Hand-held drilling and/or hammering device with dust collecting element

A dust collection and tool technology, applied in the field of hand-held drilling and/or hammering tools, dust collection units, which can solve the problems of reduced motor rotation speed, motor speed can not choose the best speed of the fan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

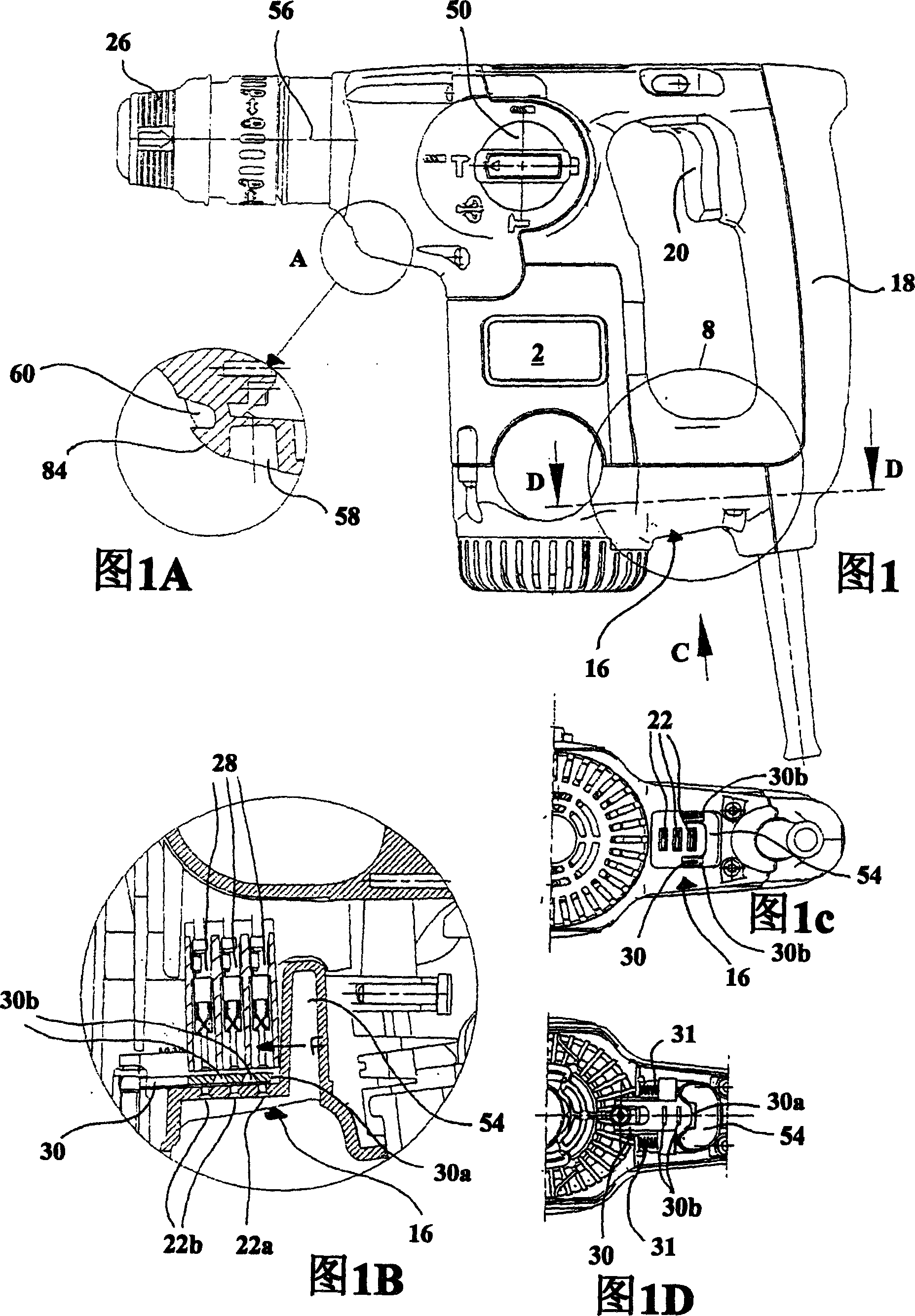

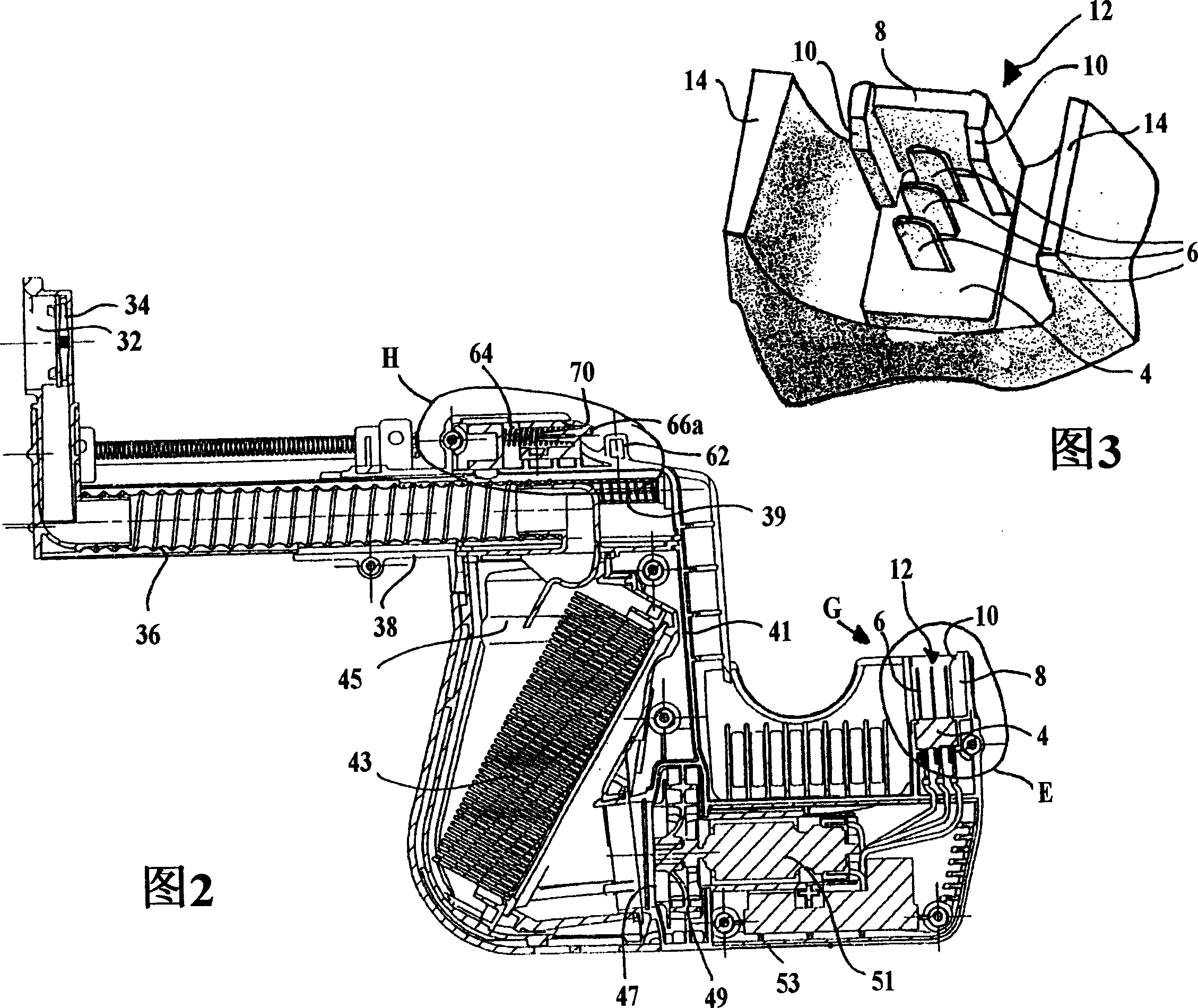

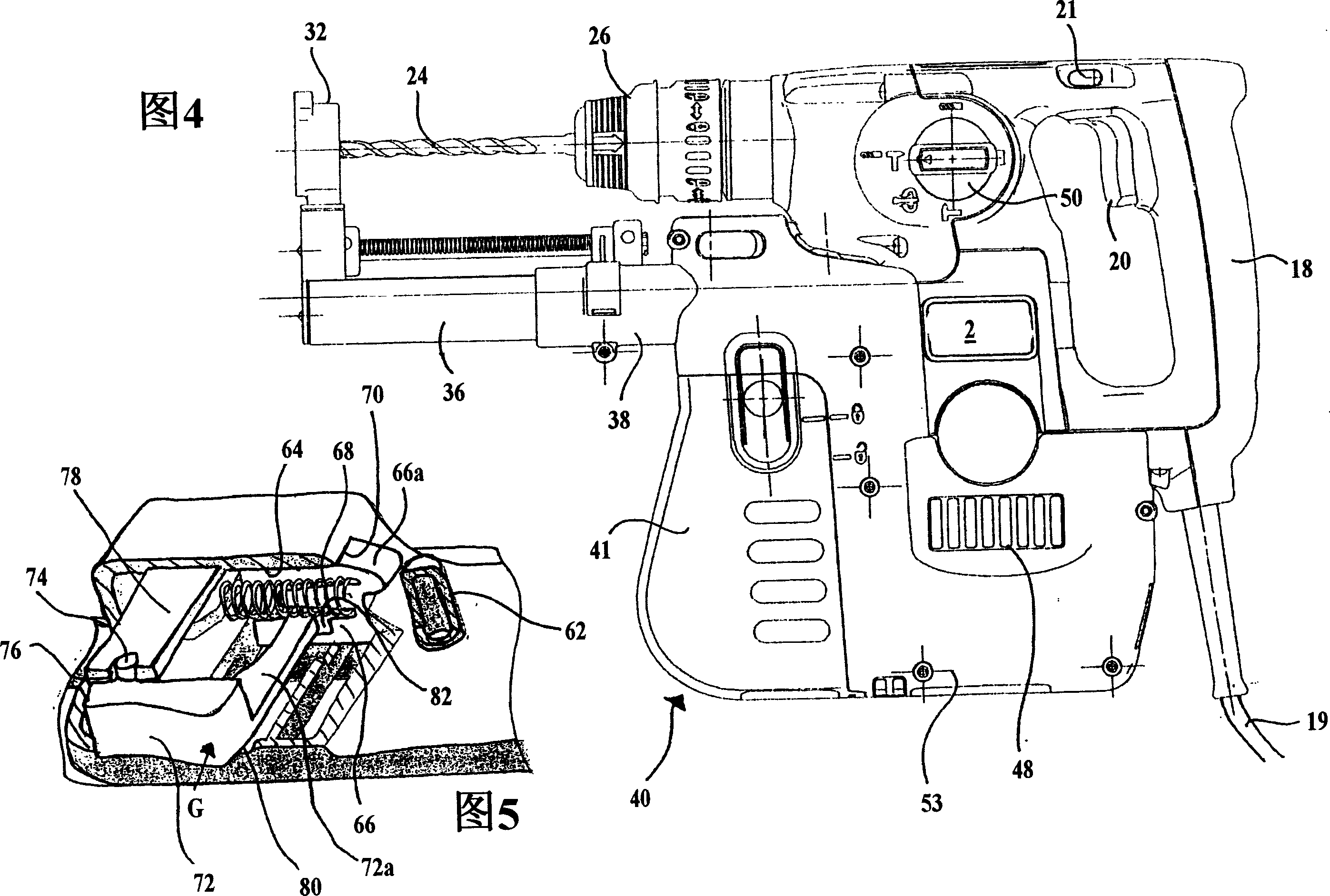

[0033] The hand hammer shown in FIGS. 1 and 4 is known to have a housing which contains a motor housing part ( 2 ) in which the electric motor ( 3 ) of the hammer is housed. The tool holder (26) is positioned at the front end of the electric hammer shaft. A tool or drill (24) may be non-rotatably and releasably secured in the tool holder to allow limited reciprocating movement of the tool or drill relative to the tool holder. The hammer has a back handle (18) with an on / off trigger (20) for operating a switch (23) to turn on power to the motor. The motor (3) of the electric hammer selectively drives a spindle drive mechanism to rotationally drive the shaft of the electric hammer, thereby rotationally driving the tool holder (26) and the tool or drill bit (24) mounted thereon, which is known in the art It is well known. Additionally, the hammer motor selectively drives an air cushion hammering mechanism to repeatedly strike the tool or bit (24), as is well known in the art. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com