Groove capacitor and its manufacture

A technology of capacitors and trenches, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as damaging dielectric chemical reactions, achieve low wire resistance, fast access time, and increase performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

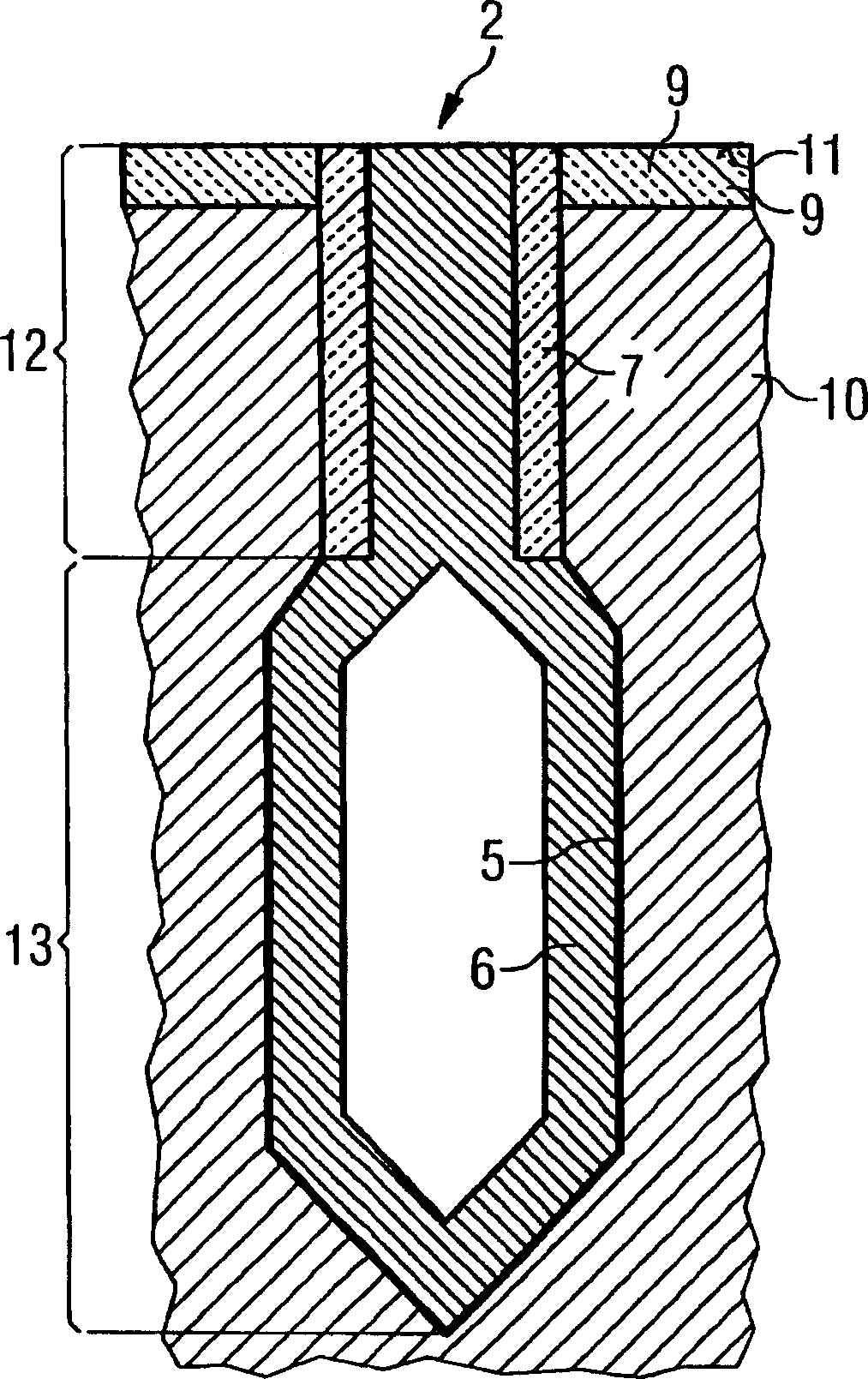

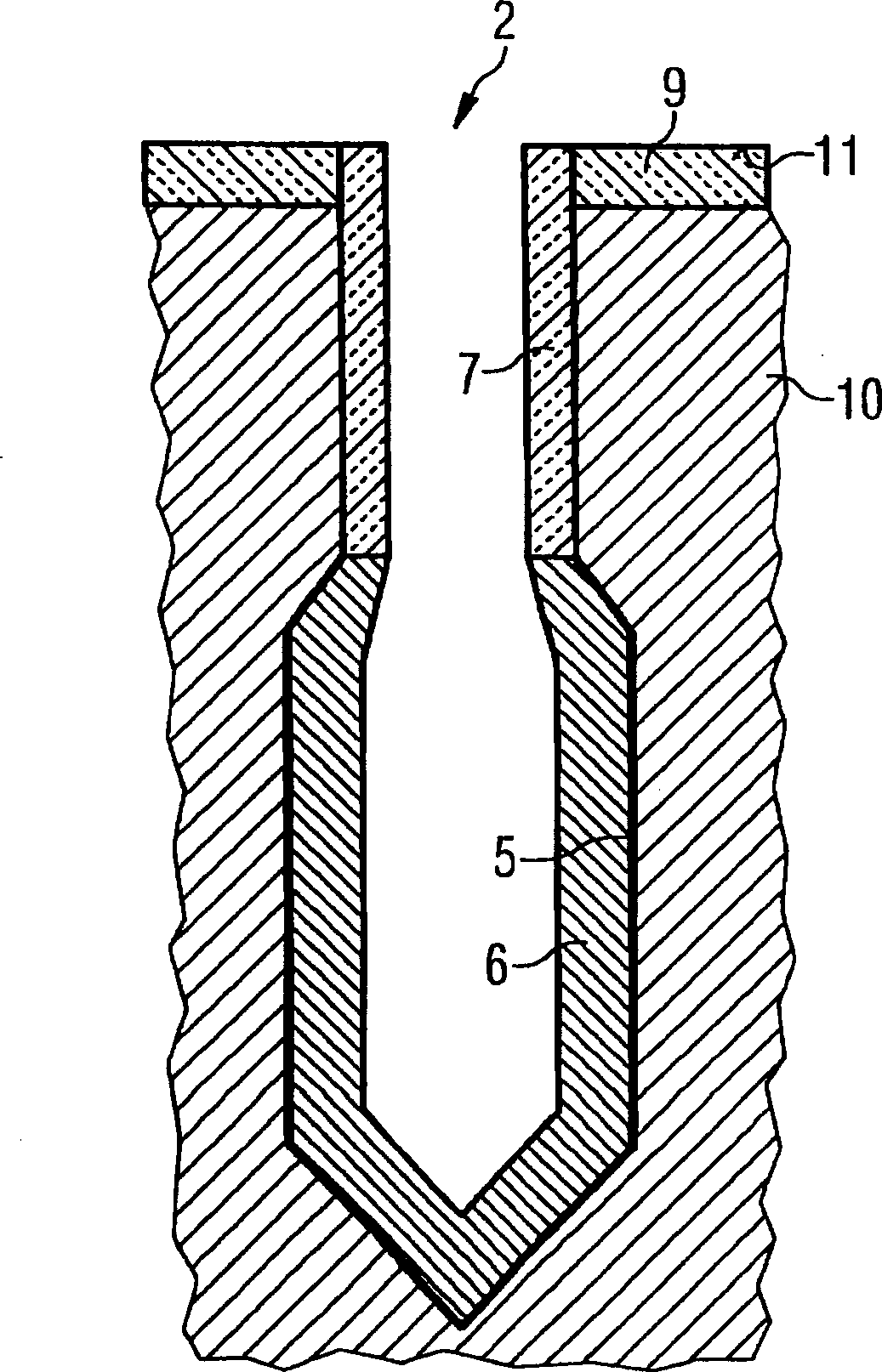

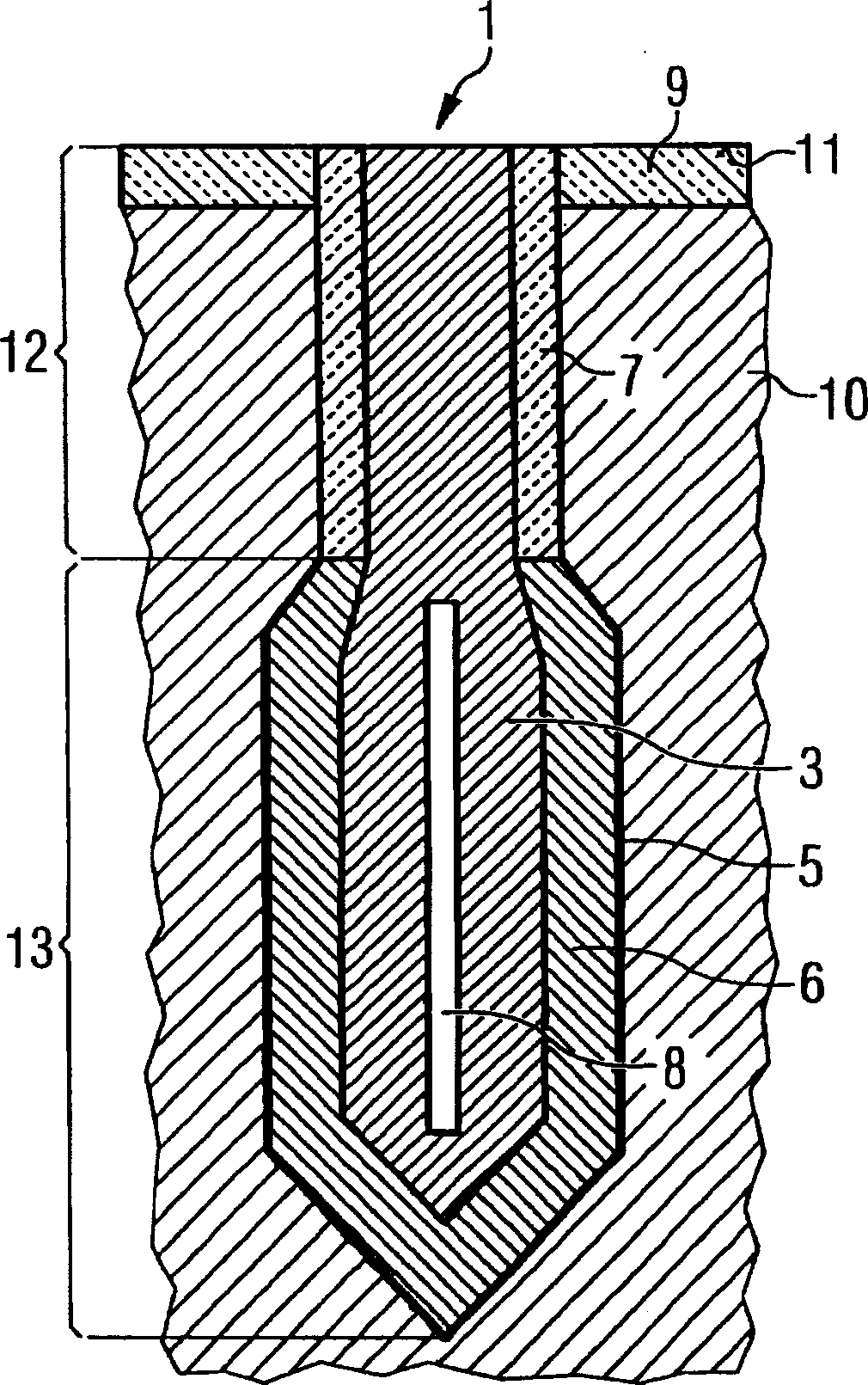

[0031] In order to manufacture a trench capacitor 1 in a semiconductor substrate 10, a hole trench 2 is introduced into the semiconductor substrate 10 from a substrate surface 11, and an external electrode, for example, as a "buried plate" , is, for example, provided in a section of the semiconductor substrate 10 adjacent to the hole trench 2 by depositing a region in the semiconductor substrate 10, furthermore, the hole trench 2 There is an active region 13 extending into the semiconductor substrate 10 and lined with a dielectric layer 5 such as, for example, metal oxides and oxides of rare earths, such as Al 2 o 3 , HfO 2 , ZrO 2 , La 2 o 3 , can be provided as the dielectric layer 5 . Next, a neck region 12 is located between the substrate surface 11 and the active region 13 . In this exemplary embodiment of the method according to the invention, however, a silicon nitride layer 9 is provided on the semiconductor substrate 10, which in this case comprises crystalline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com