Elastic suede knitted fabric containing spandex and brushing process thereof

A technology for knitted fabrics and suede, which is applied in the direction of fabric surface trimming, textile and paper making, and roughening. It can solve the problems of high friction of fabrics, unsuitable processing of elastic knitted fabrics, and fabric deformation. It achieves good two-way elasticity and skin touch. Excellent, excellent warmth retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

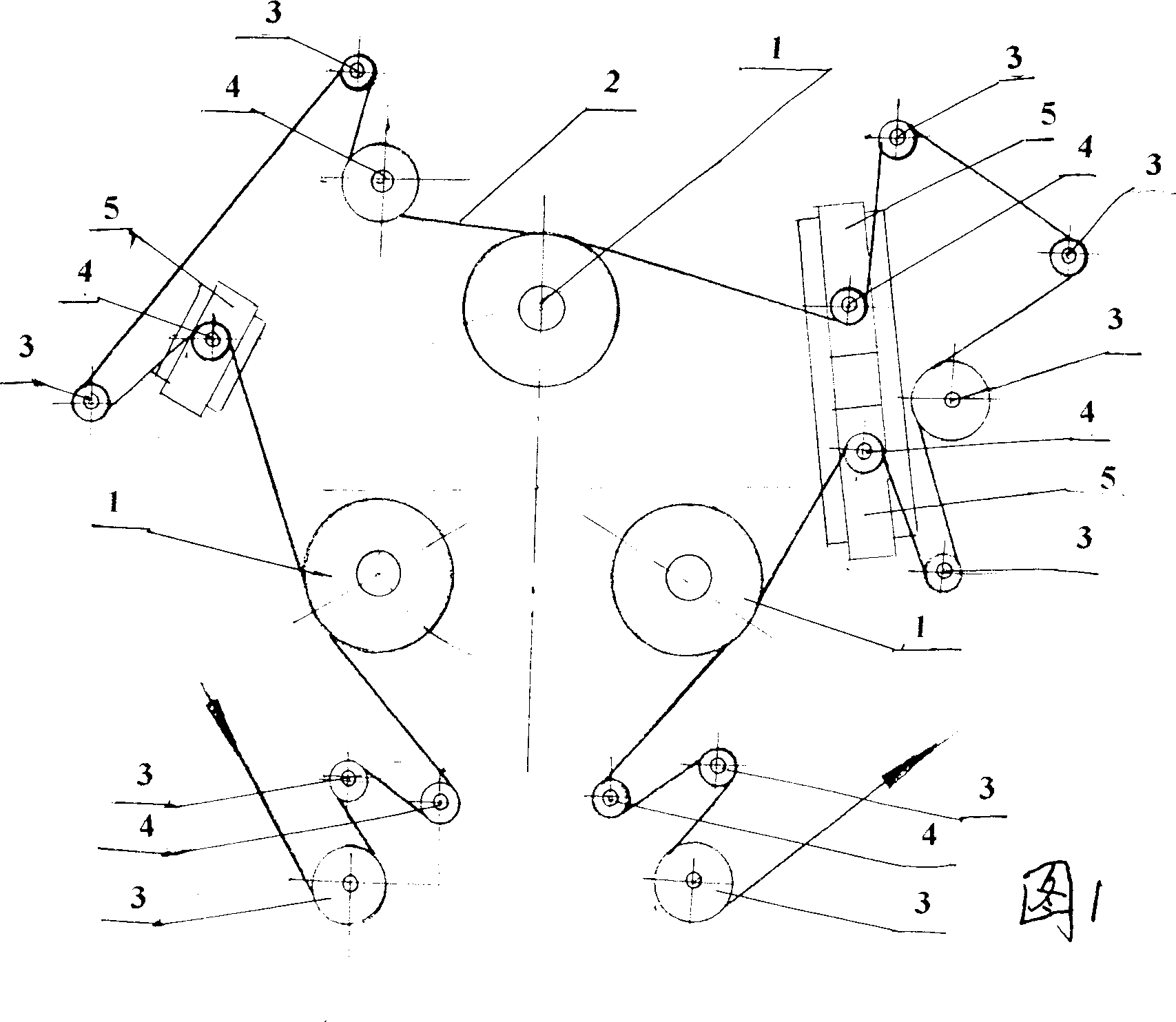

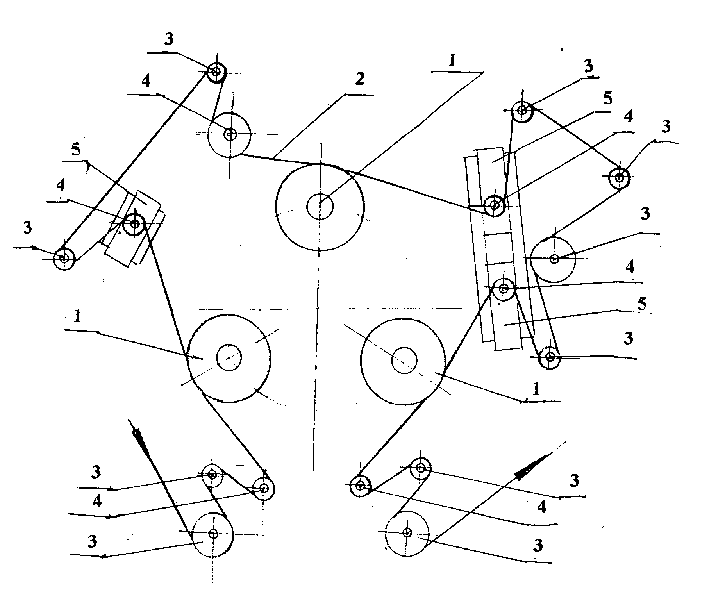

[0011] The present invention will be further described in conjunction with an embodiment and accompanying drawings.

[0012] The name of the product is SQ velvet Lycra knitted underwear fabric. It is made of 50% J18.2tex (32sTK) combed long-staple cotton yarn with 4.4tex (40D) spandex elastic yarn (that is, Dupont Lycra yarn), and is knitted into double-sided fabrics. The rib weave is made by interweaving a 40D spandex elastic bare silk in each course, and then dyeing and finishing and brushing the front and back sides of the fabric by the brushing process of the present invention. The underwear made of this fabric is comfortable to wear, soft to the touch, fine and uniform, uniform in length, good in warmth retention, and good in touch when in contact with the skin.

[0013] Fig. 1 is the schematic diagram of brushing process of the present invention. The process is as follows: the fabric 2 is driven by a transmission mechanism composed of several driving rollers 3 and suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com