Device for detecting difference in warp tension of a loom

A difference detection and warp technology, applied in the field of detection devices, can solve problems such as inability to measure displacement correctly, inability to measure accurate distance, and rocker structure cannot measure with high precision, so as to simplify the calculation and processing of detection signals and reduce parts The effect of the number of pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

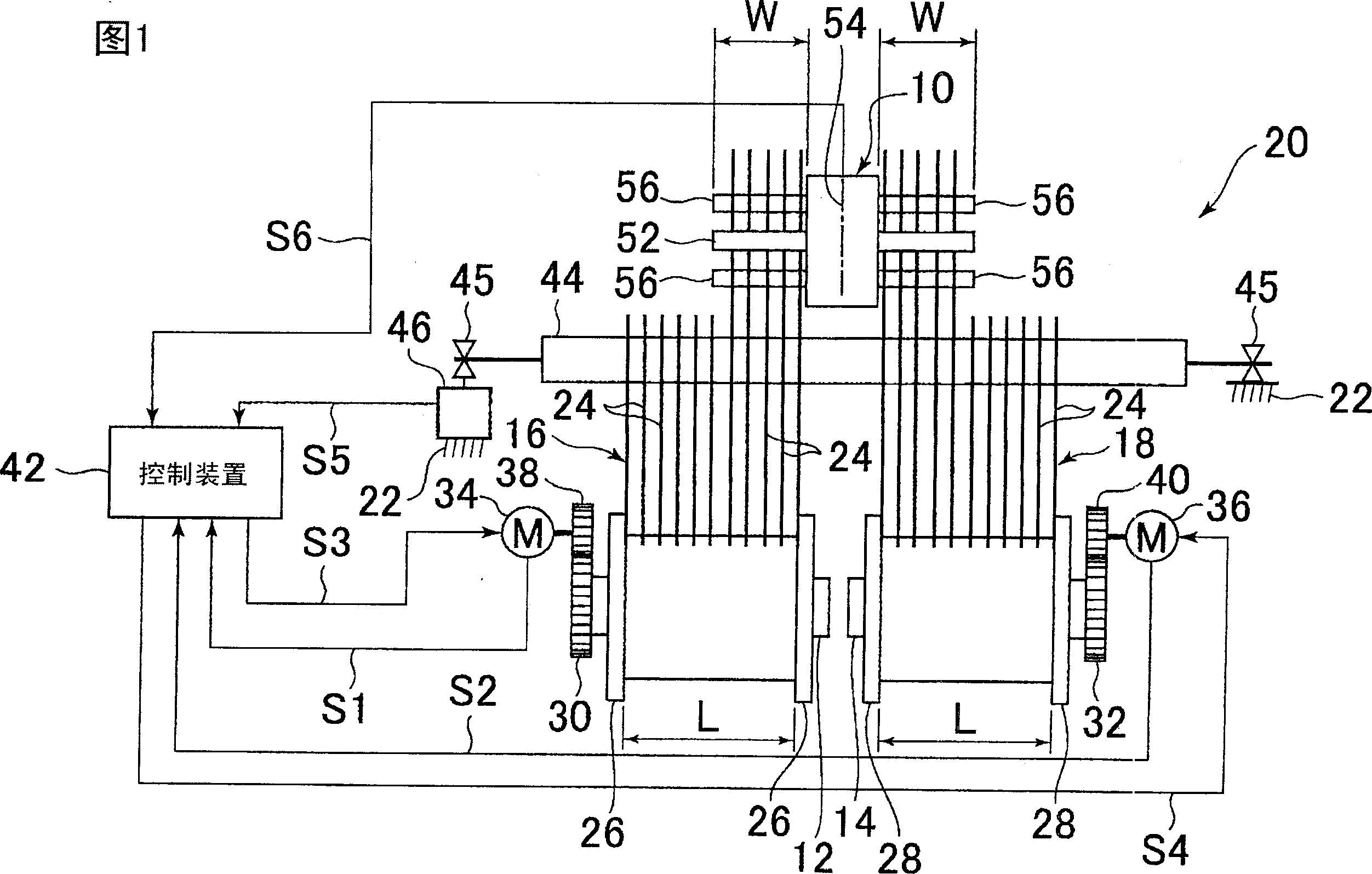

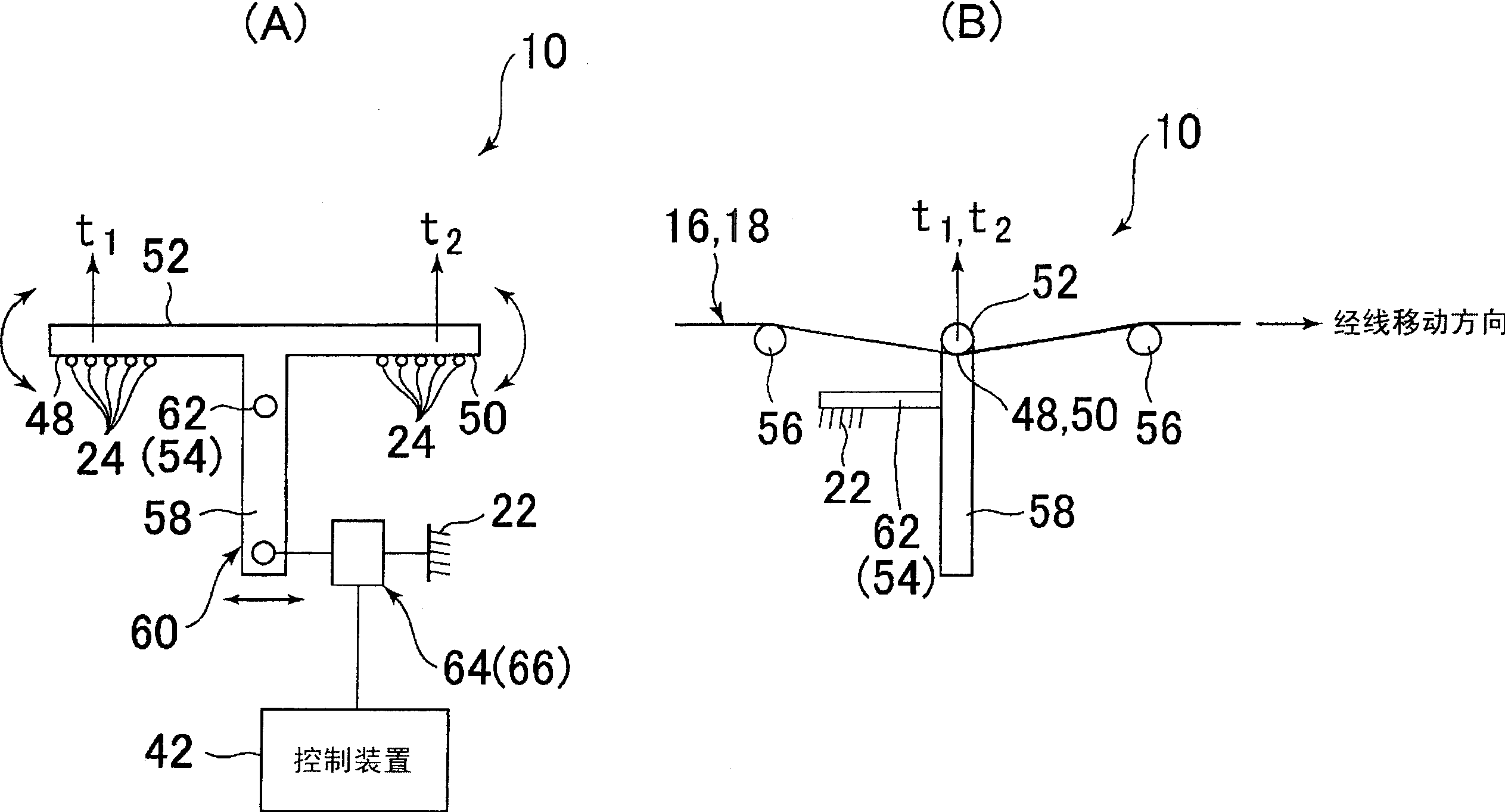

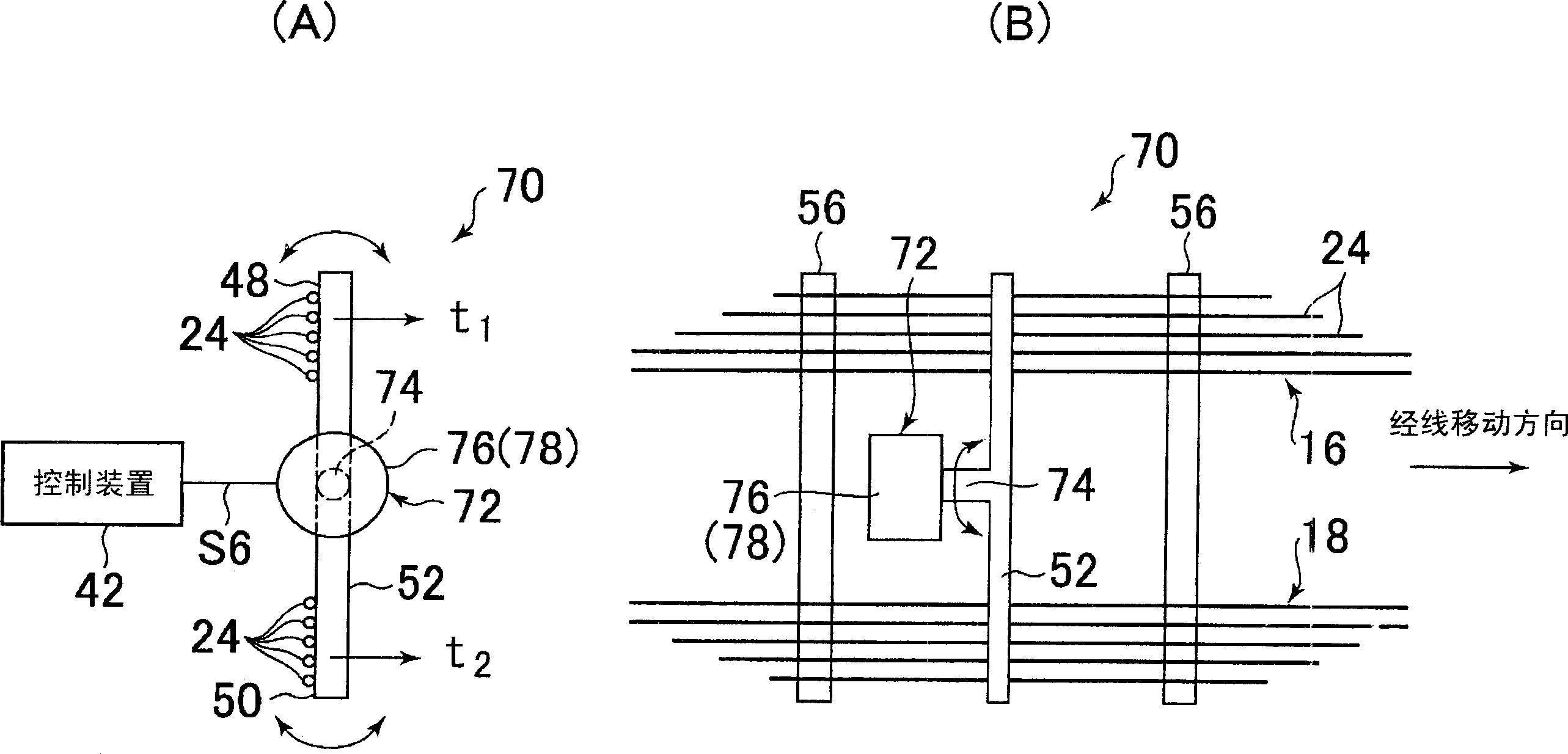

[0026] Referring to Fig. 1, warp yarn tension difference detecting device 10 detects the warp yarn tension difference of two warp yarn plane bundles 16 and 18 sent out from two warp yarn reels 12 and 14 along the adjacent weft insertion direction.

[0027] The warp yarn reels 12 and 14 are arranged on the frame 22 of the loom 20 at a certain interval along the weft insertion direction and make their rotation axes coincide. Warp yarn reels 12 and 14 each wind several warp yarns 24, and these warp yarns 24 are sent out along the adjacent weft insertion direction in the form of warp yarn plane bundles 16 and 18 arranged in parallel in a plane bundle shape. The warp roll width L of the warp reels 12 and 14 is the same.

[0028] The warp reels 12 and 14 are provided with detachable warp beam flanges 26 and 28 at both ends thereof, and detachable warp reel gears 30 and 32 are attached to the opposite sides.

[0029] Warp yarn reel gears 30 and 32 are respectively engaged with gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com