Field transmitting display

A field emission and display device technology, applied in image/graphic display tubes, cathode ray tubes/electron beam tubes, screen tubes, etc., can solve problems such as unstable field emission performance, uneven scale, and reduced device life, and achieve Realize large-area highly consistent uniformity, stable field emission performance, and the effect of achieving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

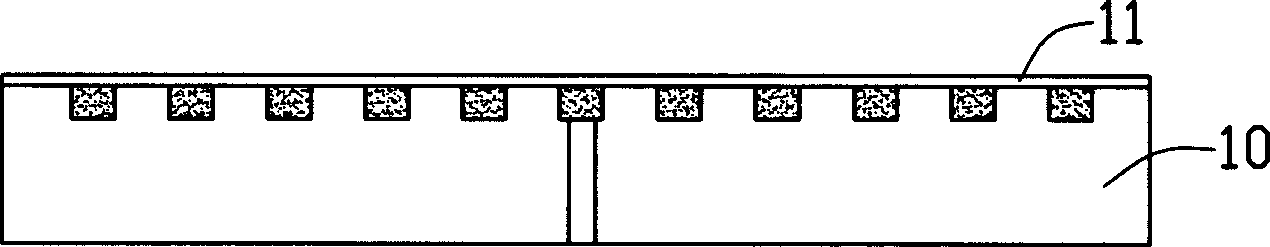

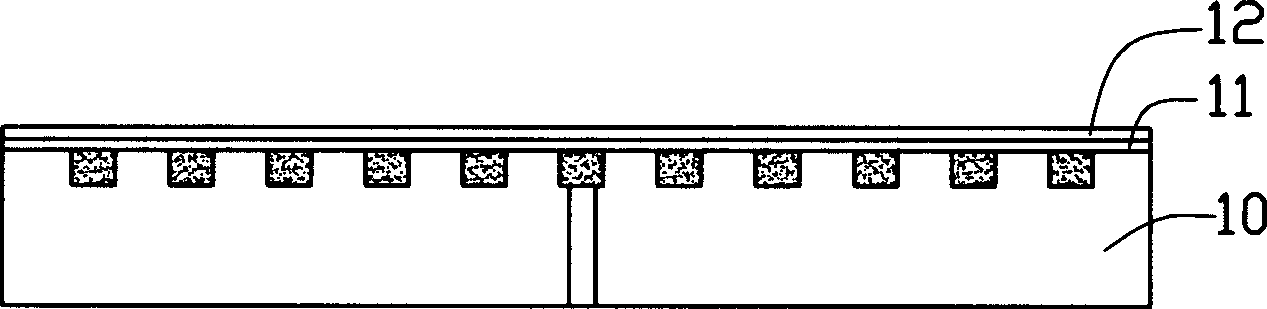

[0033] Please see first Figure 13 , a schematic structural view of the field emission display of the present invention. It includes: a cathode 17, an anode 20, a grid 19 between the cathode 17 and the anode 20, a carbon nanotube array 15 used as a field emission unit and an insulating layer 14 between the grid 19 and the cathode 17, the carbon nanotube array One end face of 15 is electrically connected to the cathode 17, and the other end face of the carbon nanotube array 15 is basically on the same plane as the end face of the insulating layer 14 close to the grid, and an insulating dielectric film is also included between the insulating layer 14 and the grid 19 11 and protective layer 12.

[0034] pass below Figure 1 to Figure 12 The manufacturing method of the field emission display of the present invention is introduced.

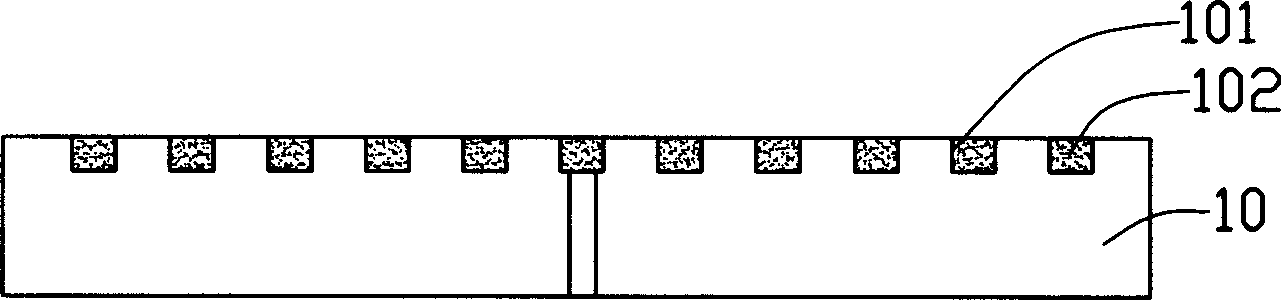

[0035] see figure 1 , firstly, a working board 10 is provided, the surface of the working board 10 may have fine grooves 101 or air holes, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com