Magnetron

A magnetron and inductor technology, applied in the field of magnetron, can solve the problems of insulation failure, high frequency absorption element 2 cracks, noise attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

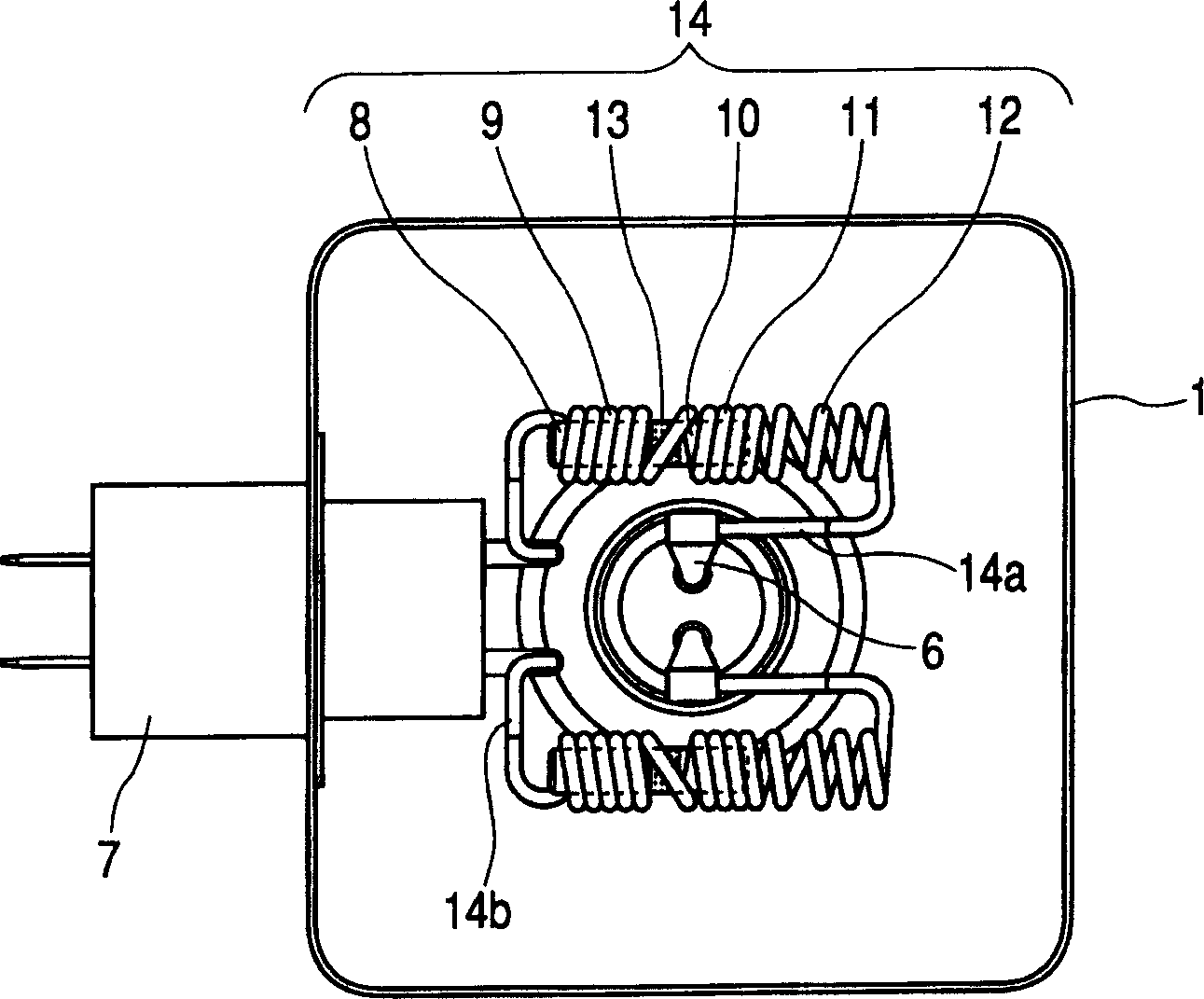

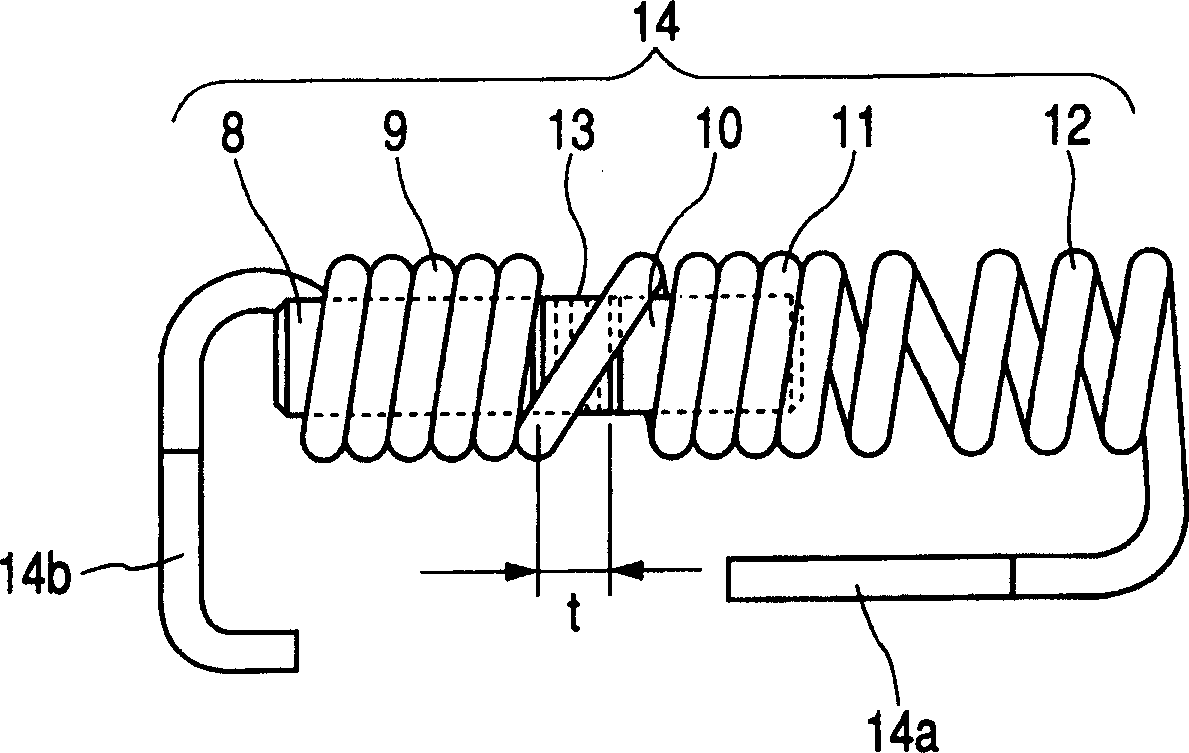

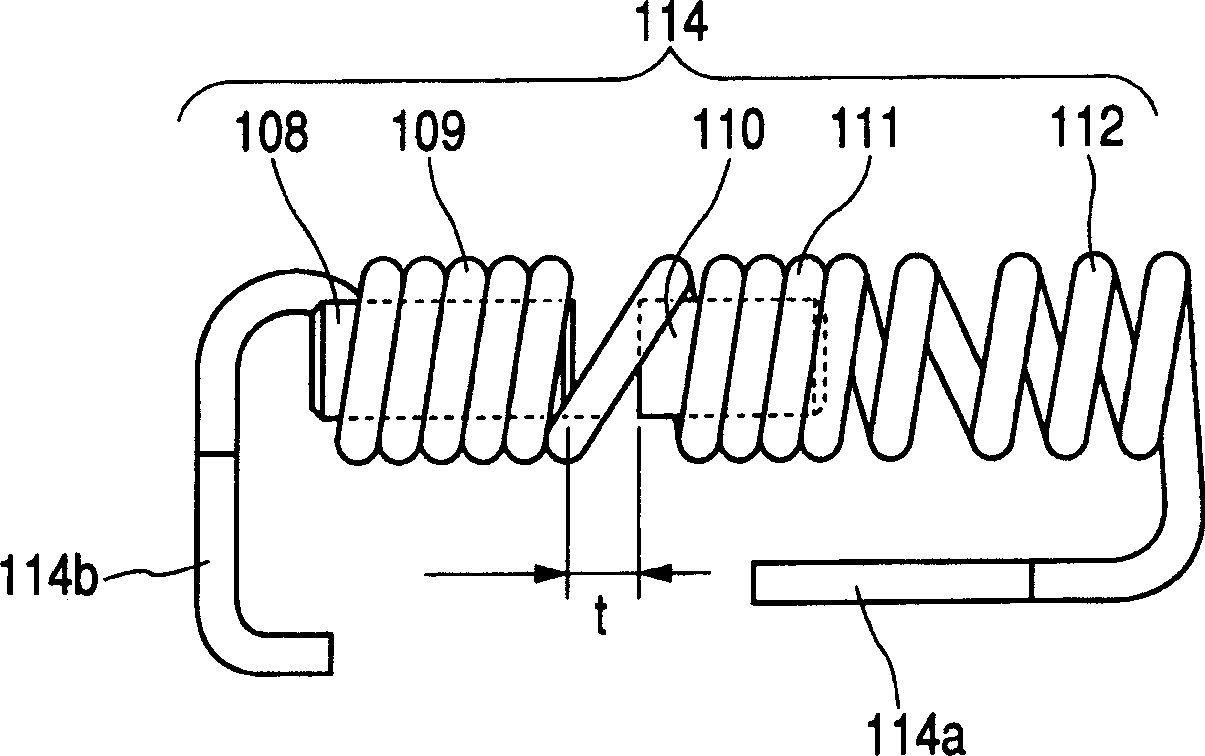

[0028] figure 1 is a plan view schematically showing the arrangement of the LC filter circuit in the magnetron according to the first embodiment of the present invention. Figure 2A is a front view showing key components of the choke coil in the magnetron according to the first embodiment of the present invention. image 3 is a graph showing the amount of noise attenuation at the frequency bands of 700 MHz and 500 MHz with respect to the change in the size of the gap between the first and second core inductors in the choke coil in the magnetron of the present invention situation. Figure 4 is a graph showing how the amount of noise attenuation changes with respect to frequencies from 30 MHz to 1 GHz when the magnetron according to the first embodiment is installed in a microwave oven. Throughout the drawings to be referred to later, for the sake of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com