Motor driving system

A drive system, motor technology, applied in motor generator/starter, starter of a single polyphase induction motor, control system, etc., can solve the problems of rising cost and large-scale, and achieve the effect of reducing output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

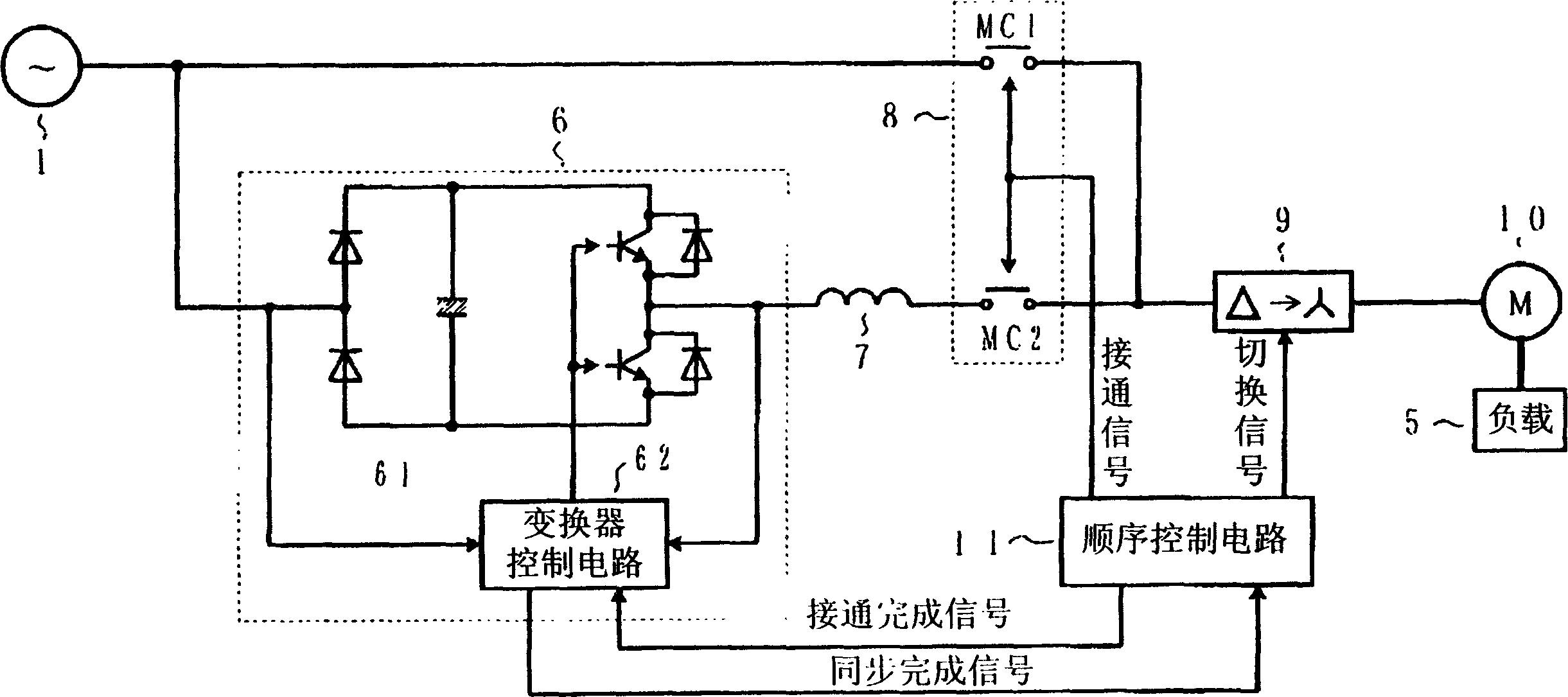

[0019] figure 1 is a circuit configuration diagram showing the motor drive system of Embodiment 1 of the present invention, and image 3 Parts with the same function in the conventional example circuit are marked with the same symbols.

[0020] That is, in figure 1 In the circuit structure of the shown embodiment, in addition to the commercial power supply 1 and the load 5, it is equipped with: a converter main circuit 61 and a converter control circuit 62, which can be controlled by the converter control circuit 62. The output phase is connected to the commercial power supply 1 AC voltage variable voltage variable frequency (VVVF) converter 6, AC reactor 7, main switch circuit 8 composed of electromagnetic contactors MC1 and MC2, delta-star (Δ-Y) switch 9 , The induction motor 10 and the sequence control circuit 11 for making the primary winding in an open circuit.

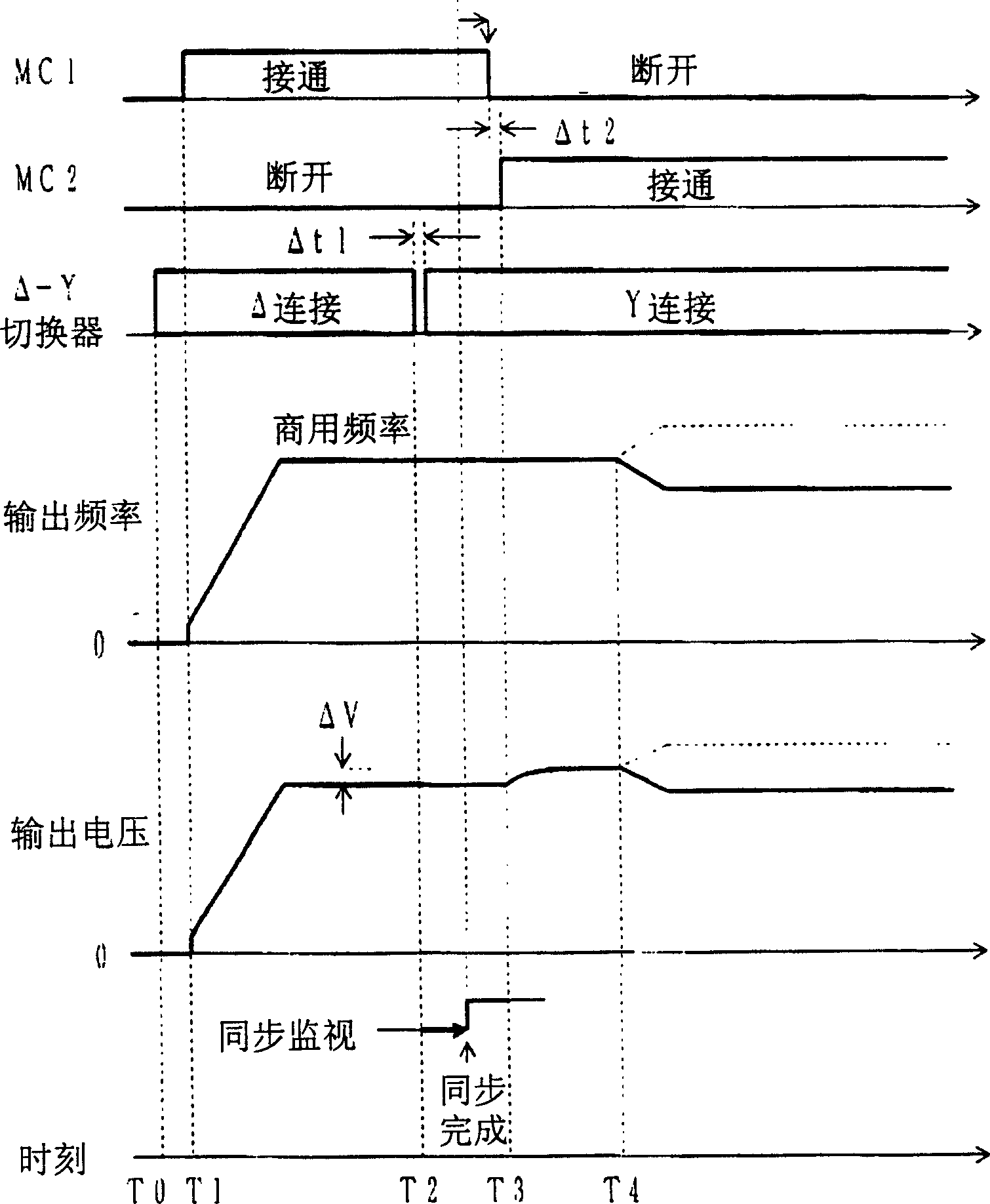

[0021] Below, refer to figure 2 The waveform diagram shown to illustrate figure 1 Action of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com