Plamsa display panel display device and its driving method

A plasma and display device technology, applied in static indicators, televisions, instruments, etc., can solve the problems of low withstand voltage limit, write pulse fluctuations of discharge cells, and rising costs, achieve good image display, avoid circuit heating, Avoid cost-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1-1. Configuration of PDP display device (panel drive unit)

[0054] In the PDP display device of the first embodiment, the PDP unit 10 is substantially the same as the above-mentioned conventional structure, but the structure of the panel driving unit 40 connected thereto has a different feature. Next, the panel driving unit 40 will be described.

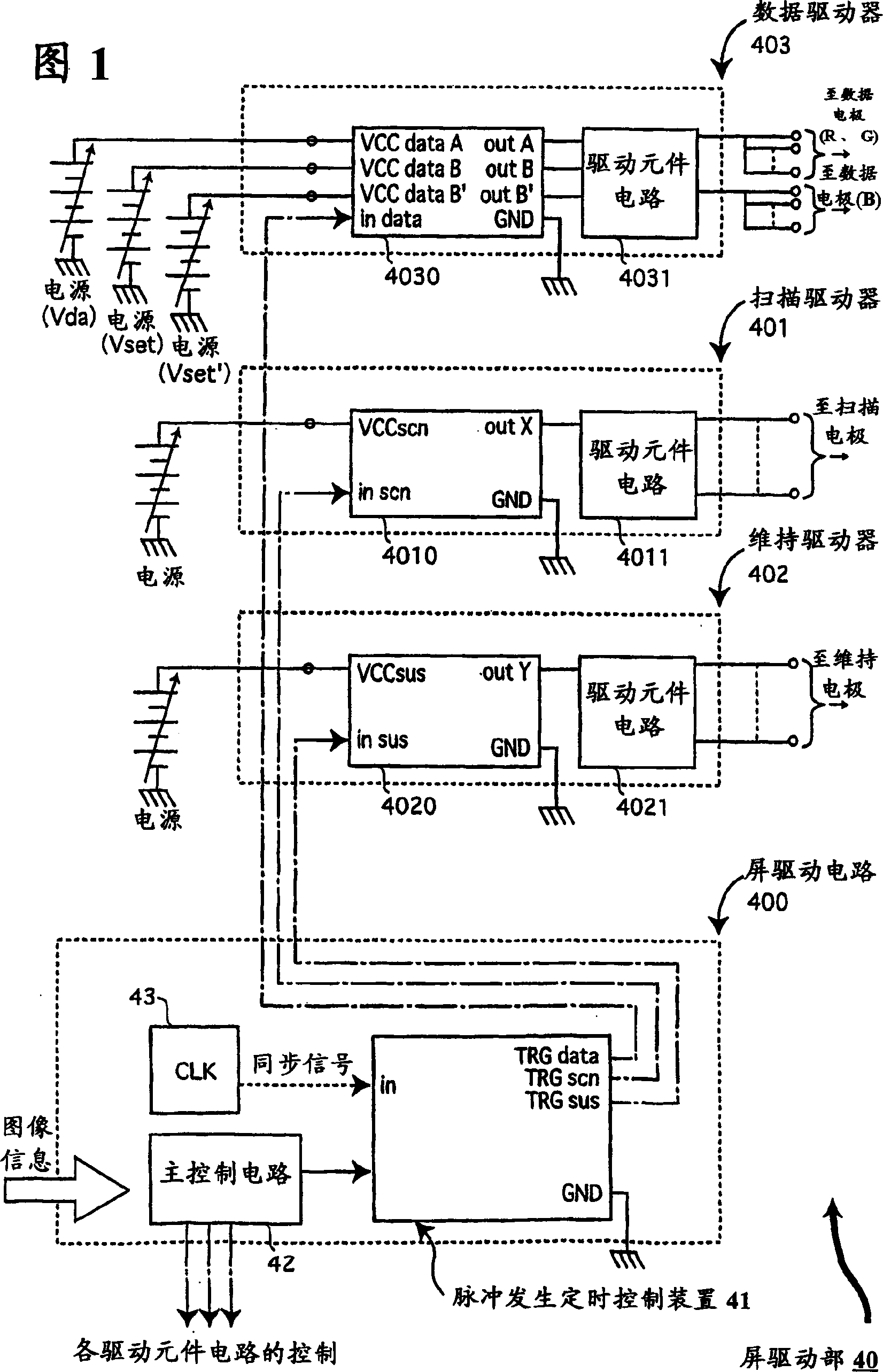

[0055] FIG. 1 is a diagram showing the peripheral configuration of a panel driving unit in the first embodiment.

[0056] The panel driving section 40 shown in FIG. 1 is composed of (1) a data driver 403 connected to each data electrode 32, (2) a scan driver 401 connected to each scan electrode (X electrode) 25, (3) and each sustain electrode (Y electrode). electrode) 24 connected to the sustain driver 402 and (4) the panel drive circuit 400 that controls the operation of these drivers 401 to 403 and the like.

[0057] A sustain pulse generation timing control device 41 (hereinafter referred to as "pulse control device 41"...

Embodiment 2

[0148] 2-1. PDP display device in Embodiment 2

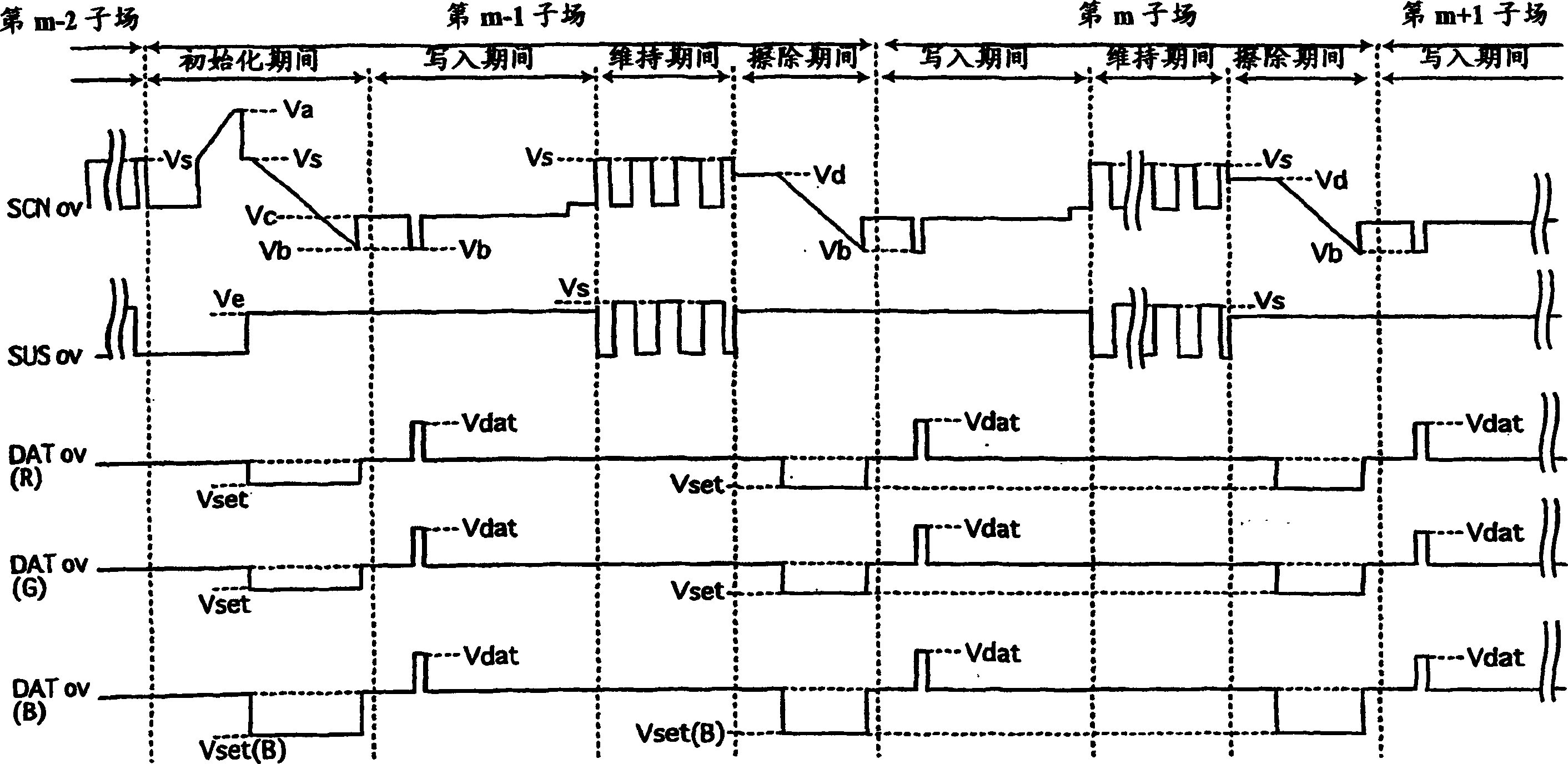

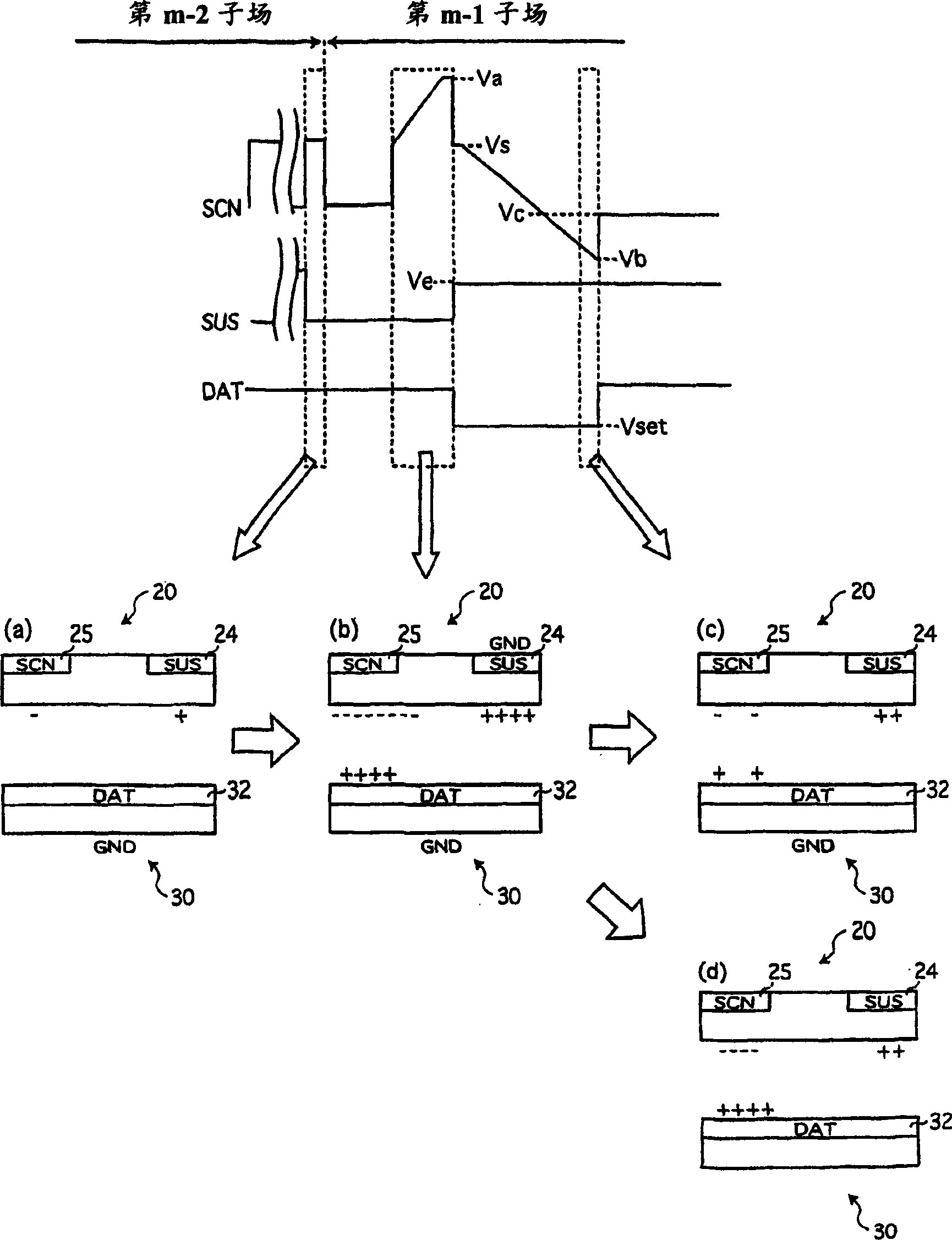

[0149] The device structure of Embodiment 2 of the present invention is substantially the same as that of Embodiment 1, so repeated descriptions are omitted here. The present embodiment 2 is characterized by a driving waveform process.

[0150] That is, the second embodiment is characterized in that in the initialization period or erasing period immediately after the application of the sustain electrode 24 to the sustain electrode 24 in the subfield is completed, the incremental voltage is applied to the scan electrode 25 and the voltage is applied to the data electrode 32 at the same time. Apply a positive polarity pulse.

[0151] 2-2. Driving process of PDP display device

[0152] The driving process of the PDP display device of the second embodiment is as follows. according to Figure 6 The driving process of the PDP display device will be described in the driving waveform timing diagram (m-1th subfield) of FIG.

[0153]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com