Frequency conversion digital compressor

A compressor and frequency conversion motor technology, applied in the field of gas compressors, can solve the problems of reduced reliability, waste of resources, waste of energy, etc., and achieve the effect of reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

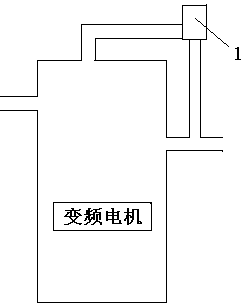

[0019] Inverter digital compressor such as figure 1 , which is a scroll compressor, including a PWM valve and a motor, and the motor is a variable frequency motor.

[0020] In traditional digital compressors, the operating frequency of the motor is not variable, so under low load, the operating frequency of the motor is higher, and a lower capacity output is achieved with a lower ratio of valve closing load time. Compared with digital compressors with frequency conversion, under low load, the PWM valve is triggered to adjust the output capacity, and the motor can run at a lower frequency. Therefore, the proportion of time for valve closing load is higher than that of traditional digital compressors, and the time for idling is higher than that of traditional digital compressors. The ratio is correspondingly lower, so losses are lower than in conventional digital compressors. Inverter digital compressor, under low load, the motor can be fixed in frequency, and the output capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com