Silk-sucking mouth

A technology of suction mouth and channel, which is applied in the field of suction nozzle, can solve the problems of large requirements and energy waste, and achieve the effect of low power consumption, simple structure and good suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

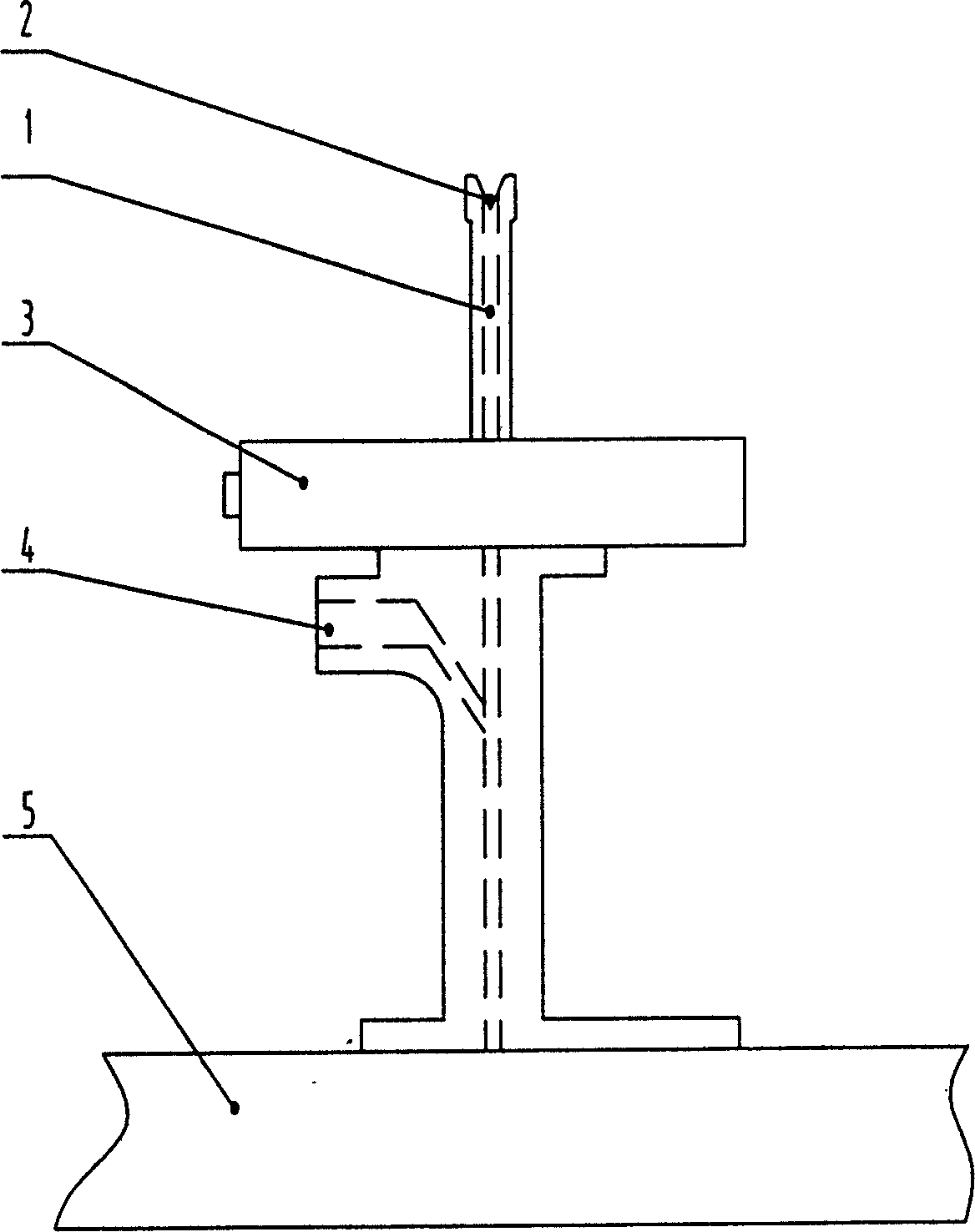

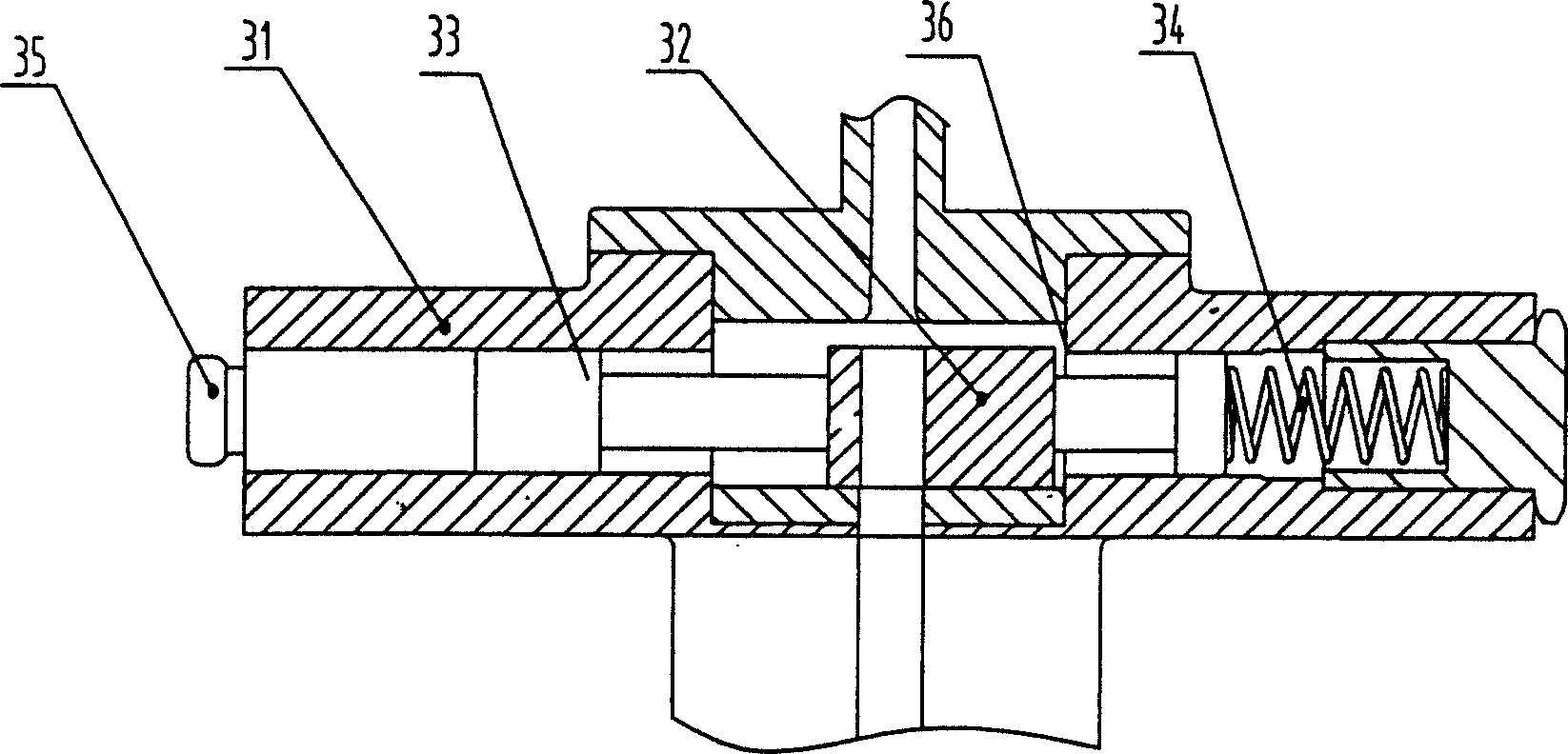

[0013] A silk suction nozzle according to the present invention installed on the silk suction and walking channel 5, it includes a silk suction channel 1 with a V-shaped silk suction port 2 at the top, and the silk suction channel 1 is divided into an upper silk suction channel and a lower silk suction channel. The silk suction channel, the lower section of the silk suction channel communicates with the silk suction and walking channel 5 . A switch seat 3 is arranged between the upper segment suction silk channel and the lower segment suction silk channel, and the switch seat 3 adopts pneumatic control. The switch seat 3 includes a seat body 31, a plug 32, a piston 33, a spring 34 and an air inlet 35. Wherein the seat body 1 is provided with a circular slideway, the diameter of the middle part of the slideway is large and the diameters of both sides are small; the cylindrical plug 32 is provided with a through hole connecting the upper and lower suction silk passages; the plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com