Metal greasy dirt cleaning agent and its production method

A technology for metal oil stains and cleaning agents, applied in the field of cleaning agents, can solve the problems of increasing the amount of water waste in polluting the environment, poor cleaning effect of heavy oil stains, and difficult to clean up, and achieves reduction of sewage discharge, easy operation, and less foam. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment.

[0017] 1. Metal oil cleaning agent

[0018] Its ingredients include degreasers and surfactants.

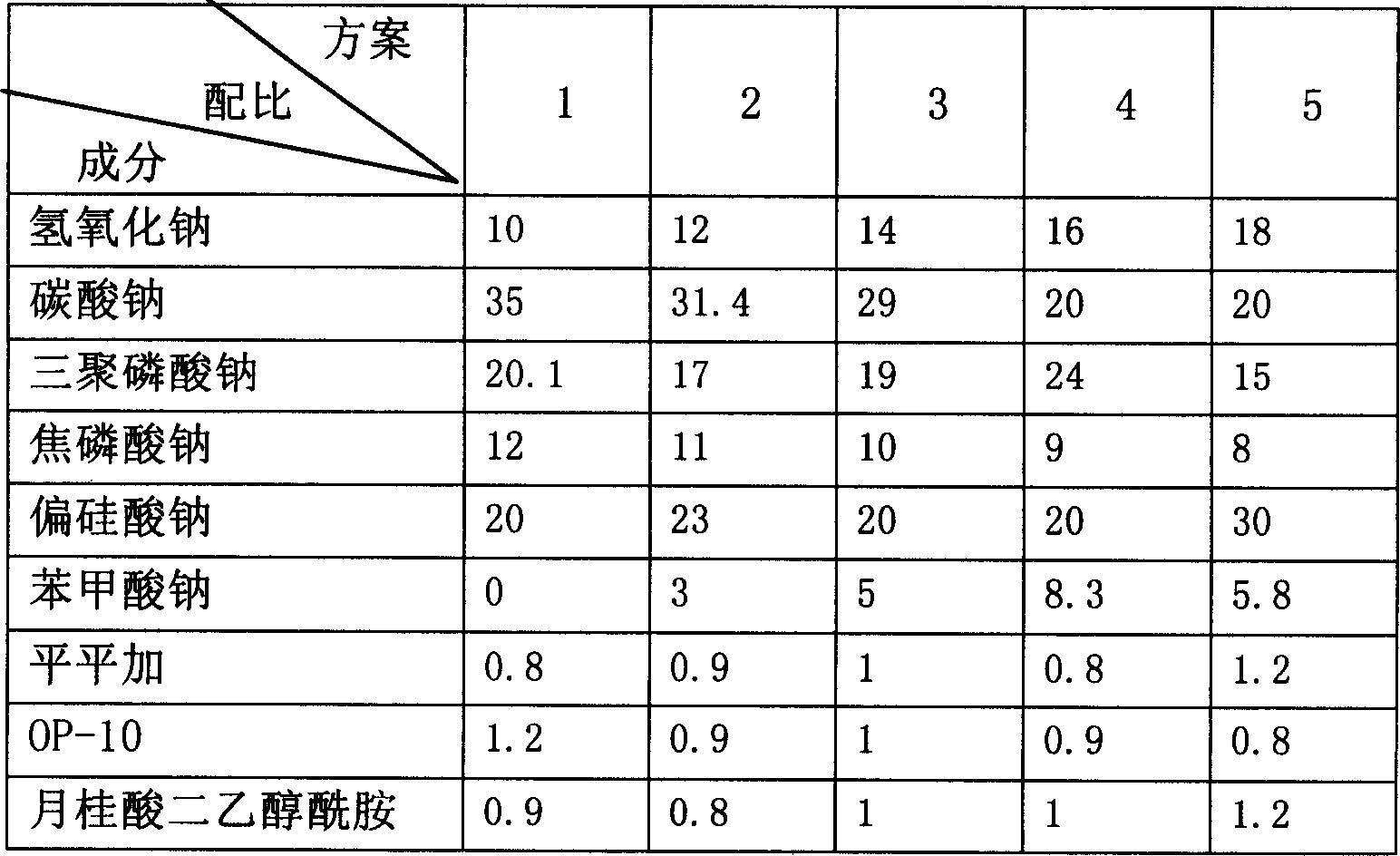

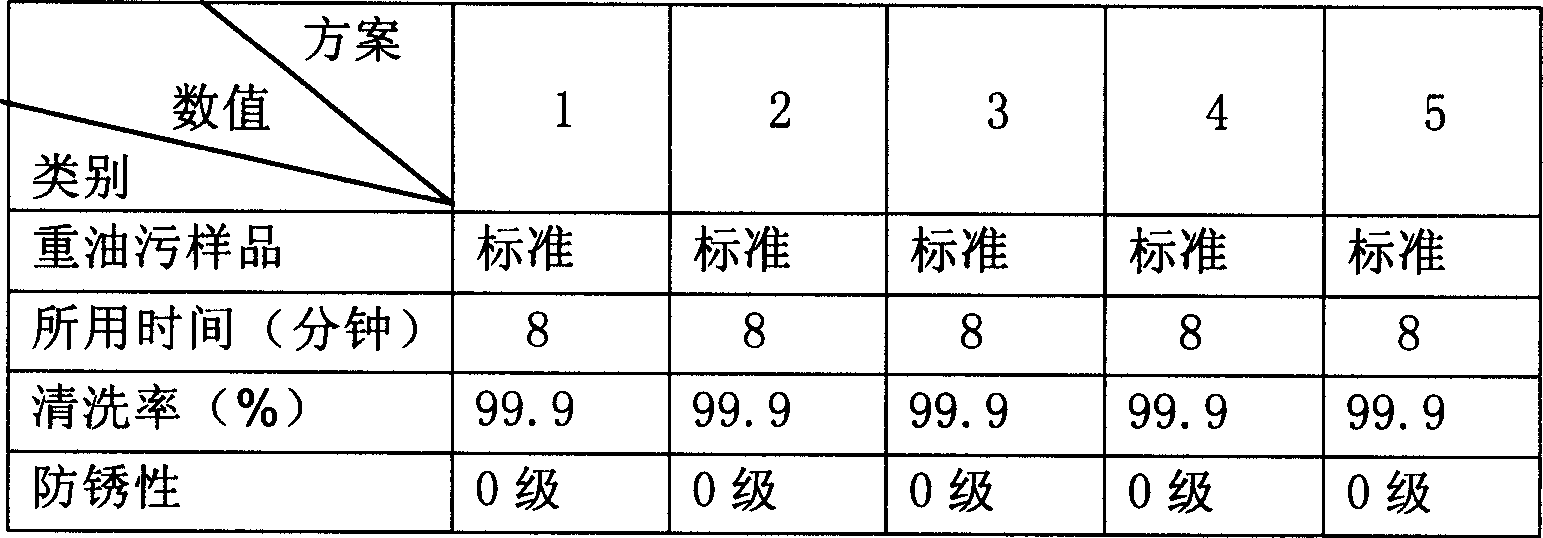

[0019] The degreaser includes (% by weight): 10-18 sodium hydroxide, 20-35 sodium carbonate, 15-24 sodium tripolyphosphate, 8-12 sodium pyrophosphate, and 20-30 sodium metasilicate. Among them, the combination of sodium hydroxide 14, sodium carbonate 29, sodium tripolyphosphate 19, sodium pyrophosphate 10, sodium metaphosphate (sodium metasilicate) 25, and sodium benzoate 5 is the best.

[0020] Surfactants include (% by weight): Pingpingjia, OP-10 and lauric acid diethanolamide are all 0.8-1.2; wherein the combination of Pingpingjia, OP-10 and lauric acid diethanolamide is the best.

[0021] 2. Production method of metal oil stain cleaning agent

[0022] Its steps include:

[0023] a. Prepare the raw materials according to the formula (Table 1), the raw materials include degreasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com