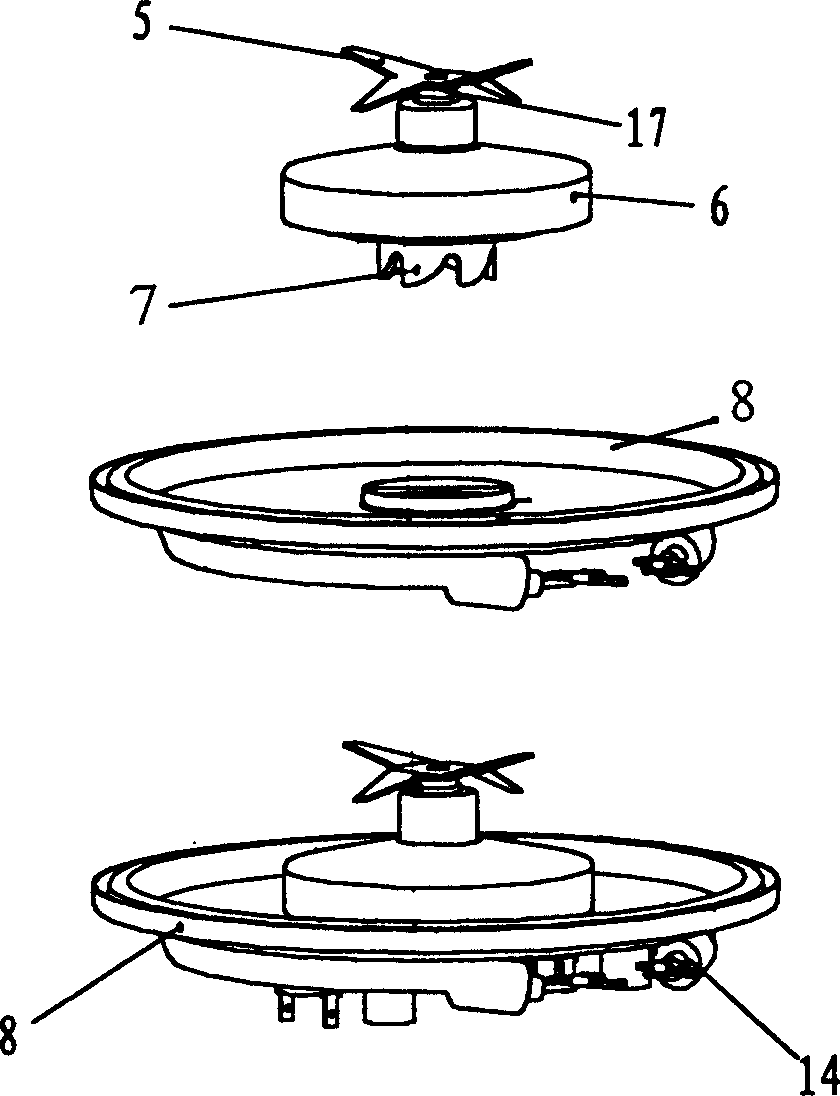

[0011] Such as figure 1 , 2 , 3, and 4, the present invention includes a base 12, a cup body 3 and an upper cover 1. Electric parts such as motor, transformer and power line 13, control circuit board, connection switch are installed in base 12. The heater is a heating plate 8 composed of an electric heating tube 14 and a metal plate. They can be made into one body through die-casting or other processes. The heating plate 8 is installed at the bottom of the cup body to become the bottom of the cup. Upper bottom cover9. In this way, the heating part and the electrical part are separated, so that the cup body and the base form a detachable structure. The two ends of the electric heating pipe are connected with electric plug 15, and this electric plug 15 is installed on the connection switch 11 on the base and corresponds up and down, and is inserted mutually. A self-locking switch 19 is connected in series between the power supply and the control circuit board. When the cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com