Corrughted paper board processing machine and method for producing corrugated paper board

A processing machine, corrugation technology, applied in the direction of machining/deformation, printing, printing devices, etc., can solve the problem of no simple and flexible technical solution, and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

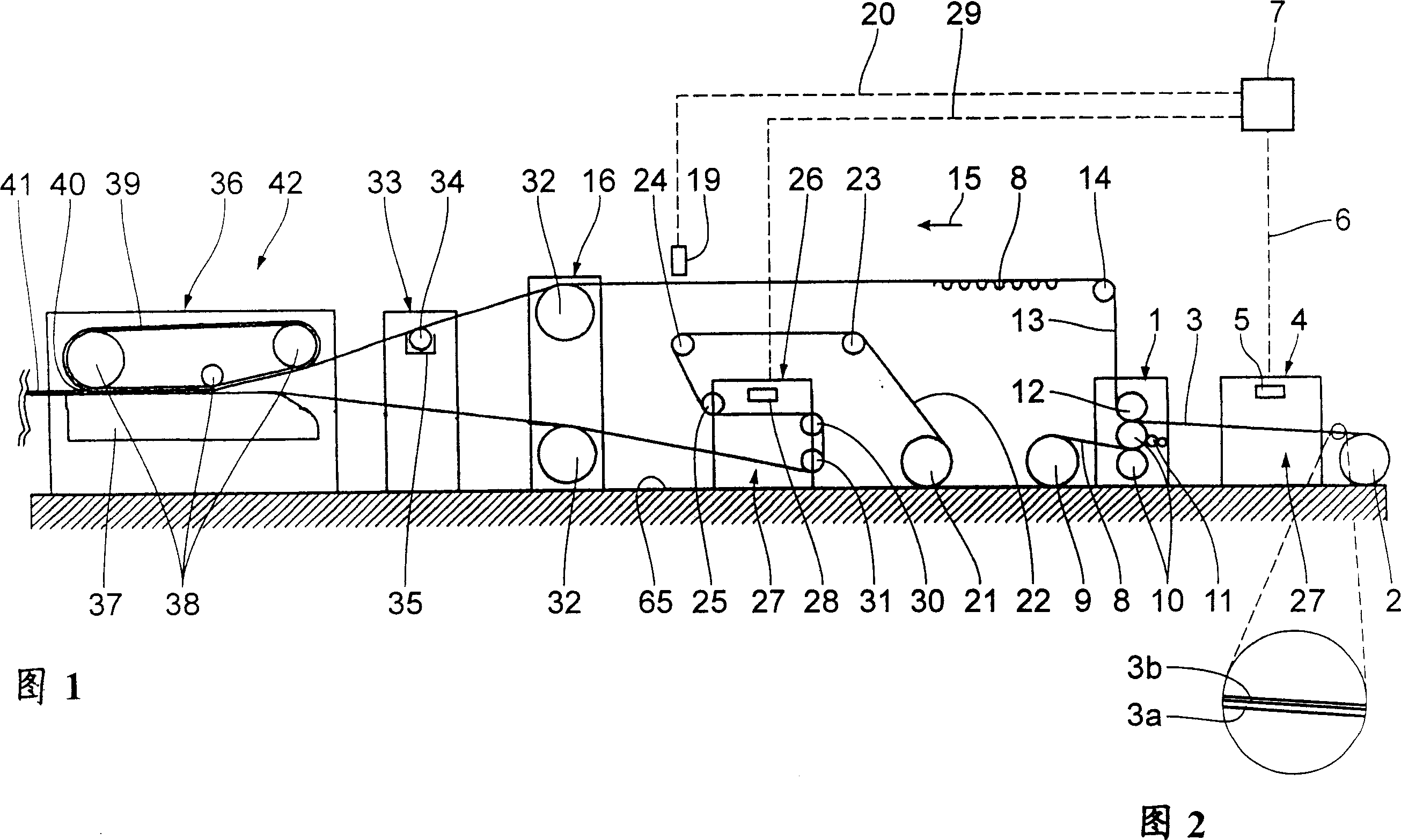

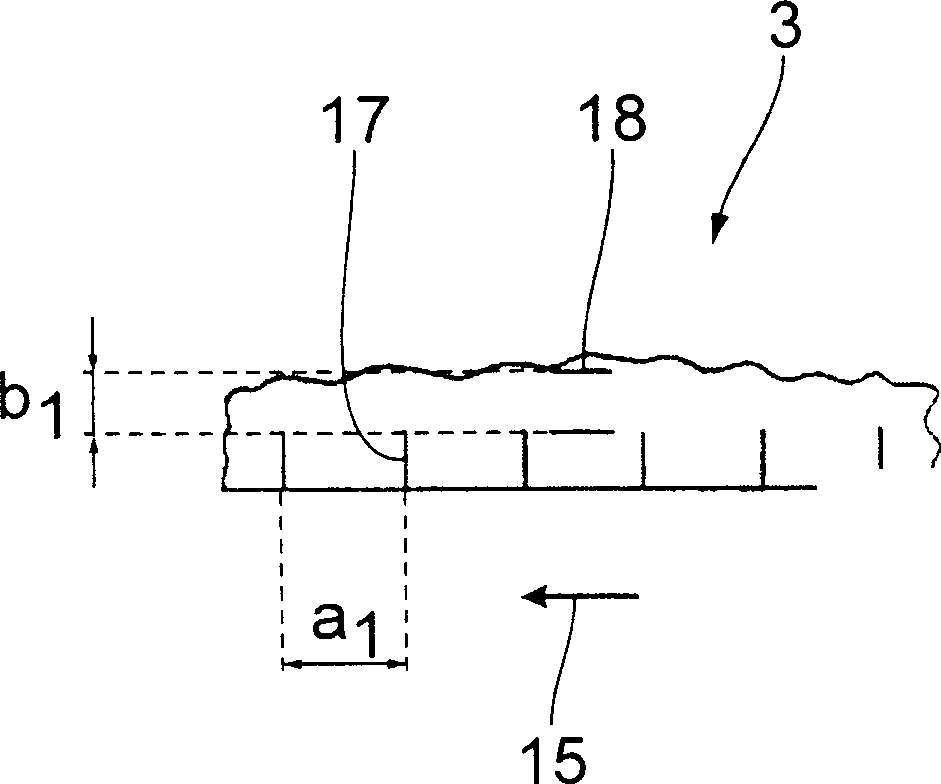

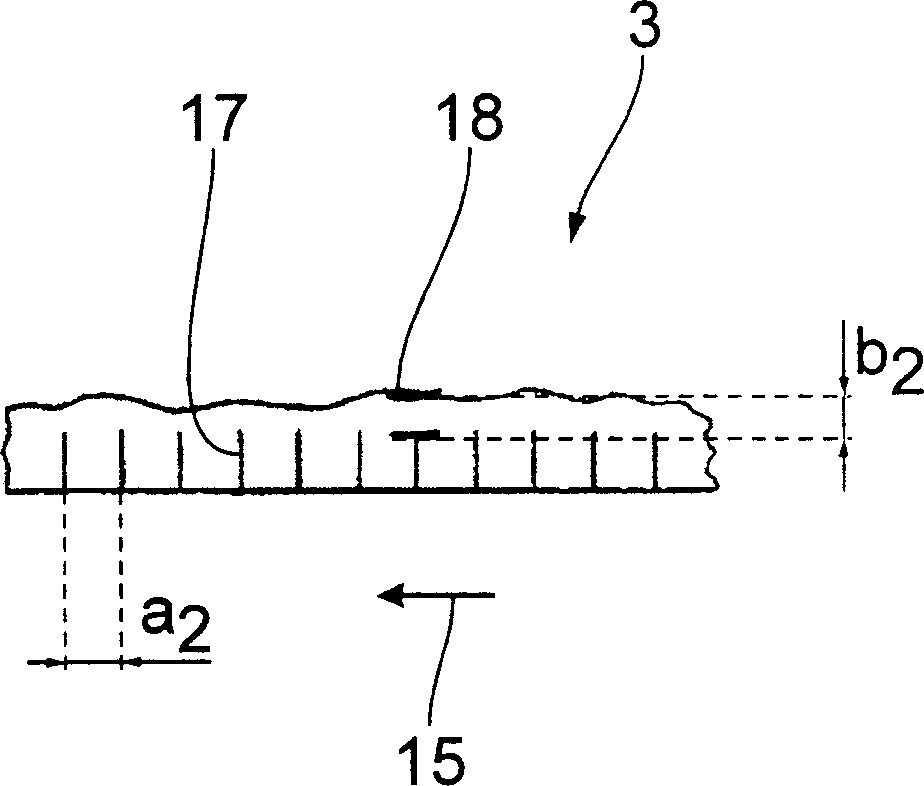

[0020] Below combined with Figure 1 to Image 6 A first embodiment of the present invention will be described. In Figure 1 and Image 6 The corrugating machine shown schematically in , comprises a machine 1 for producing single-face corrugated board. A first material web 3 is fed from a first unwinder 2 to the machine 1 . The material tape is a continuous paper tape. The material web 3 forms a base web for the corrugated cardboard produced on the machine 1 . FIG. 2 is a partially enlarged side view of the first material strip 3 . It comprises a base layer 3a with a base layer 3b which improves the printing quality. The thickness ratio of the base layer 3a and the base layer 3b is unrealistic in the scale of FIG. 2 . In practice, the base layer 3b is much thinner than the thickness shown in FIG. 2 compared to the base layer 3a. The material web 3 does not necessarily contain the bottom layer 3b when the material web 3 is rolled up; the bottom layer 3b can also be applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com