Resin composition for optical part and optical part

A technology of resin composition and optical components, applied in the directions of optical elements, optics, instruments, etc., can solve the problems of large optical axis deviation, disc recording and reproduction obstacles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

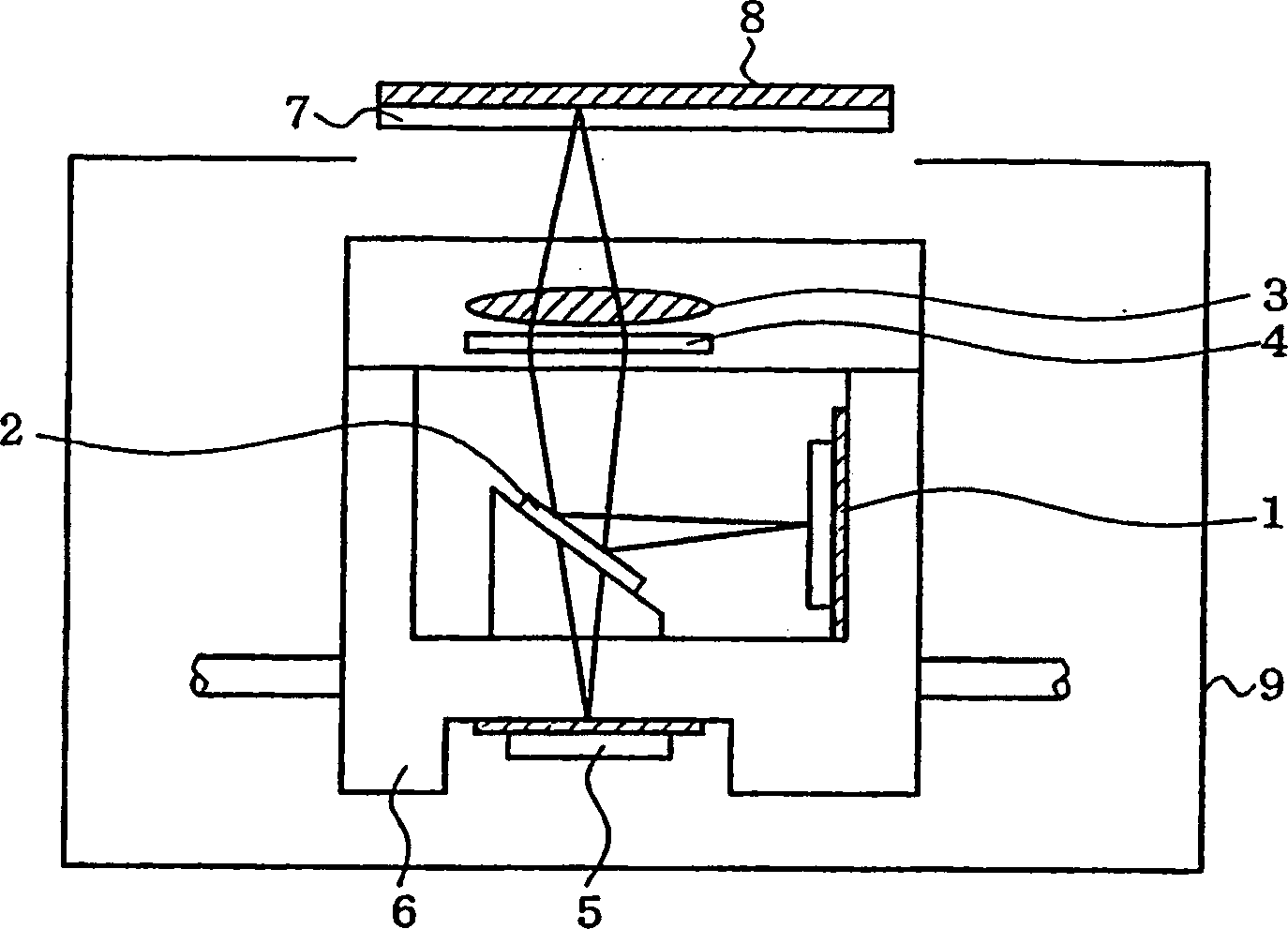

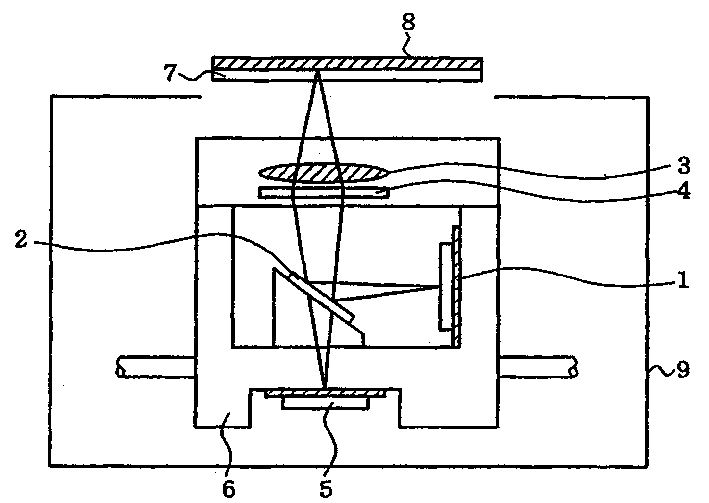

Image

Examples

Embodiment 1~2、 comparative example 1~2

[0045] [1] Materials used as each component

[0046] [A] Ingredients

[0047] [a1] Syndiotactic polystyrene [manufactured by Idemitsu Petrochemical Co., Ltd.: 130ZC]

[0048] 1) Melt index [300°C, 11.77N]: 13g / 10min

[0049] 2) Weight average molecular weight: 300000

[0050] 3) Molecular weight distribution: 2.5

[0051] 4) Melting peak temperature: 271°C

[0052] 5) Glass transition temperature: 99°C

[0053] 6) Density [25°C, atmospheric pressure]: 1.04

[0054] [a2] Polyphenylene sulfide [manufactured by Tosoh Corporation: #160]

[0055] 1) Cross-linked type

[0056] 2) Melt viscosity [300°C, 1000 seconds -1 ]: 1500 Poise

[0057] 3) Density [25°C, atmospheric pressure]: 1.35

[0058] (B) Ingredients

[0059] (b1) Glass fiber [manufactured by Asahi Glass Fiber Co., Ltd.: JAFT591]

[0060] 1) Fiber diameter: 10μm

[0061] 2) Density [25°C, atmospheric pressure]: 2.55

[0062] (b2) Calcium carbonate [manufactured by Shiraishi Industry Co., Ltd.: ホワイトン P30]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt viscosity | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com