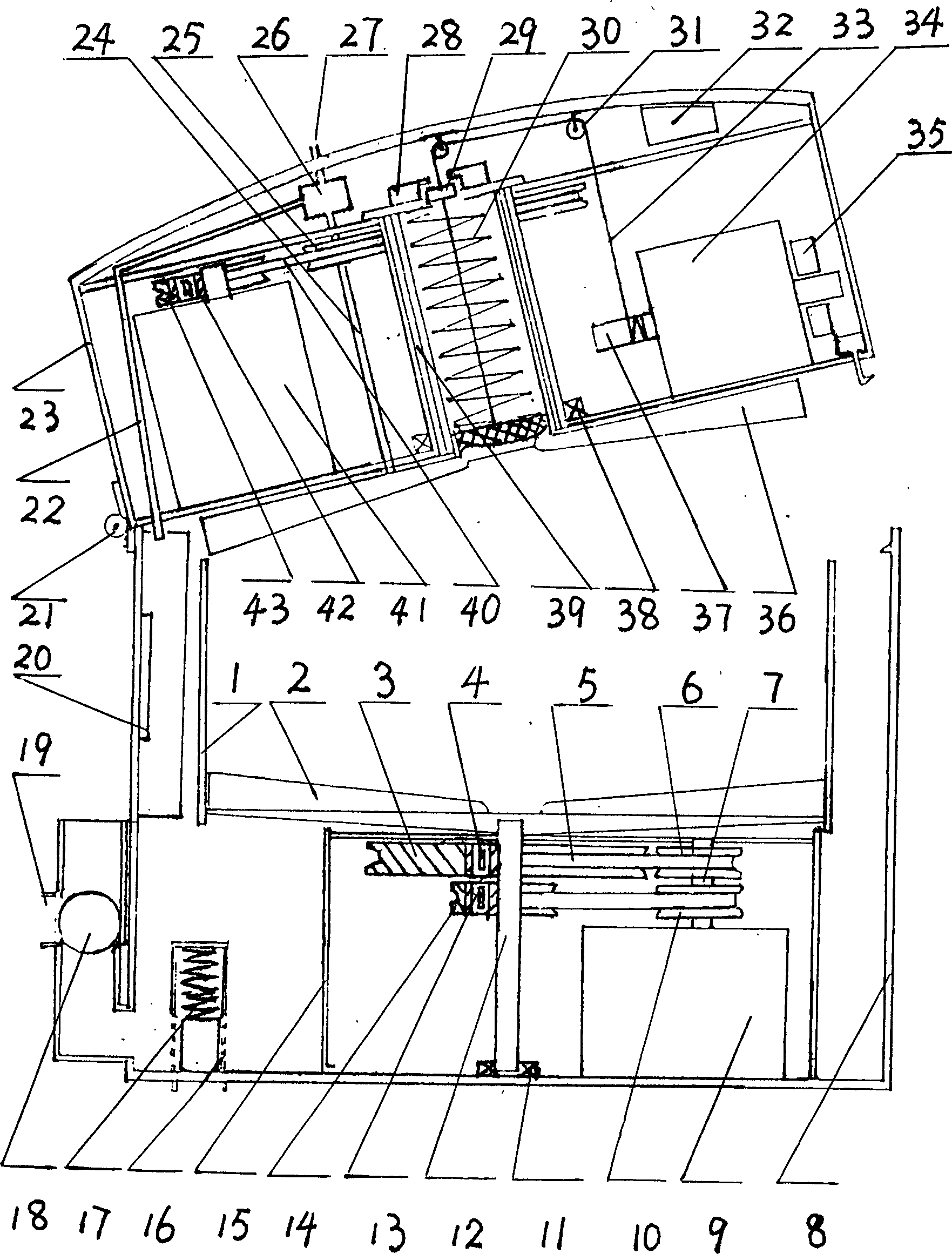

Kneading type washing machine

A washing machine and rubbing technology, applied in the field of household washing machines, can solve the problems of poor cleaning degree, low degree of automation, and difficulty in adapting, and achieve the effects of reducing production volume, improving cleaning degree and enhancing frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

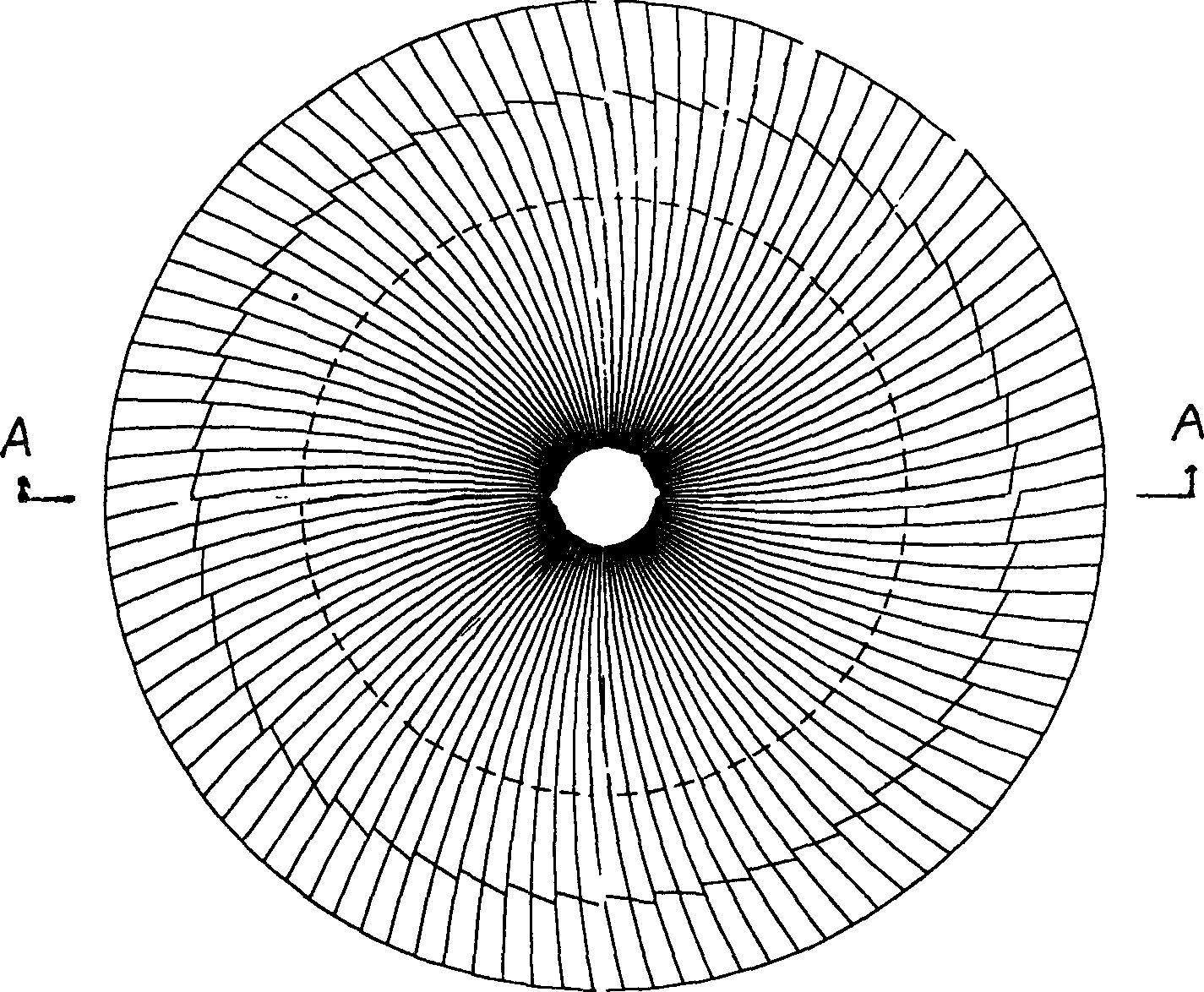

[0052] Embodiment 2, its structure is basically the same as the above-mentioned embodiment, the difference is: 1, the pulsator in this embodiment, the included angle of any radial line from the center on its working surface and the horizontal plane passing through the center is 5 degrees; 2, the pulsator in this embodiment is evenly distributed with arc-shaped ribs; 3, the inner diameter of the upper part of the washing tub in this embodiment increases with its height, and there are some flow guide ribs on its inner wall ; 4, the drain solenoid valve is omitted in this embodiment; 5, the output shaft of the lower washing motor in this embodiment is equipped with two internal tooth ratchet type overrunning clutches whose no-load direction is opposite to each other, and the outer rings of the two overrunning clutches They are respectively connected to two pulleys (washing pulleys and dehydration pulleys) with different diameters fixedly installed on the washing shaft through two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com