Float sealing structure for water-saving automatic washer

A fully automatic washing machine and sealing structure technology, which is applied to the sealing of engines, other washing machines, engine components, etc., can solve the problems of short service life of the seal 10, increase in cost, easy noise generated by the seal, and achieve easy manufacturing and installation. Reduced manufacturing cost and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

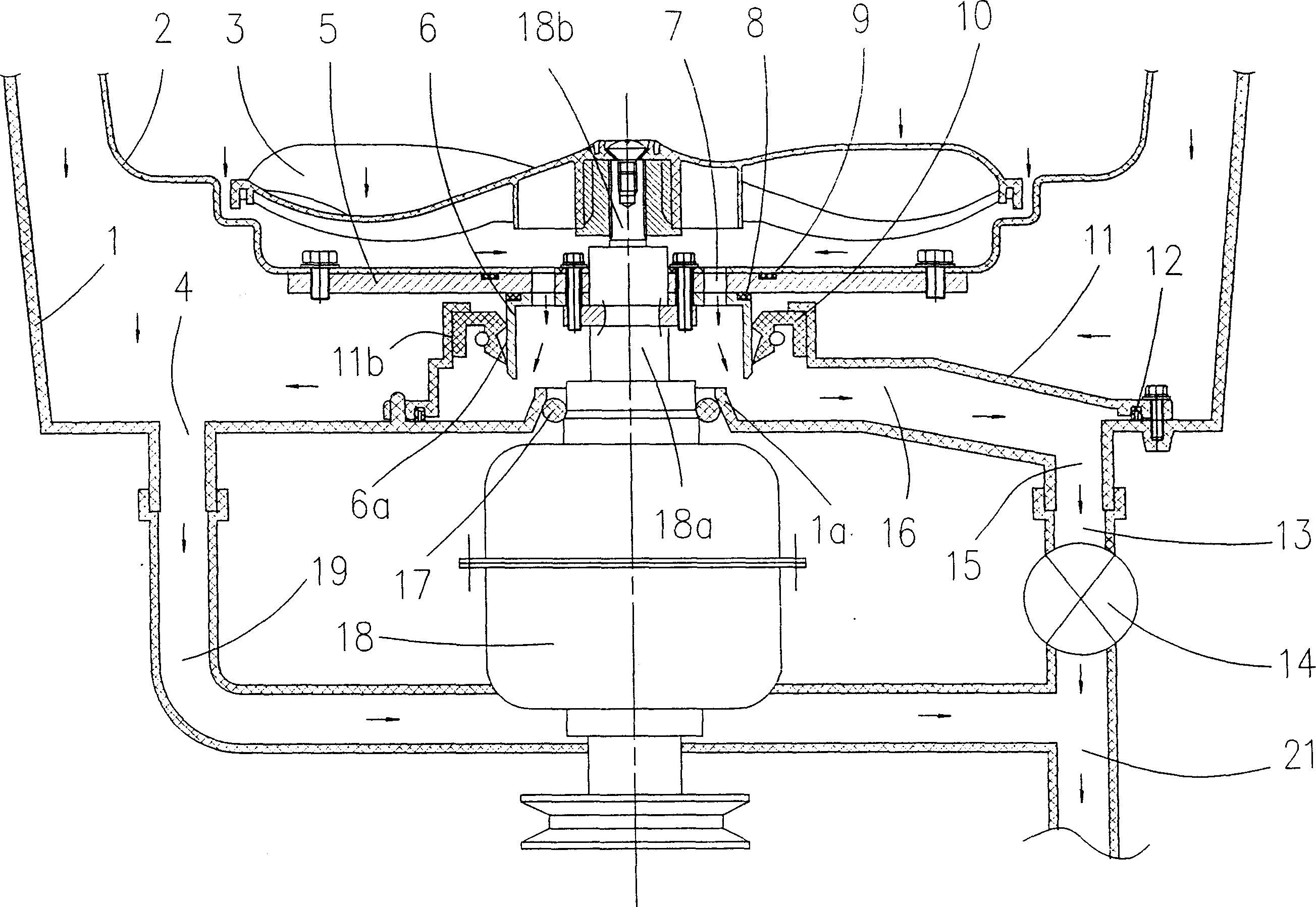

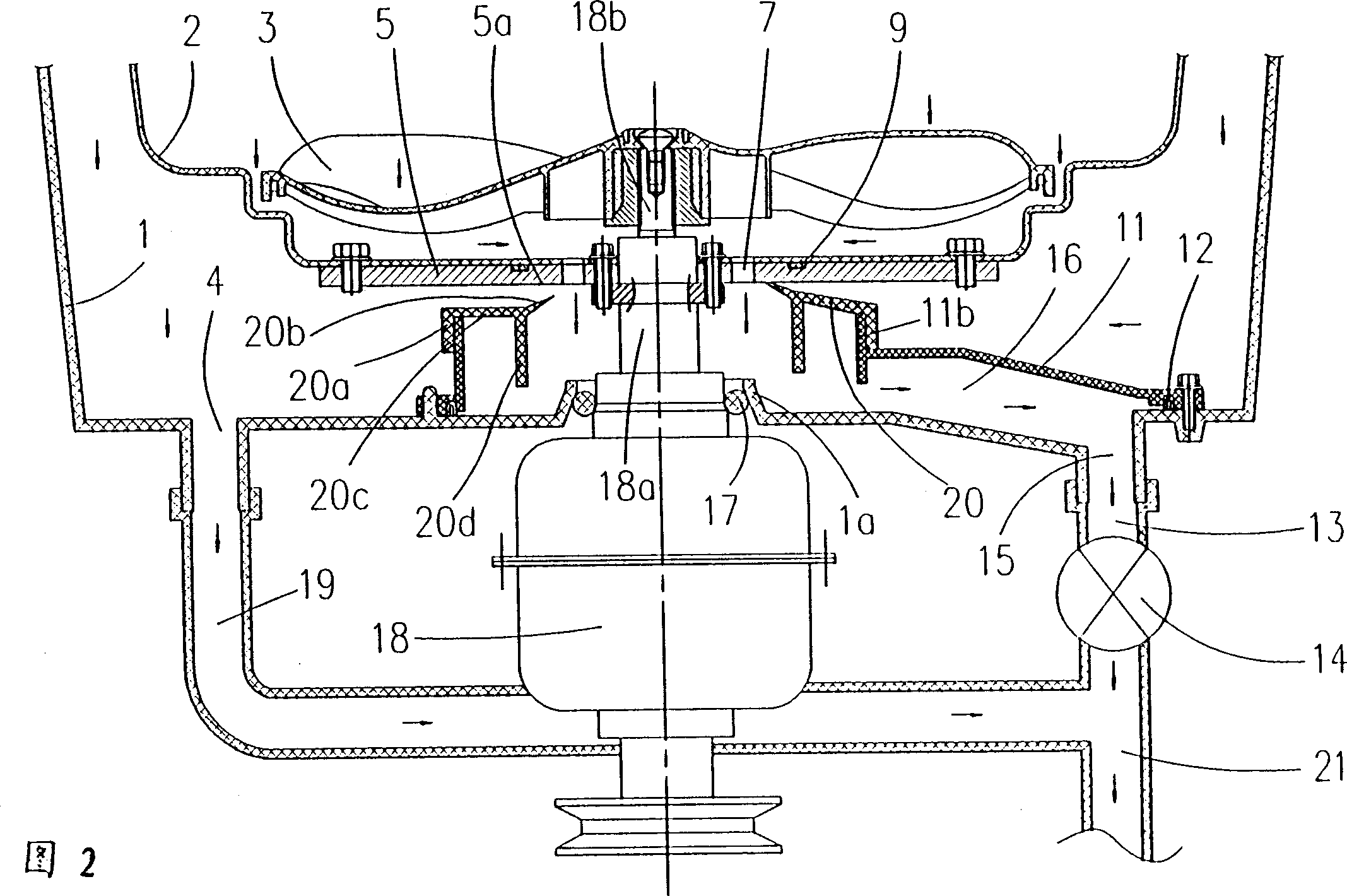

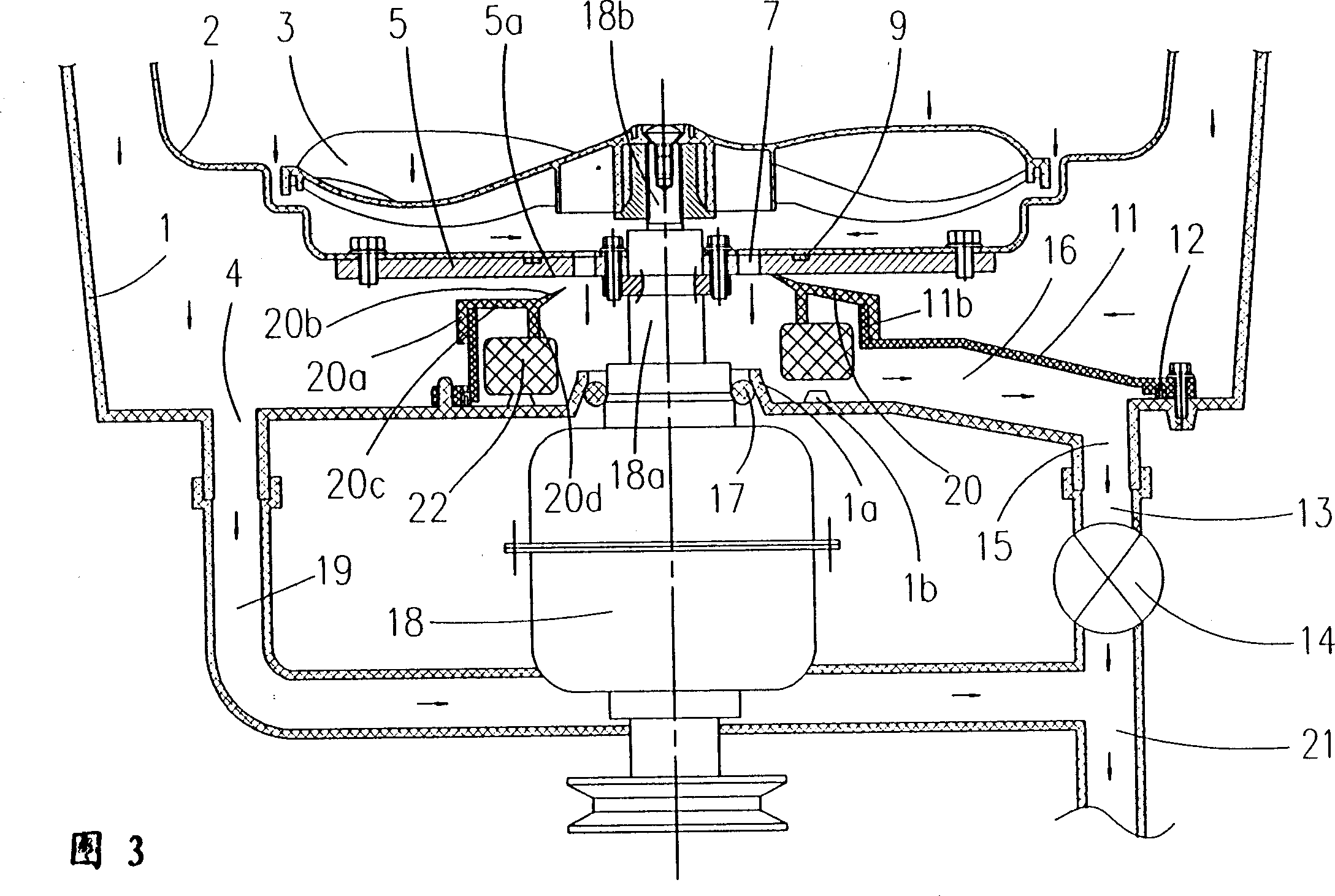

[0045] The water-saving fully automatic washing machine floating body type sealing structure shown in Fig. 2 is the first embodiment of the present invention. The seals shown in the figure are in two states, the seal on the left is in a separated state (dehydration or anhydrous state in the inner barrel), and the seal on the right is in a combined state. At this time, the seal seals the drainage chamber 16 (washing or water storage in the inner barrel) ). The sealing structure includes a sealing cover 11 fixed inside the bottom of the outer tub 1, a tray 5 fixed at the bottom of the inner tub 2, a drainage chamber 16 surrounded by the outer tub 1, the sealing cover 11 and the tray 5, and a sealing member, wherein the tray 5 It can rotate together with the inner barrel 2, that is, it moves relative to the sealing cover 11, and the annular surface other than the evenly distributed drainage holes (7) on the tray is the tray sealing surface; the seal is made of rubber material and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com