Integral phyical chemical treating method by bathing waste water reutilization

A technology of physical chemistry and treatment methods, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. less problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

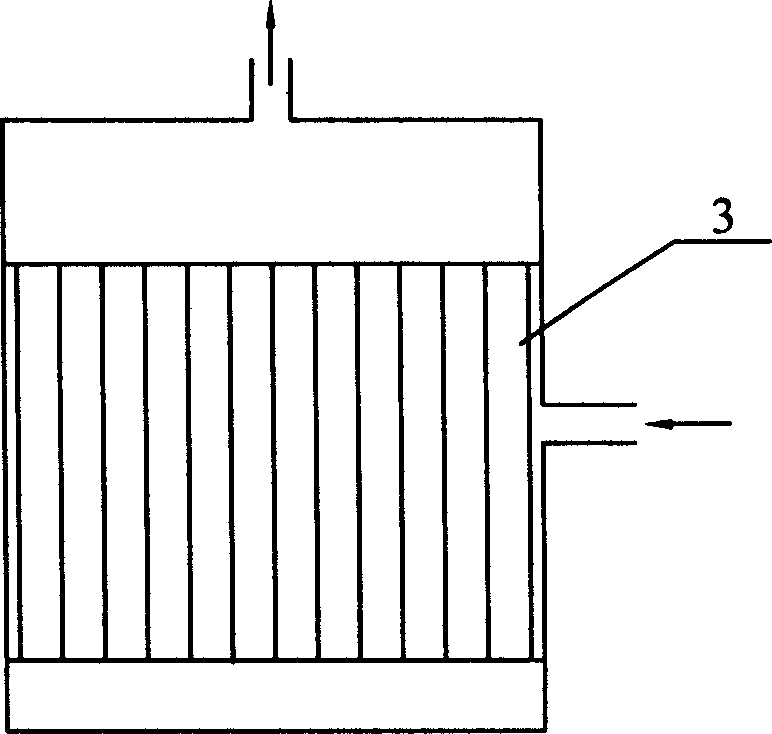

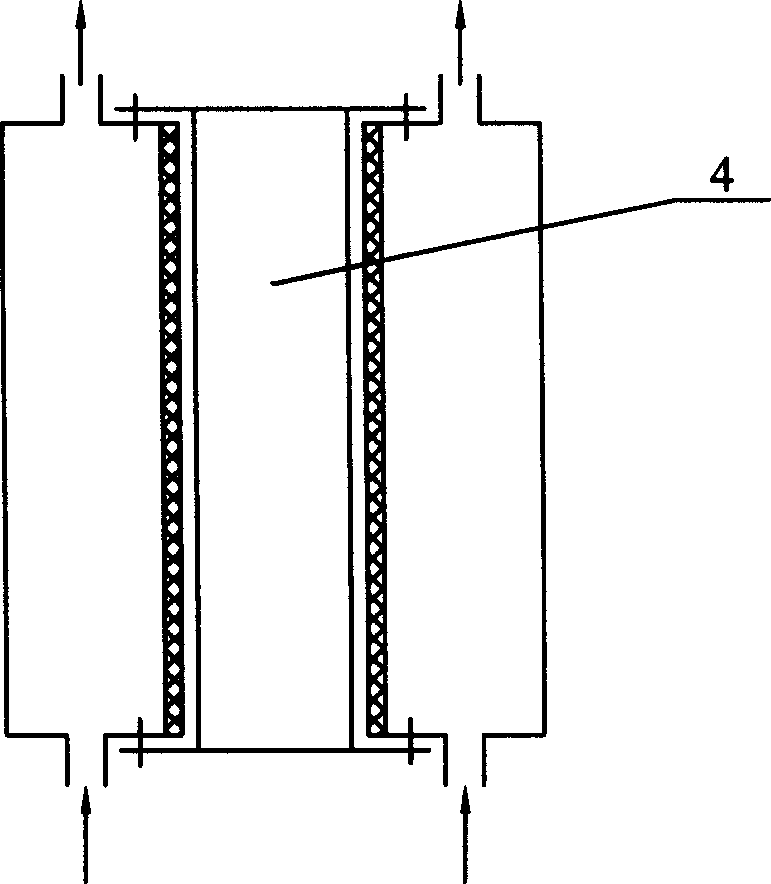

[0005] Specific embodiment one: an integrated physical and chemical treatment method for reuse of bathing wastewater, which is completed through the following steps: (1) drop into polyferric chloride in wastewater, and carry out coagulation and precipitation; (2) the water after precipitation Filter through anthracite-quartz sand double-layer filter material; (3) filtered water enters the container containing granular activated carbon adsorption column and zeolite ion exchange column for activated carbon adsorption and ion exchange; (4) treated water enters ultrafiltration (5) UV disinfection of water.

specific Embodiment approach 2

[0006] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in the process of coagulation and sedimentation, the dosing ratio is 18-22 mg of polyferric chloride per liter of waste water, and the precipitation time is 10-17 minutes. Preferably, 20 mg of polyferric chloride is added per liter of wastewater, and the precipitation time is 15 minutes. Other steps are the same as those in Embodiment 1.

specific Embodiment approach 3

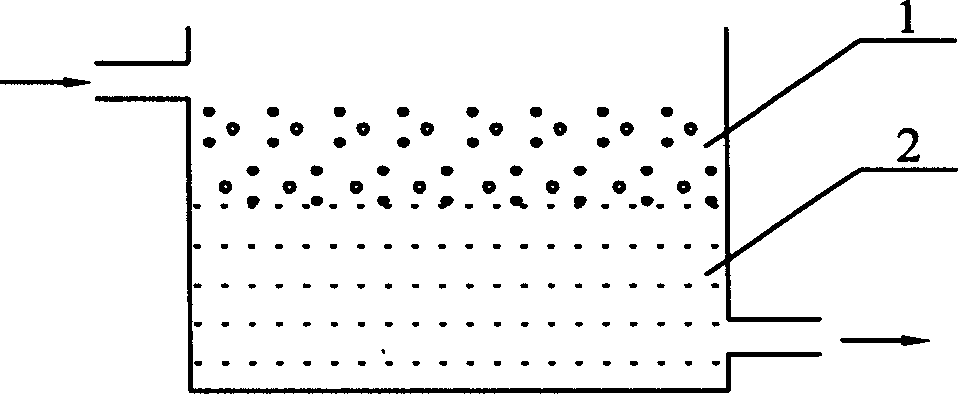

[0007] Specific implementation mode three: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that in step (2), the quartz sand 2 with a particle size of 0.9 to 1.2 mm and the anthracite 1 with a particle size of 1.5 to 2 mm form an anthracite-quartz sand double-layer filter material, The precipitated water passes through the filter material at a filtration speed of 10-15 m / hour. Other steps are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com