Micro lens and making method thereof, optical device and optical transmitting device

A technology of micro lenses and optical devices, applied in the directions of optics, lenses, optical components, etc., can solve the problems of difficult shapes, difficult to form micro lenses, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

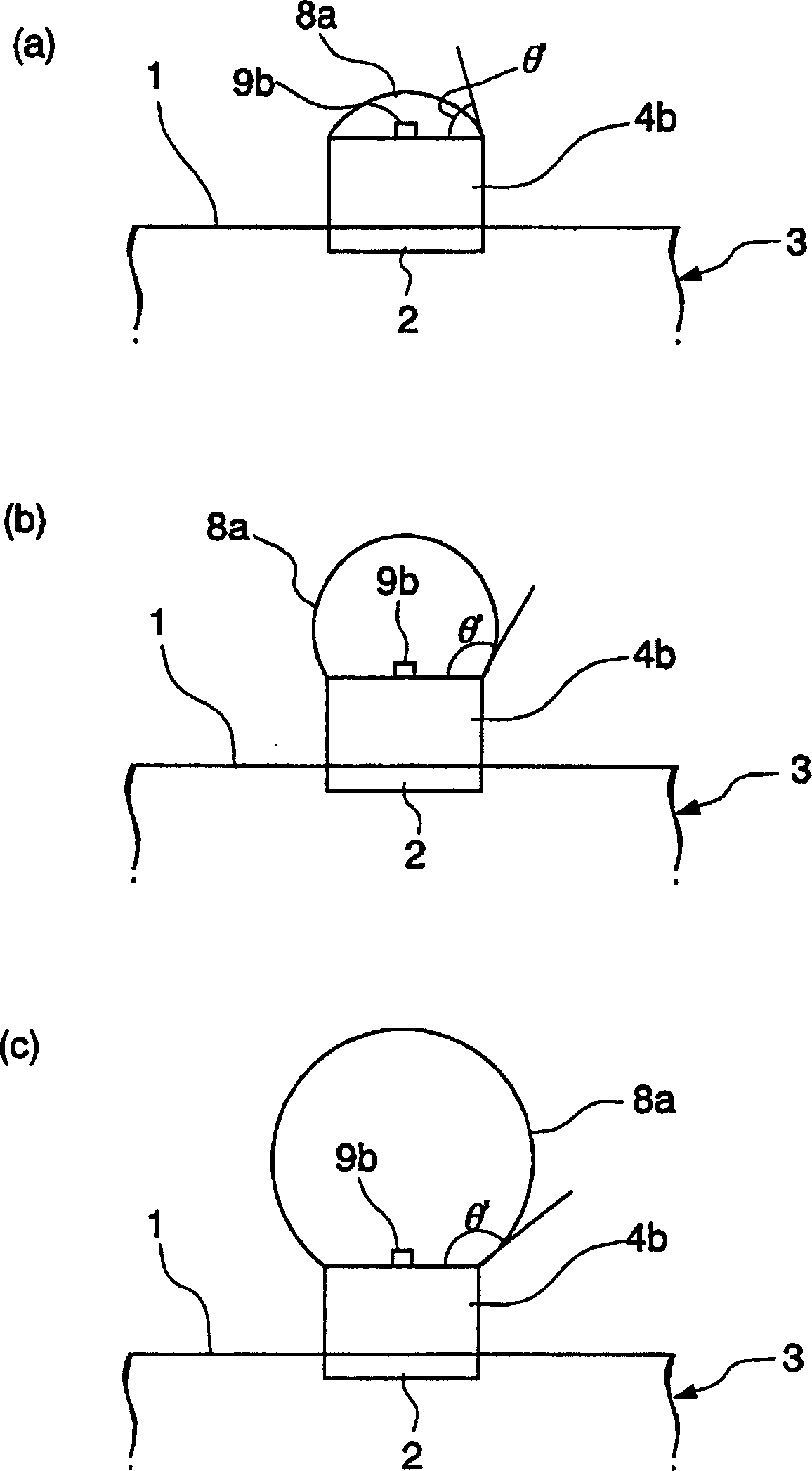

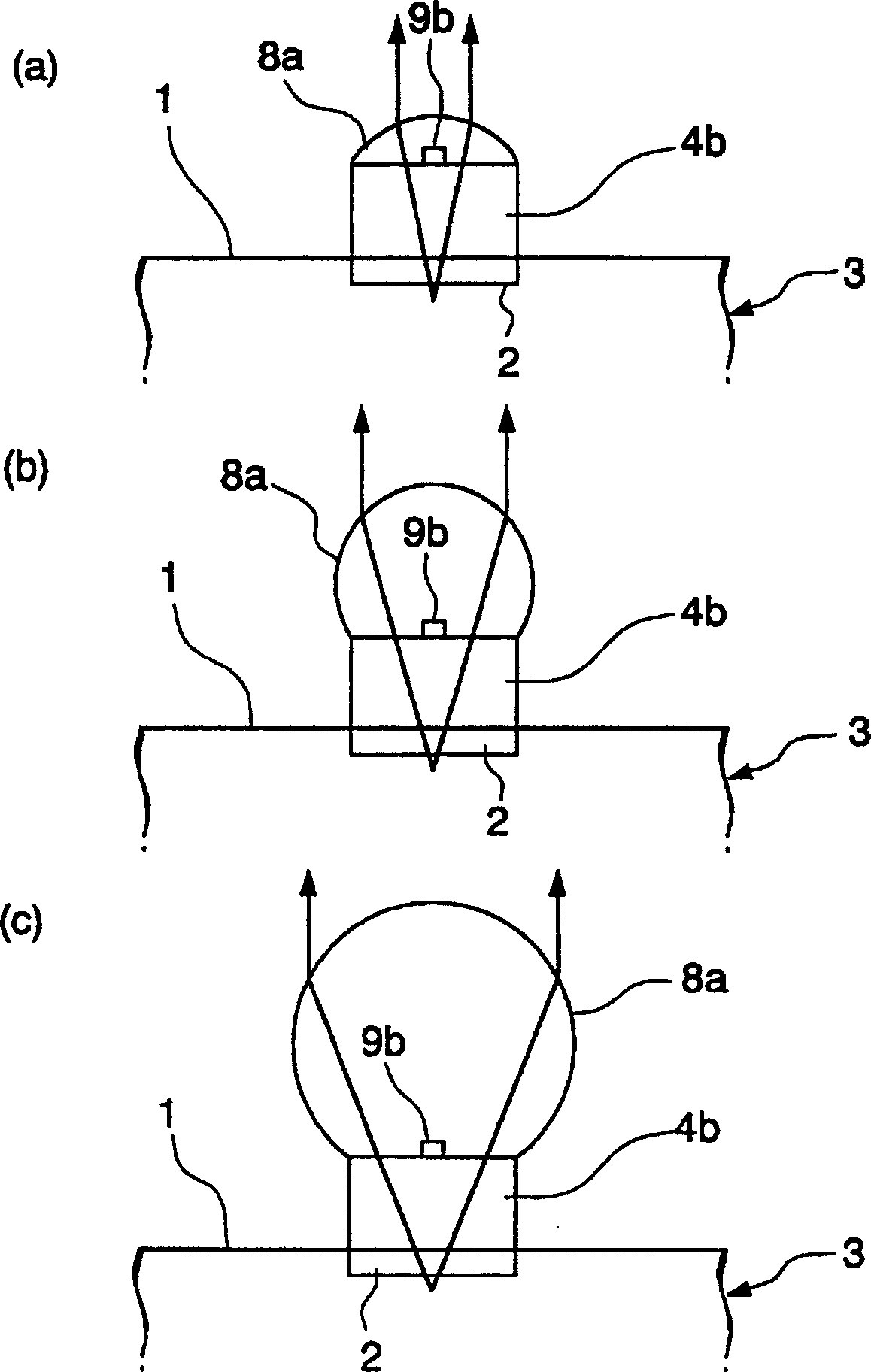

[0043] micro lens

[0044] figure 1 It is a microlens according to an embodiment of the present invention, and is a cross-sectional view showing main parts of lens members 8a of various shapes.figure 1 The various shapes of the lens members shown in (a) to (c), that is, from the flat shape ( figure 1 (a)), the side is close to the shape of a hemisphere ( figure 1 (b)) and a shape with a nearly spherical side ( figure 1 (c)).

[0045] exist figure 1 In (a) to (c), the substrate 3 has a surface on which the base member 4b can be formed, specifically, a glass substrate or a semiconductor substrate, and a substrate on which various functional films or functional elements are formed. In addition, the surface forming the base member 4b may be a flat surface or a curved surface, and the shape of the base body 3 itself is not particularly limited, and various shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com