Method for preparing high specific surface metal oxide

A high specific surface, metal compound technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of generating a large amount of waste, difficult conditions to control, long time, etc., to achieve waste generation The effect of less amount, easy control of conditions, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 CeO 2 Precursor preparation

[0015] The cerium nitrate is dissolved in water to prepare an impregnating liquid, and activated carbon carrier is added for impregnating for 0.1-10 hours. The surface area of activated carbon is 100-3000m 2 / g. Evaporate the solution under stirring, then bake at 100-120°C for 10-24 hours to obtain CeO 2 . CeO 2 The weight percentage of loading is in the range of 1-200%.

Embodiment 2

[0016] Example 2 ZrO 2 Precursor preparation

[0017] Zirconium nitrate or zirconium oxychloride is dissolved in water to prepare an impregnating solution, and activated carbon carrier is added for impregnating for 0.1-10 hours. The surface area of activated carbon is 100-3000m 2 / g. Evaporate the solution under stirring, then bake at 100-120°C for 10-24 hours to obtain ZrO 2 precursor. ZrO 2 The weight percentage of loading is in the range of 1-200%.

Embodiment 3

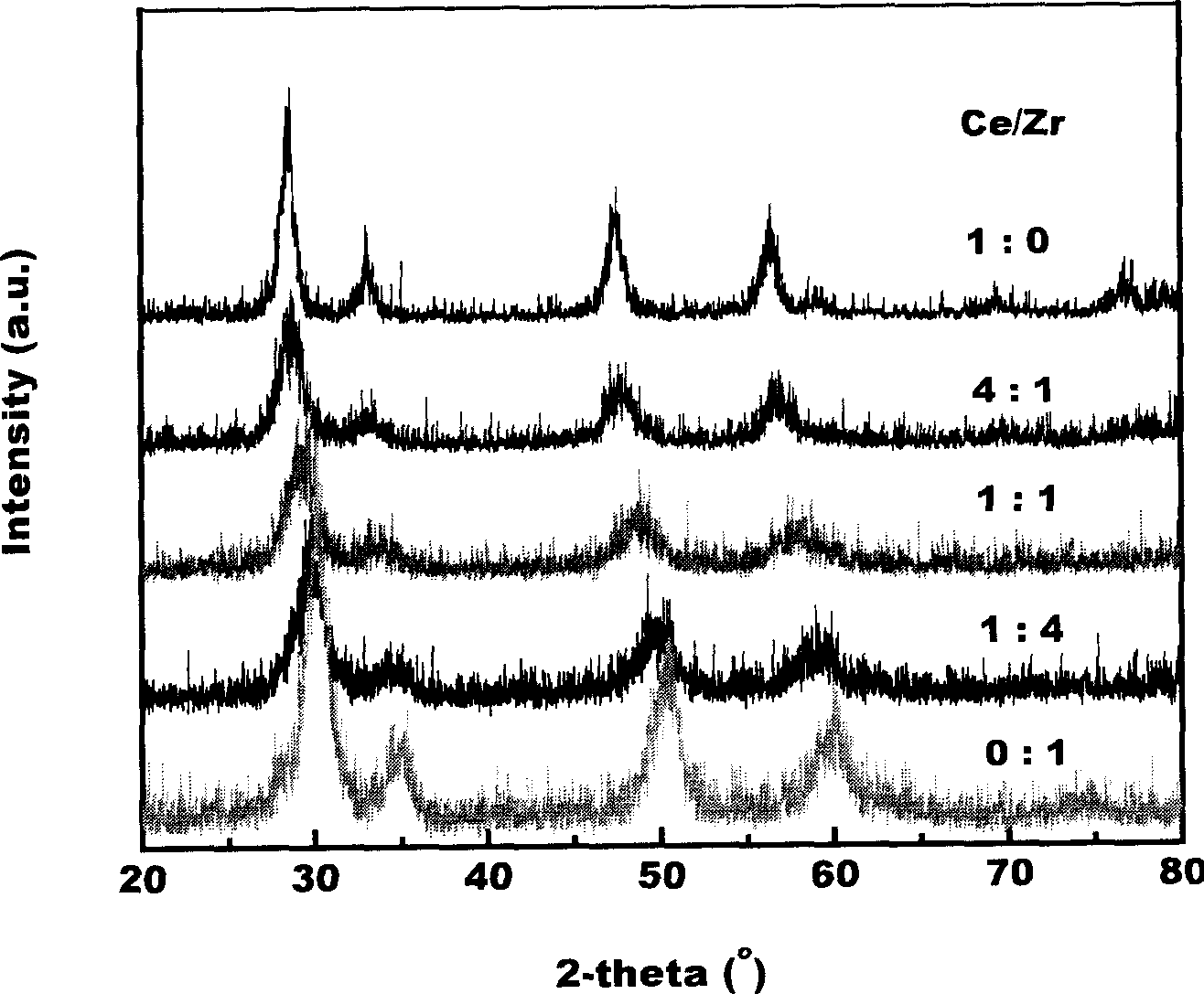

[0018] Example 3 Ce x Zr 1-x o 2 Preparation of solid solution precursors

[0019] Cerium nitrate and zirconium salts (such as zirconium nitrate, zirconium oxychloride etc.) Bake at ℃ for 10-24 hours to obtain Ce x Zr 1-x o 2 Solid Solution Precursor. Ce x Zr 1-x o 2 The weight percentage of loading is in the range of 1-200%.

[0020] Ce x Zr 1-x o 2 The solid solution precursor can also be impregnated step by step, that is, impregnating the cerium nitrate first and then impregnating the zirconium salt, or impregnating the zirconium salt first and then impregnating the cerium nitrate. After each step of impregnation, the solution needs to be evaporated under stirring, and then baked at 100-120°C for 10-24 hours, and finally Ce x Zr 1-x o 2 Solid Solution Precursor.

[0021] By changing the amount of cerium nitrate and zirconium salt added, Ce with different Ce / Zr atomic ratios can be prepared x Zr 1-x o 2 Solid Solution Precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com