Supporting type labyrinth barrage

A supporting and labyrinth technology, which is applied in barrage/weir, water conservancy projects, sea area projects, etc., can solve the problems of large project investment, section size and reinforcement amount increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

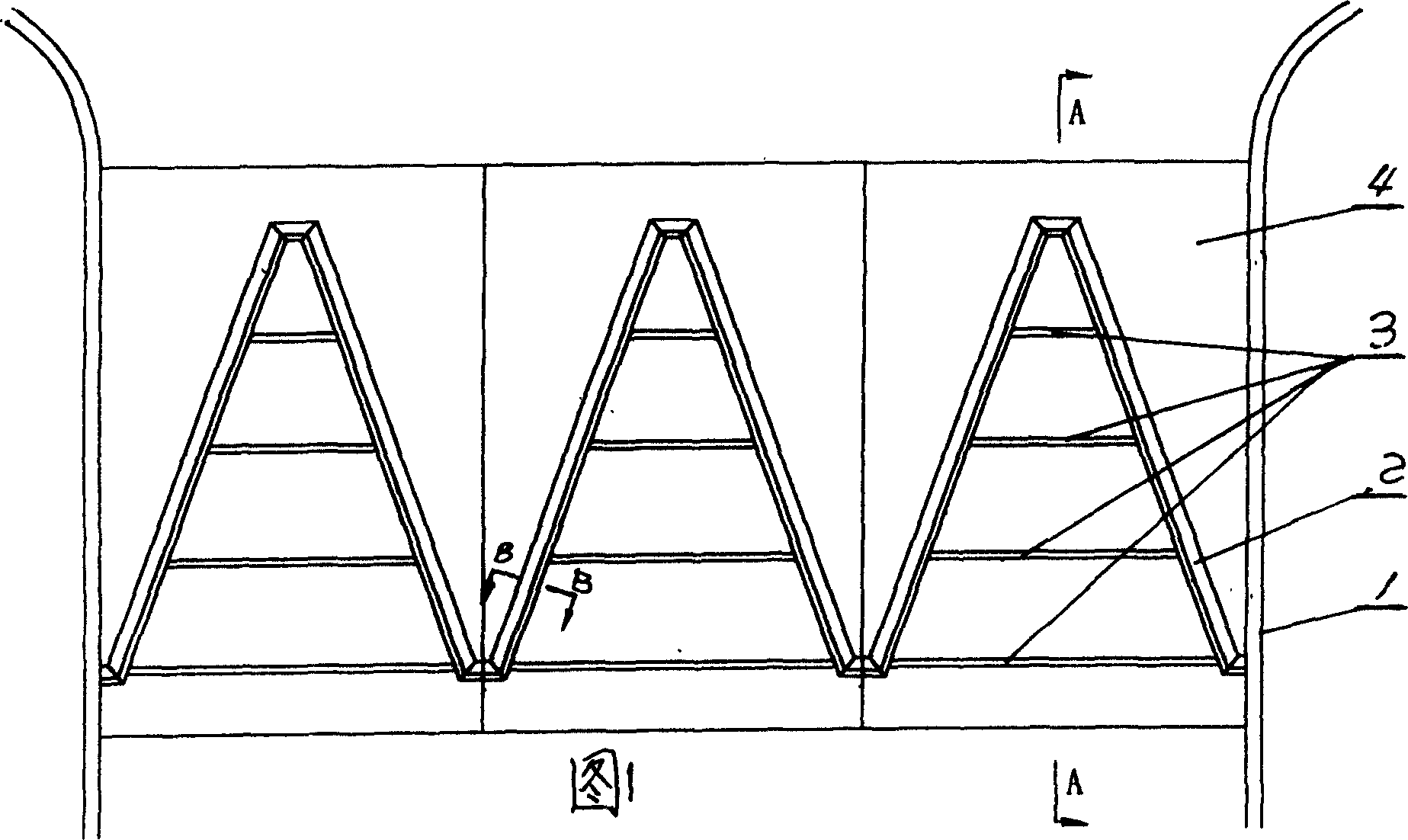

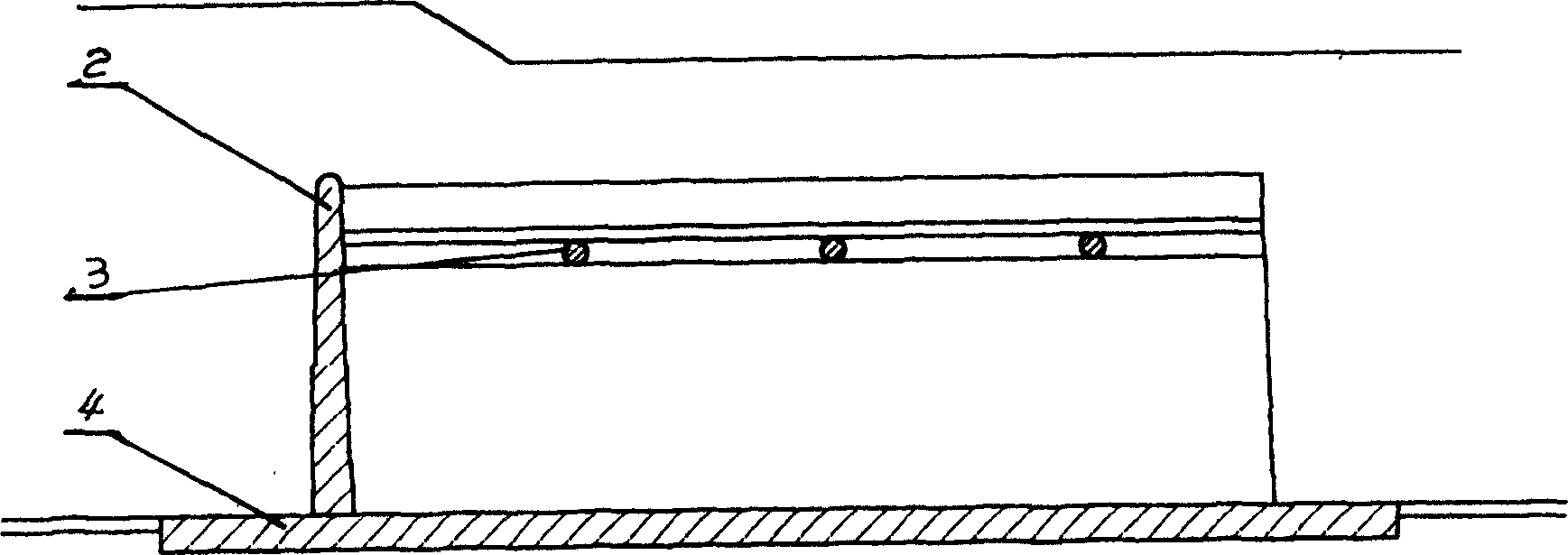

[0006] The supported labyrinth weir of the present invention comprises that a concrete bottom plate 4 is provided on the riverbed in the diversion wall 1, and the labyrinth weir wall 2 is fixedly connected on the bottom plate 4, and four walls are evenly arranged between the outer sides of the two opposite weir walls. A horizontal support beam 3, the reinforcement at both ends of the support beam is connected with the hidden beam reinforcement at the upper part of the weir wall body, and the weir wall and the support beam form an integral structure. When the outermost horizontal support beam was longer, the span of the beam was larger at this moment, and the horizontal support could be changed into two oblique support beams 5, and the two ends of the support beam were connected with the concealed beam and the base plate of the weir wall respectively. The support beams can be prefabricated in the prefabrication plant, and then cast in one piece with the weir wall on site. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com