Method for using solid/liquid coal double fuel for circulation fluidized bed boiler

A circulating fluidized bed and boiler combustion technology, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, combustion methods, etc., can solve problems such as increasing boiler operation and maintenance costs, affecting boiler life, and supplying steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

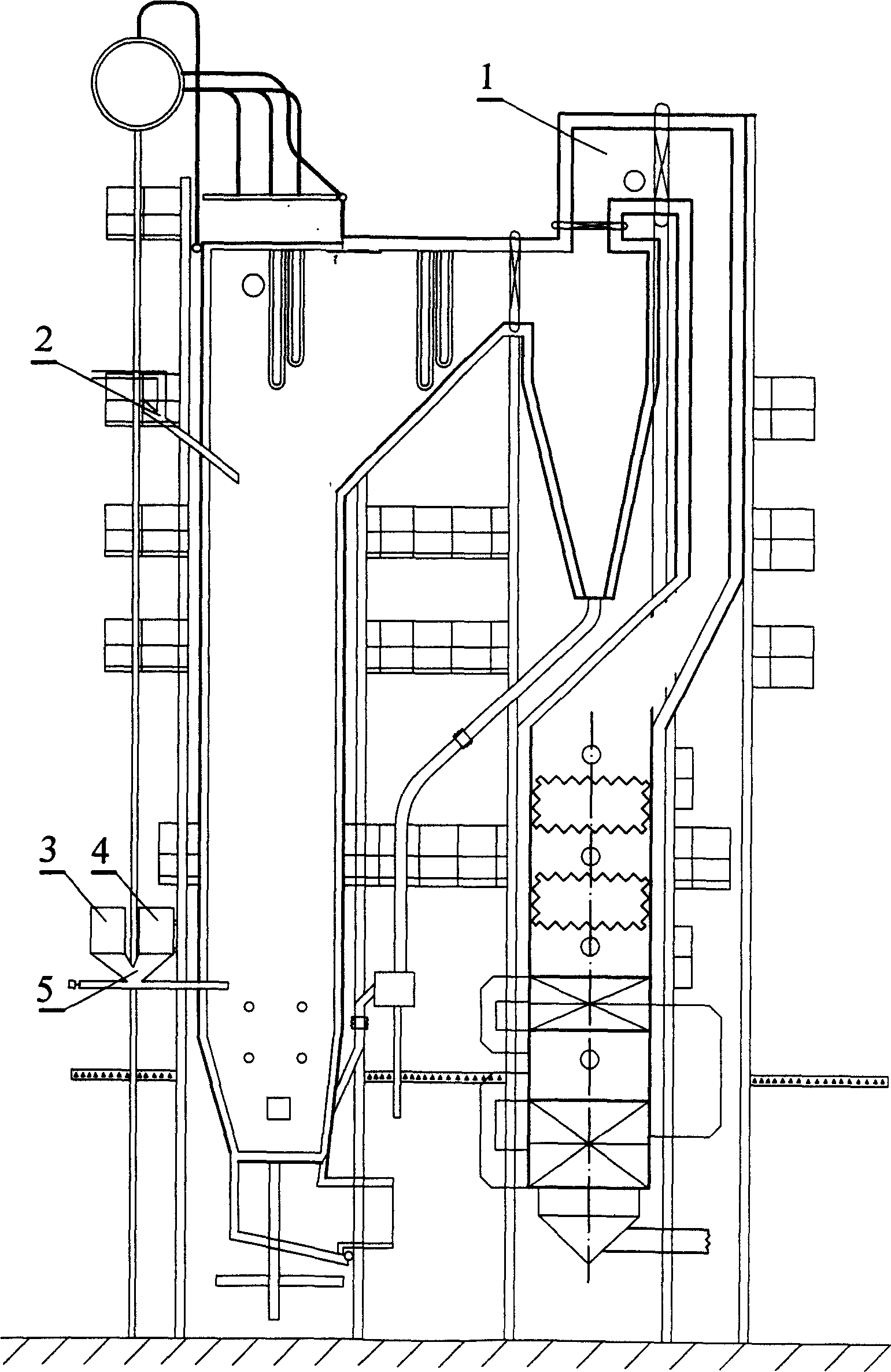

Embodiment Construction

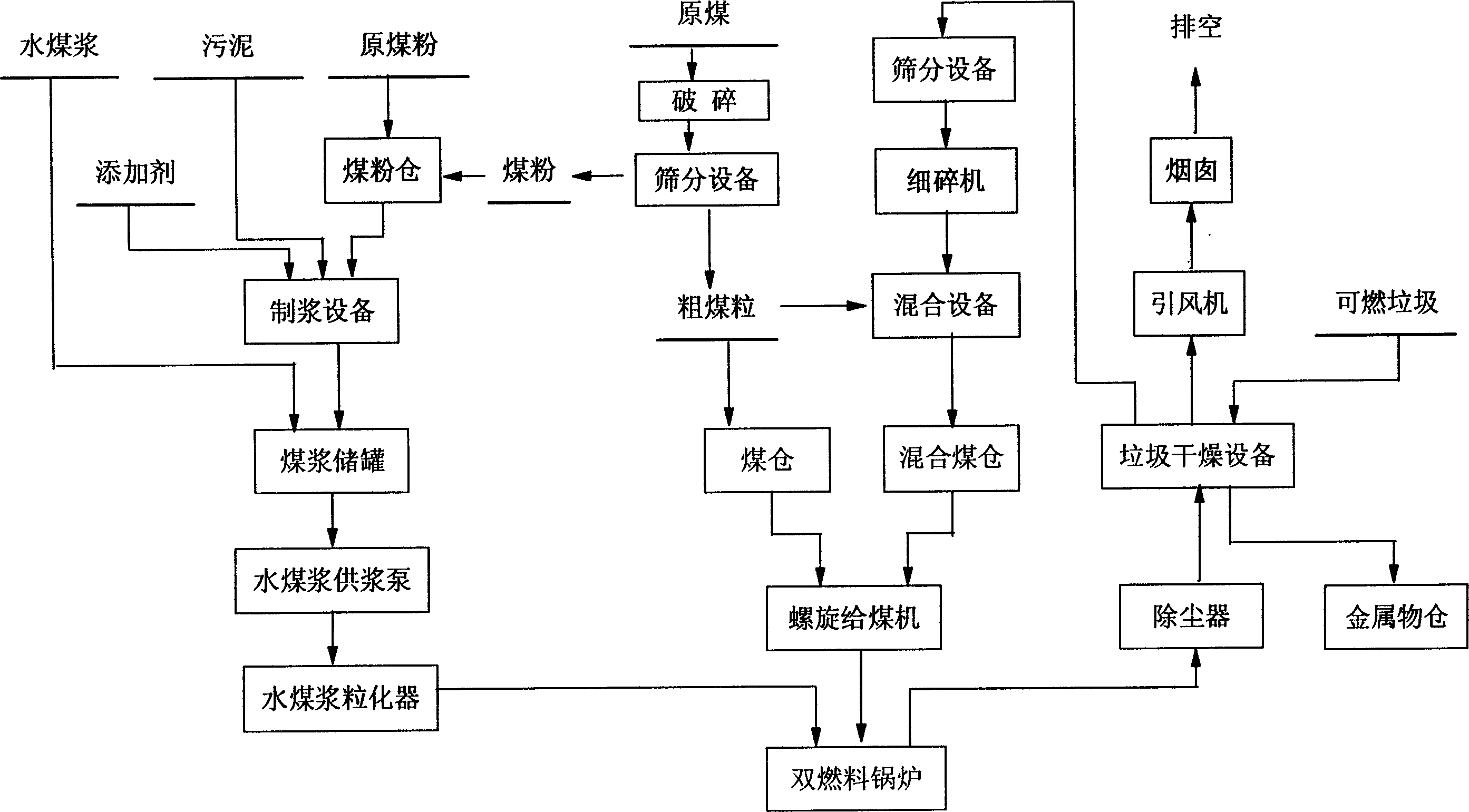

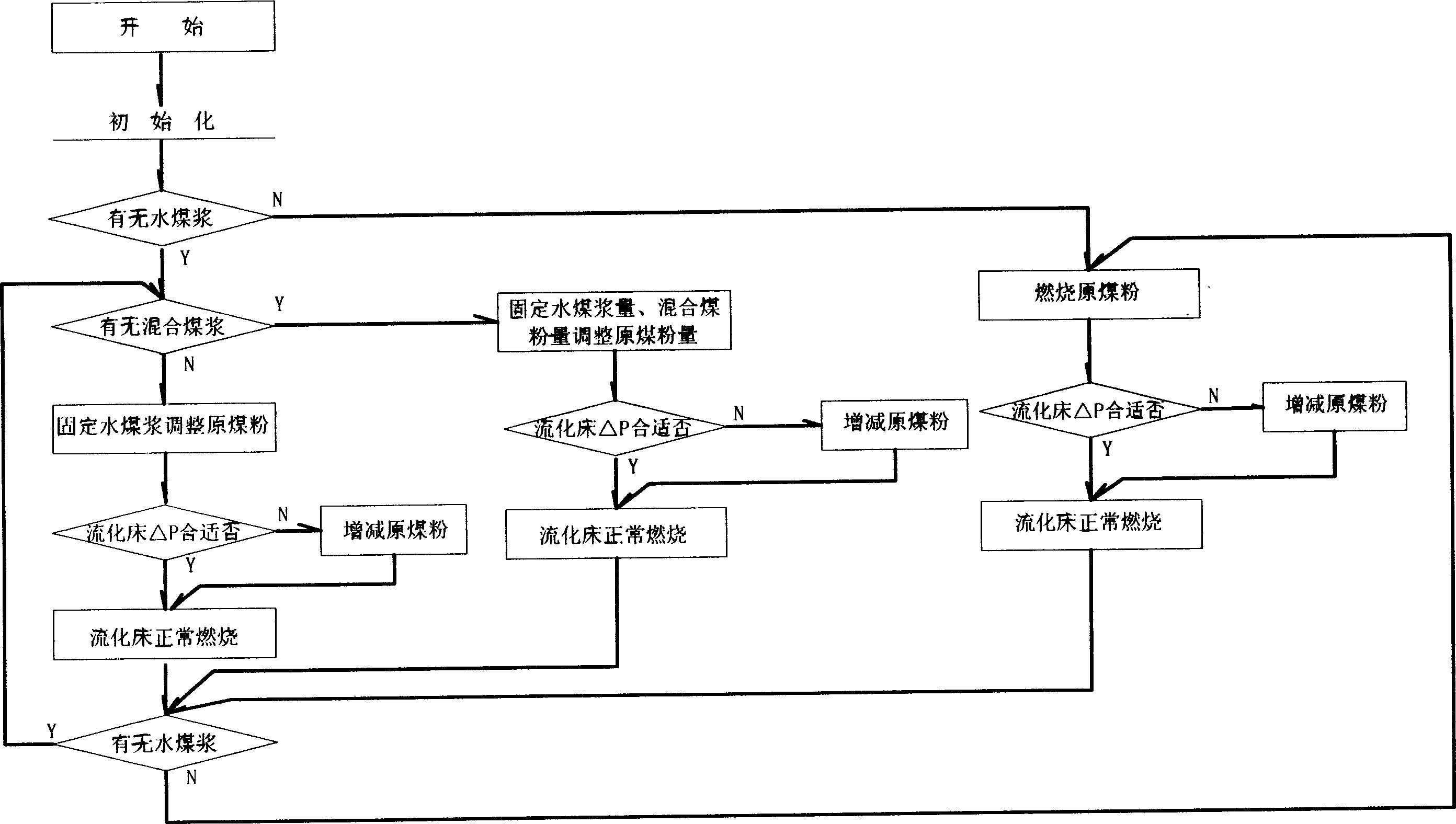

[0031] A paper mill needs two 35-ton / hour steam boilers. The paper mill produces 45 tons of sludge and 50 tons of combustible garbage (mainly plastic) every day. The solid and liquid fuel supply device of this patent have been installed in 2 sets of 35 tons / hour circulating flow sleeper bed boilers of this paper mill. The paper mill installs a slurry tank and a slurry storage tank, and puts papermaking sludge, coal powder, papermaking waste liquid and additives into the pulping tank in proportion to make sludge with a calorific value of 17000-19000KJ / kg Coal water slurry, the sludge coal water slurry is transported to the slurry storage tank for storage.

[0032] The combustible garbage generated in the papermaking production is dried and screened by the drying equipment using the residual heat of the boiler flue gas, and then crushed and mixed with coal powder to make mixed coal powder with a particle size of 0-10mm. The pulverized coal and mixed pulverized coal are sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com