Fiber glass motion transducer

A technology of displacement sensor and optical fiber, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of low precision and sensitivity, small range, poor stability, etc., and achieve strong anti-interference ability, large range and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

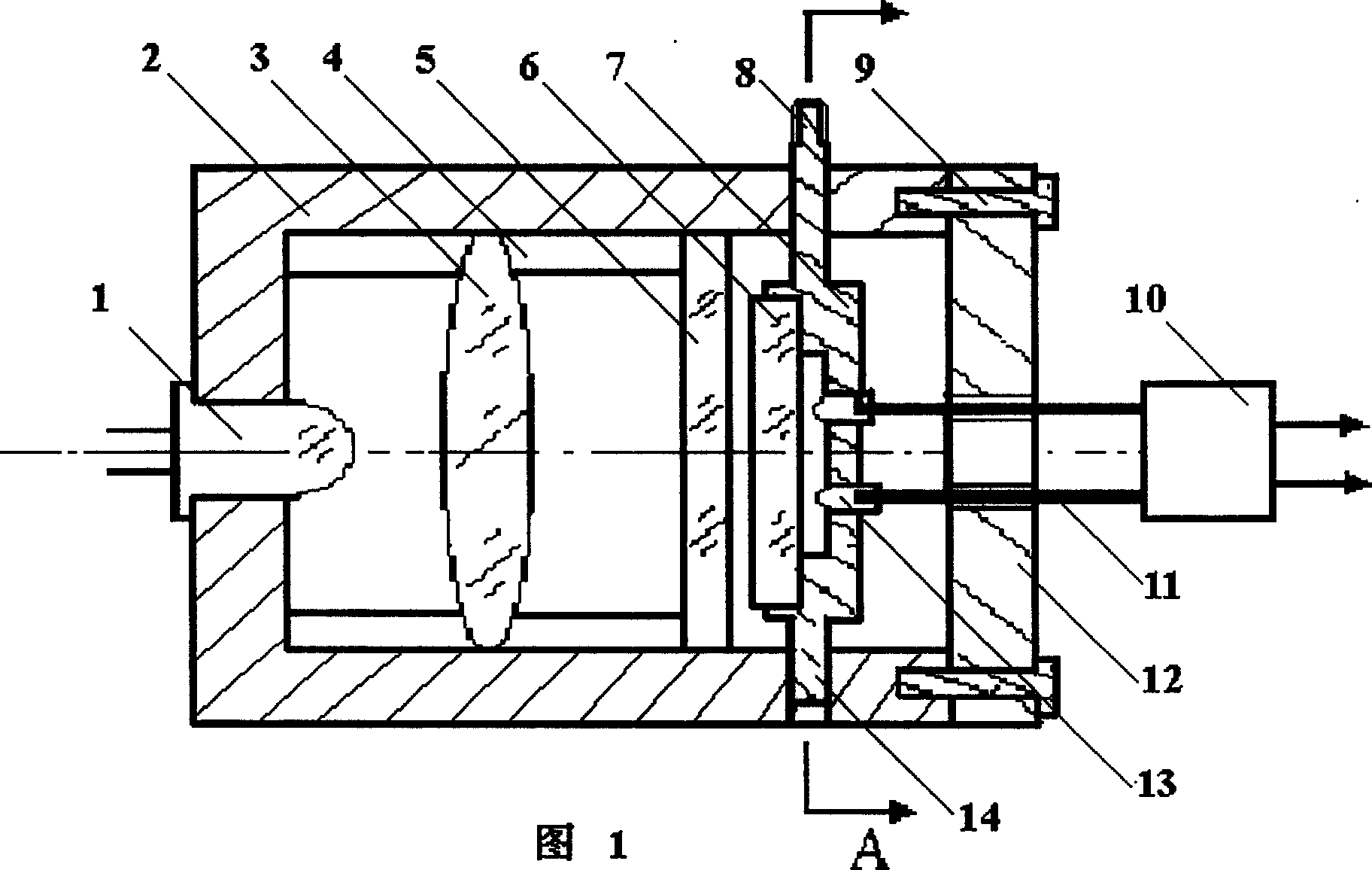

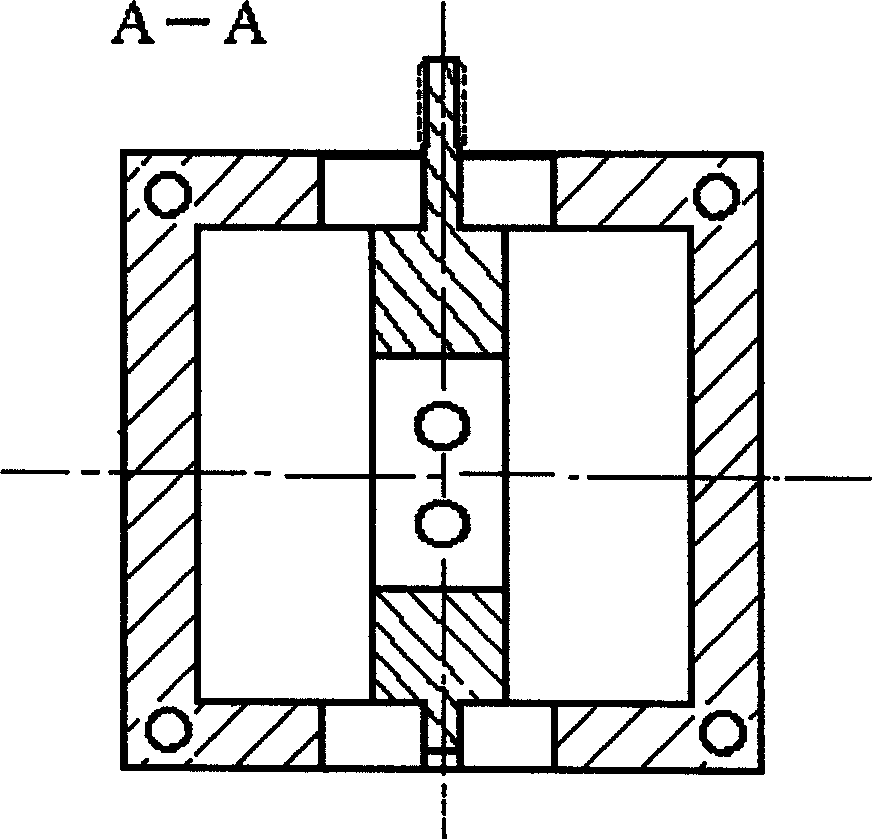

[0018] This embodiment is mainly composed of a light source 1, a lens 3, a main grating 5, an indicating grating 6, a photoelectric conversion and direction identification circuit instrument 10, a self-focusing lens 13, a multimode optical fiber 11 and a box body 2. During specific implementation:

[0019] The casing 2 made of metal is square, and a cover plate 12 is arranged at one end. The bottom of the box body 2 has through holes for placing the light source 1 along both sides of the center line, and there are displacement grooves 14 on the side walls, and the displacement grooves on one side are through holes, and the other side is a blind hole; There are also through holes for placing multimode optical fibers 11 on both sides of the center line. The cover plate 12 is connected with the box body 2 by screws.

[0020] A light source 1 is formed by illuminating light-emitting diodes with a wavelength of 940 nm, and is glued and fixed on the bottom of the box body 2 . An o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com