Two stroke engine

An engine and two-stroke technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems that the demoulding is not easy, the demoulding slope is not large enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

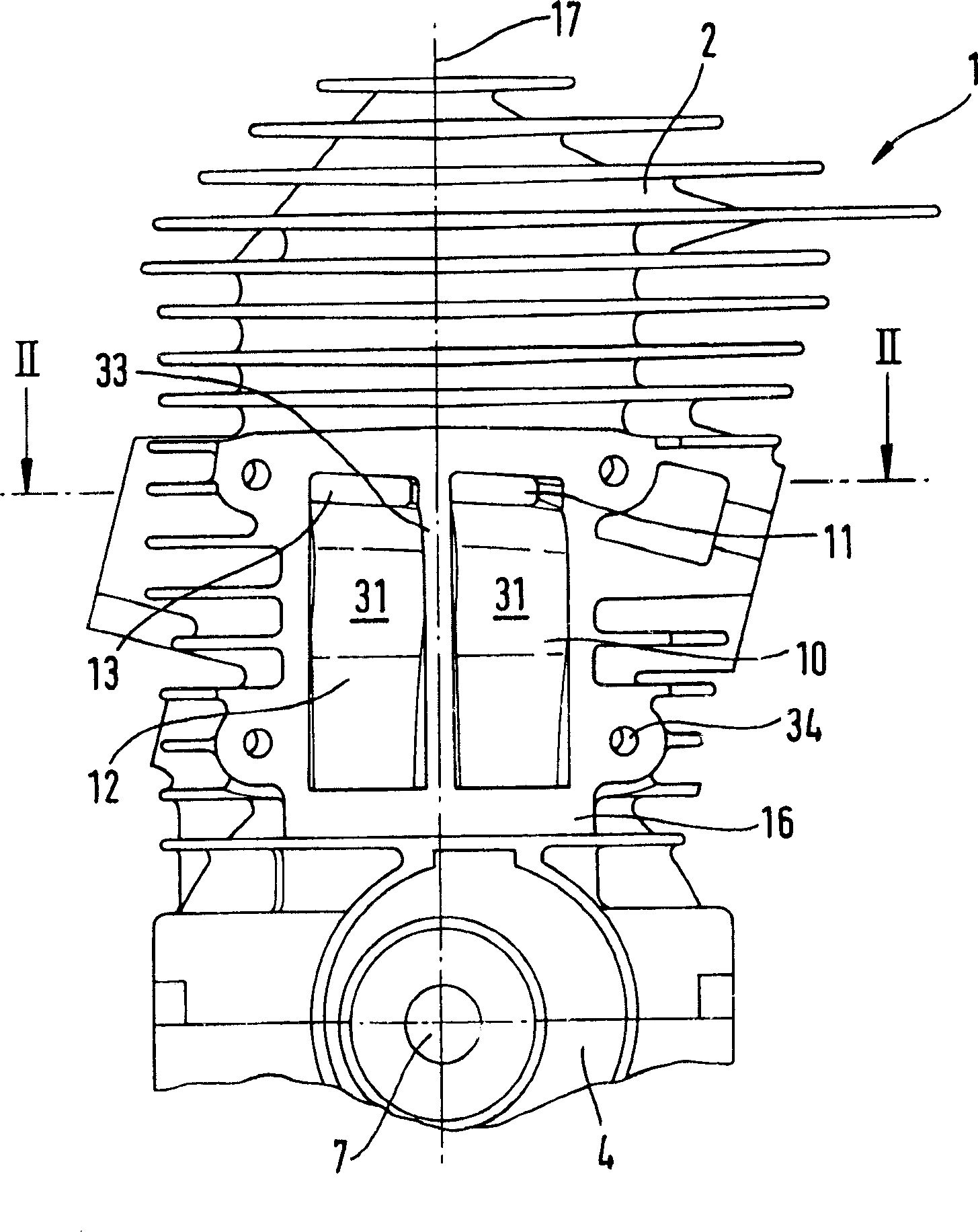

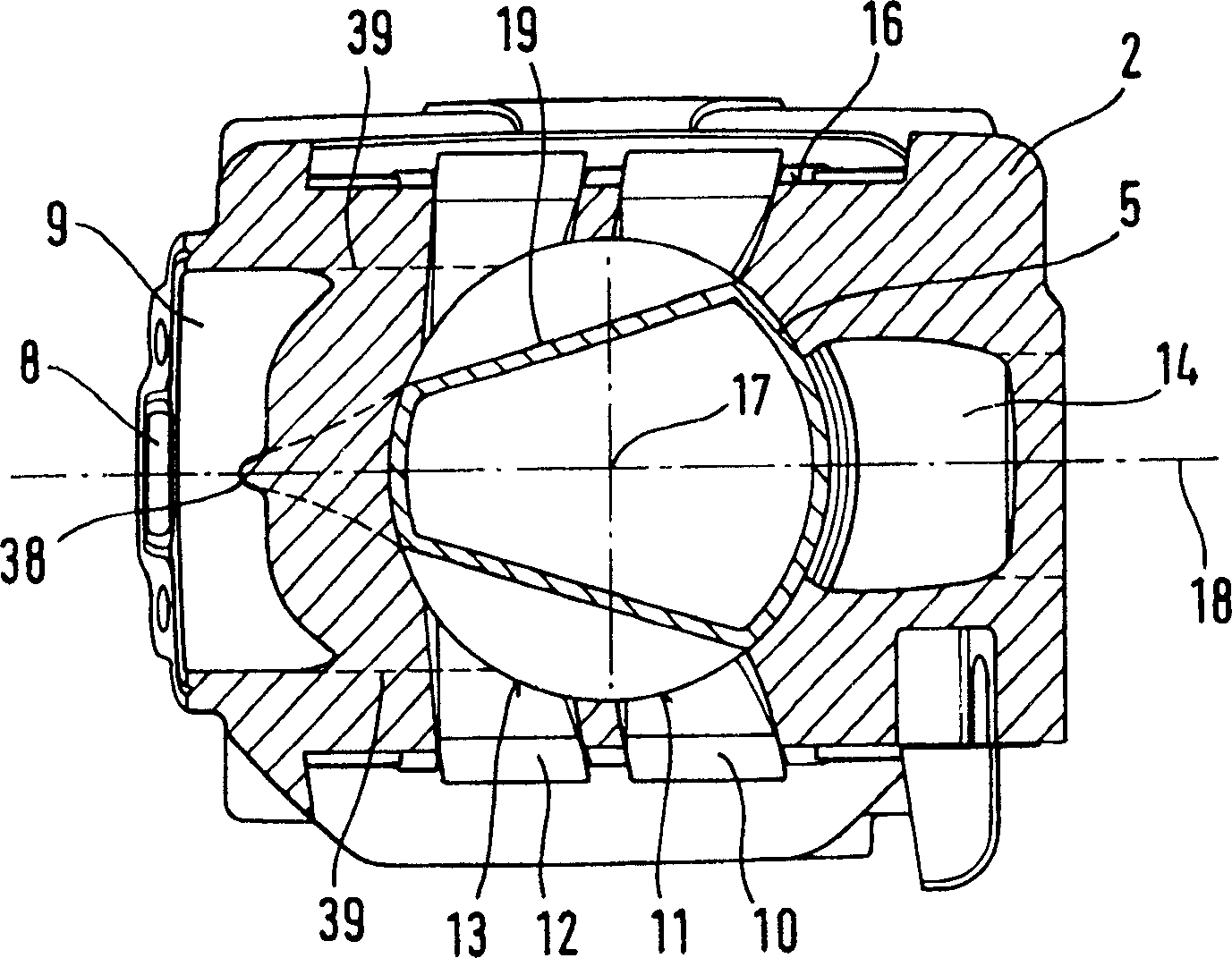

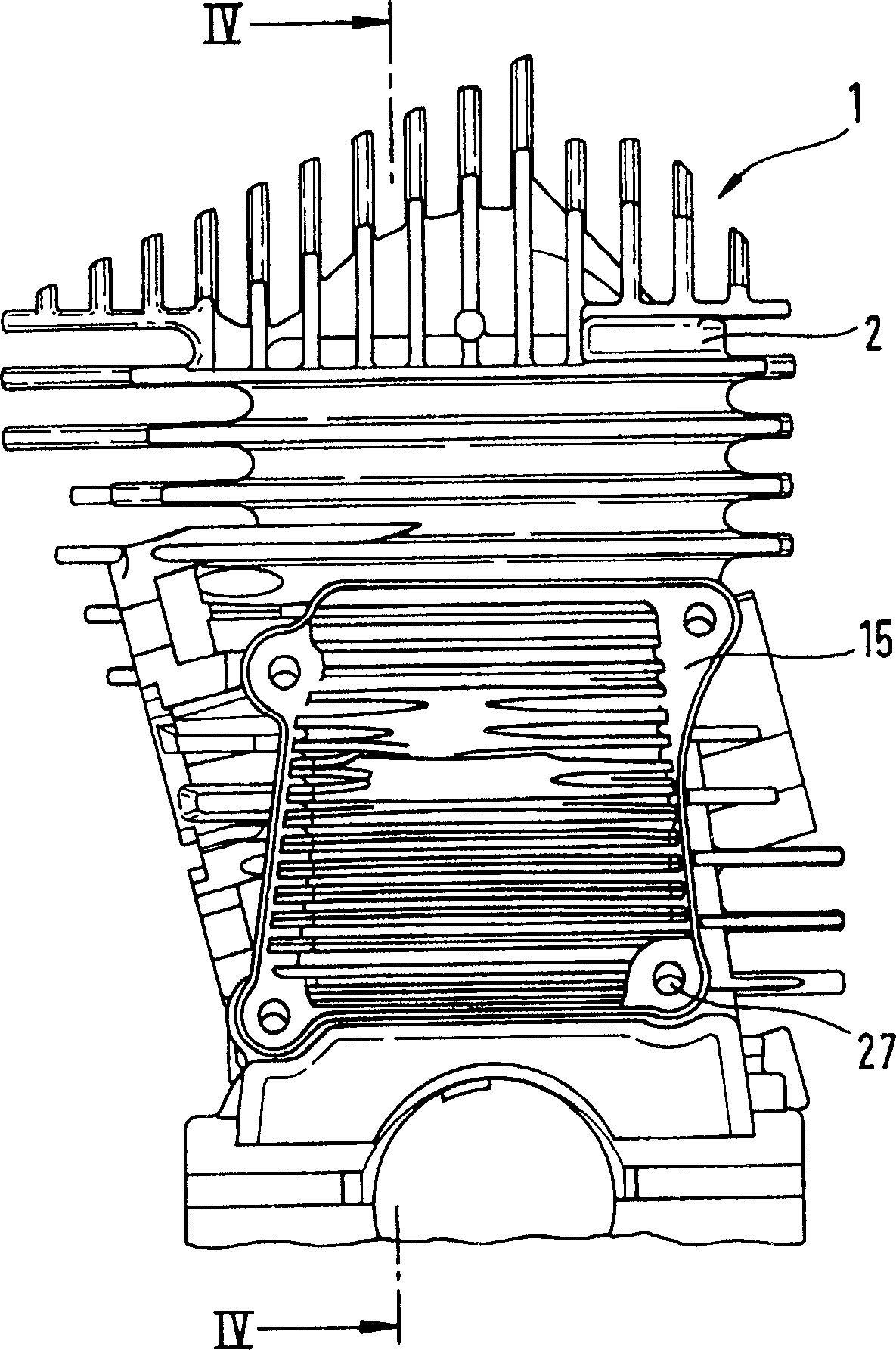

[0021] exist figure 1 The illustrated two-stroke engine 1 includes a cylinder 2 in which there is a Figure 4 Combustion chamber 3 is shown. like Figure 4 Combustion chamber 3 is delimited by piston 5 as shown. The piston 5 drives the cylinder supported in the crankcase 4 through a crank connecting rod. figure 1 The crankshaft 7 is shown. Crank connecting rod 6 is fixed on the piston 5 with a piston pin 21, in Figure 4 The piston is shown in dashed lines in . The crankcase 4 communicates with the combustion chamber 3 through the overflow pipe groove at the predetermined position of the piston 5 . The overflow pipe grooves 10 and 12 are open to the outside of the cylinder. The inner walls 31 of the overflow pipe grooves 10 and 12 are designed on the cylinder. The overflow pipe grooves 10 and 12 are designed as ear canals, so that the inner wall 31 runs curved in the direction of the cylinder longitudinal axis 17 . The overflow ducts 10 and 12 are surrounded on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com