Automatic test system for cold test of boiler and test method thereof

An automatic test system and cold-state test technology, applied in the analysis of materials, lighting and heating equipment, control of combustion, etc., can solve the problems of inability to ensure the stability of the instrument and the correct angle, increase the power consumption of the fan, and increase the test time, etc., to achieve Fast data processing, high work stability, and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

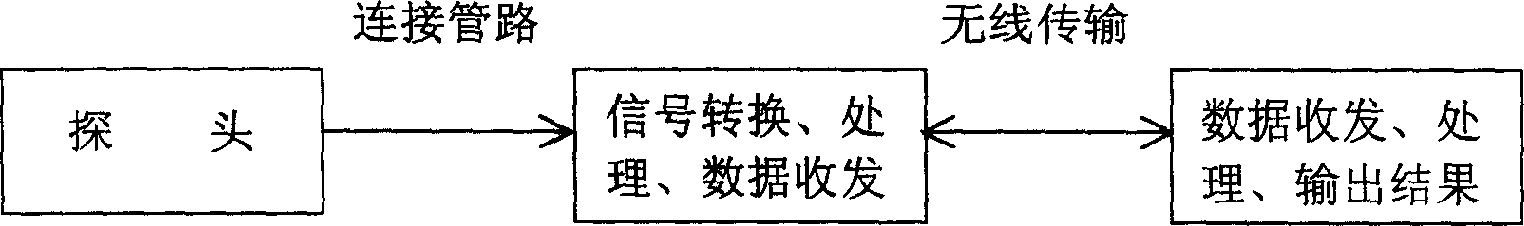

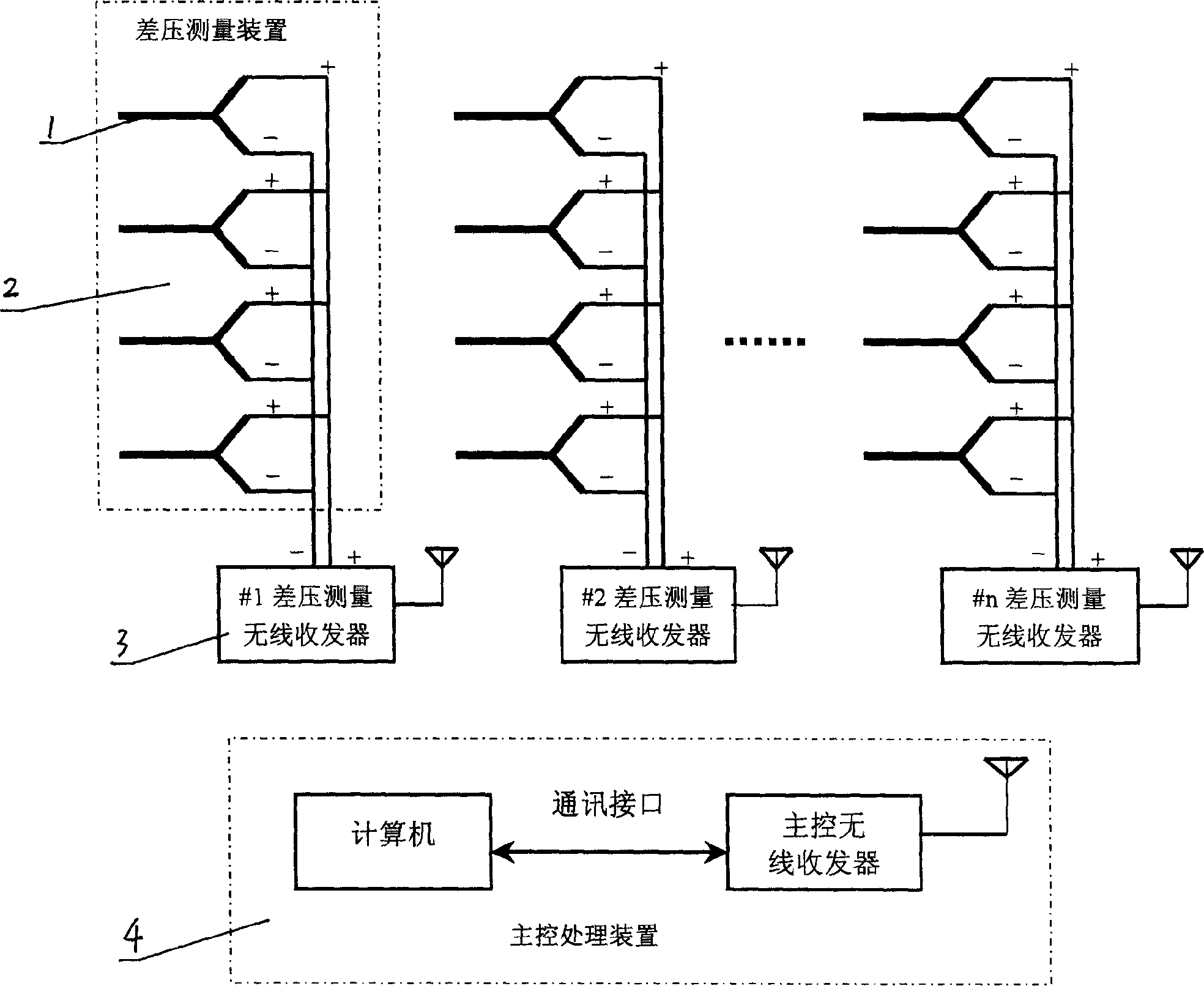

[0027] refer to figure 2 , the automatic test system of the present invention consists of a measuring probe (1), a differential pressure measuring device (2) composed of a connecting pipeline and a multi-way joint, a differential pressure wireless transceiver (3), and a main control processing device (4) to form the entire test system.

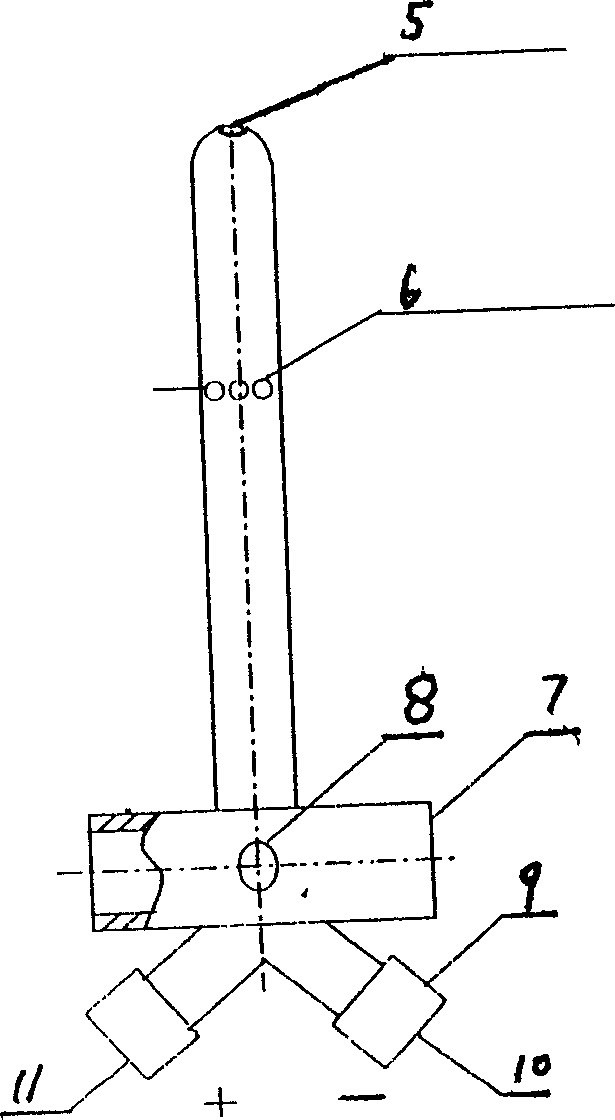

[0028] refer to Figure 5 , The differential pressure measurement device includes: wind speed measurement probe, pressure transmission pipeline, multi-way joint.

[0029] refer to image 3 and Figure 4 The wind speed measurement probe is based on the working principle of the Pitot tube to measure the fluid dynamic pressure. It is designed according to the structural needs of the automatic measurement device in the furnace. Generally, 4 probes are used for each nozzle, and the head of each probe has a full-pressure pressure-sensitive hole. (5), there is a static pressure sensing hole on the surface of the side cylinder (6), the geometric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com