Electric walking tillage machines

A tiller and electric motor technology, which is applied in the field of walking electric soil tillage machines, can solve the problems of not being able to show the installation position of the tiller, and achieve the effects of enhancing the linear driving ability and operability, reducing the burden, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

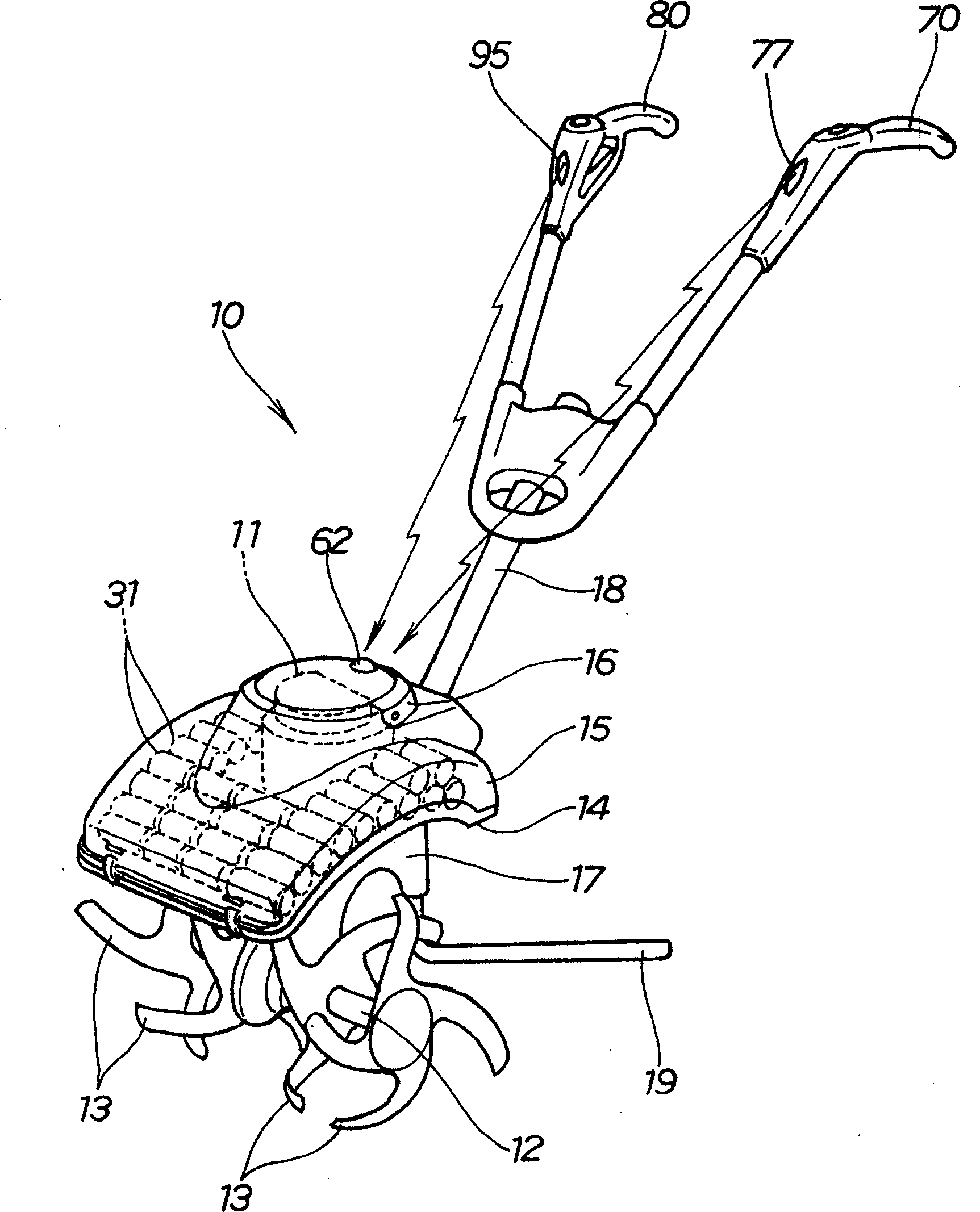

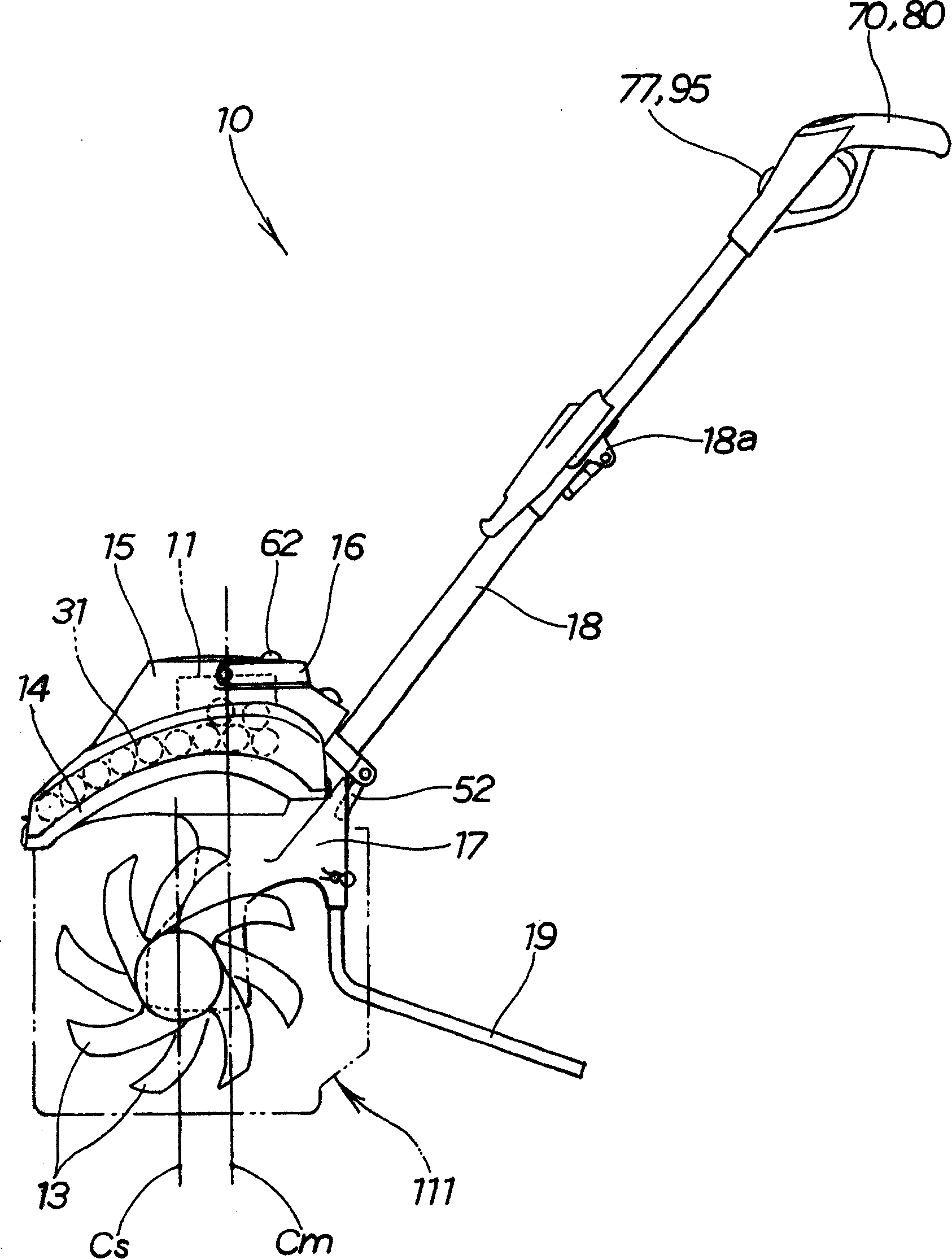

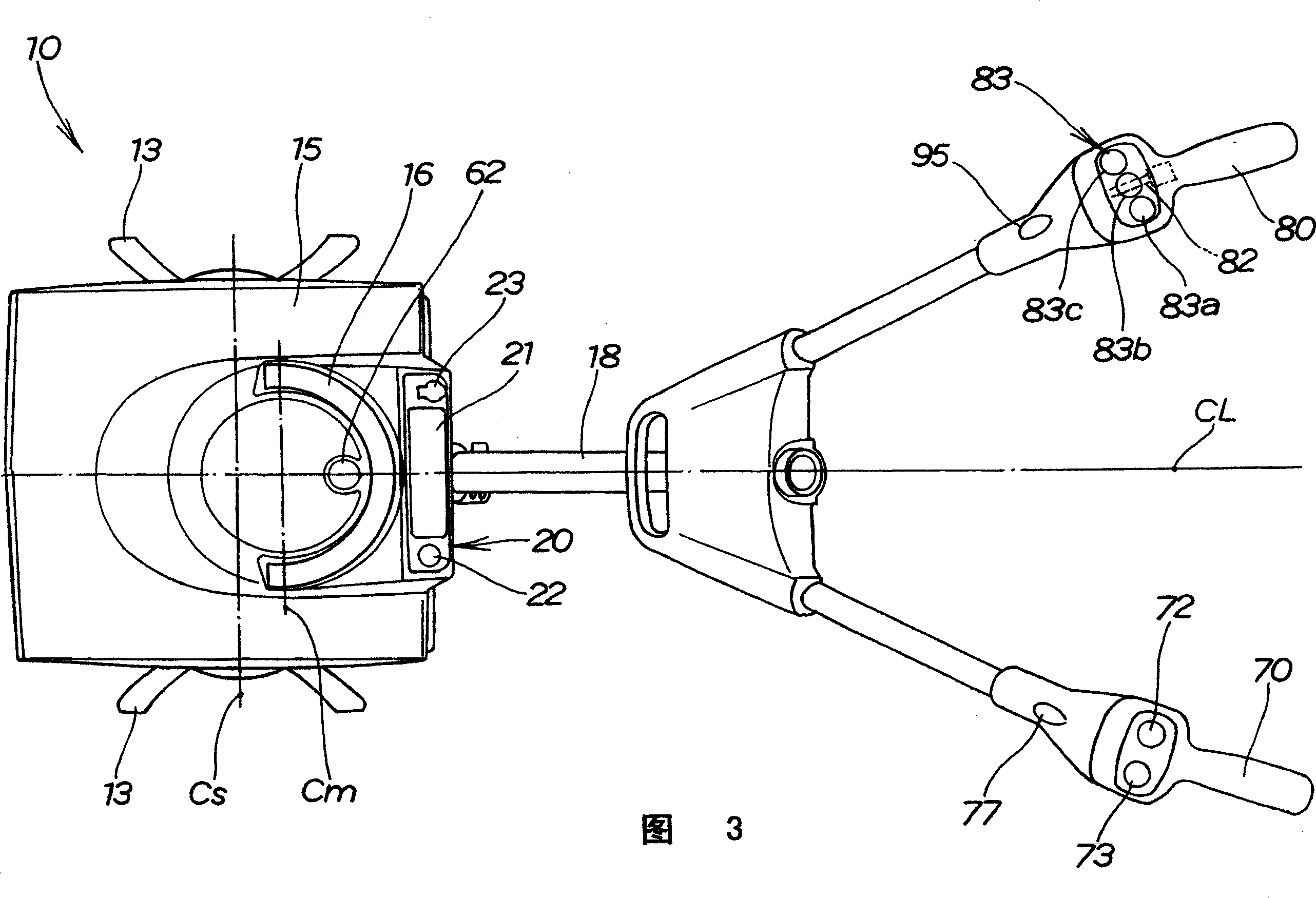

[0034] The walking electric tiller 10 is a self-propelled front-tooth tiller configured to transmit drive power from the motor 11 (ie, the drive source of the tiller 10) to the tiller shaft 12, through the left and right ends of the tiller shaft 12. Rotation of the plurality of tilling claws 13 at the top, so that the cultivator can travel on the cultivated land, and use the rotating tilling claws 13 to cultivate the land. The tilling claw 13 is covered with an upper baffle 14 , and the upper cover 15 covers the upper surface of the baffle 14 . The tillage shaft 12 is a rotating shaft extending horizontally (i.e. along the width direction of the body frame 17) between the opposite inner surfaces in the tiller body frame 17, and the baffle plate 14 is a casing designed mainly to prevent soil and Soil and sand scattered.

[0035] The electric tiller 10 is so small that an operator can carry it with his or her single arm by grabbing a carrying handle 16 provided on top of an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com