Horizontal roller-free making process of toughened glass with double curved surface

A technology of toughened glass and its production method, which is applied in glass forming, glass tempering, glass manufacturing equipment, etc., and can solve the problems of high cost of roller table maintenance and heat preservation of heating section, impact on the optical performance of tempered glass, and easy damage to the glass surface, etc. problem, to achieve the effect of small footprint, high yield and good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

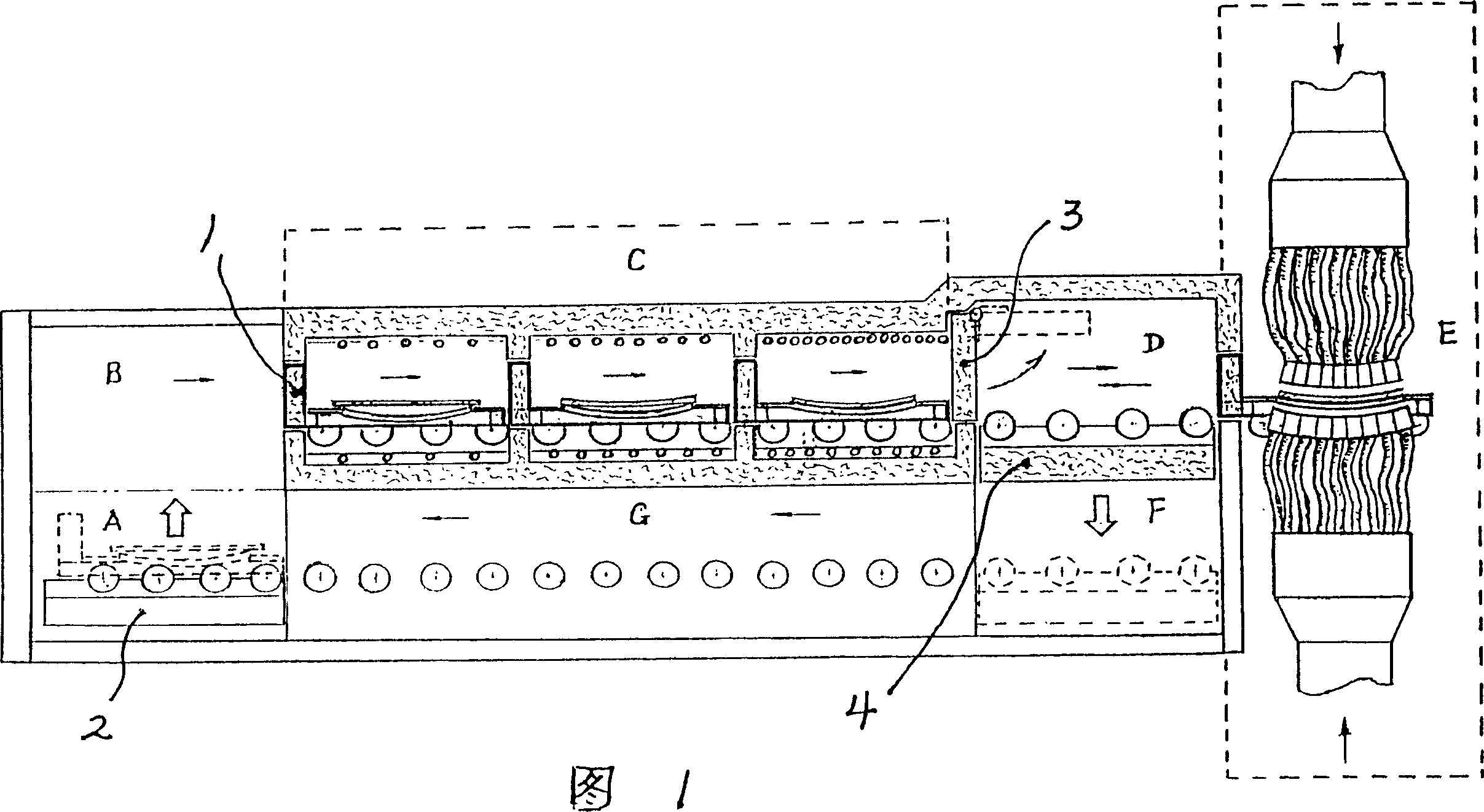

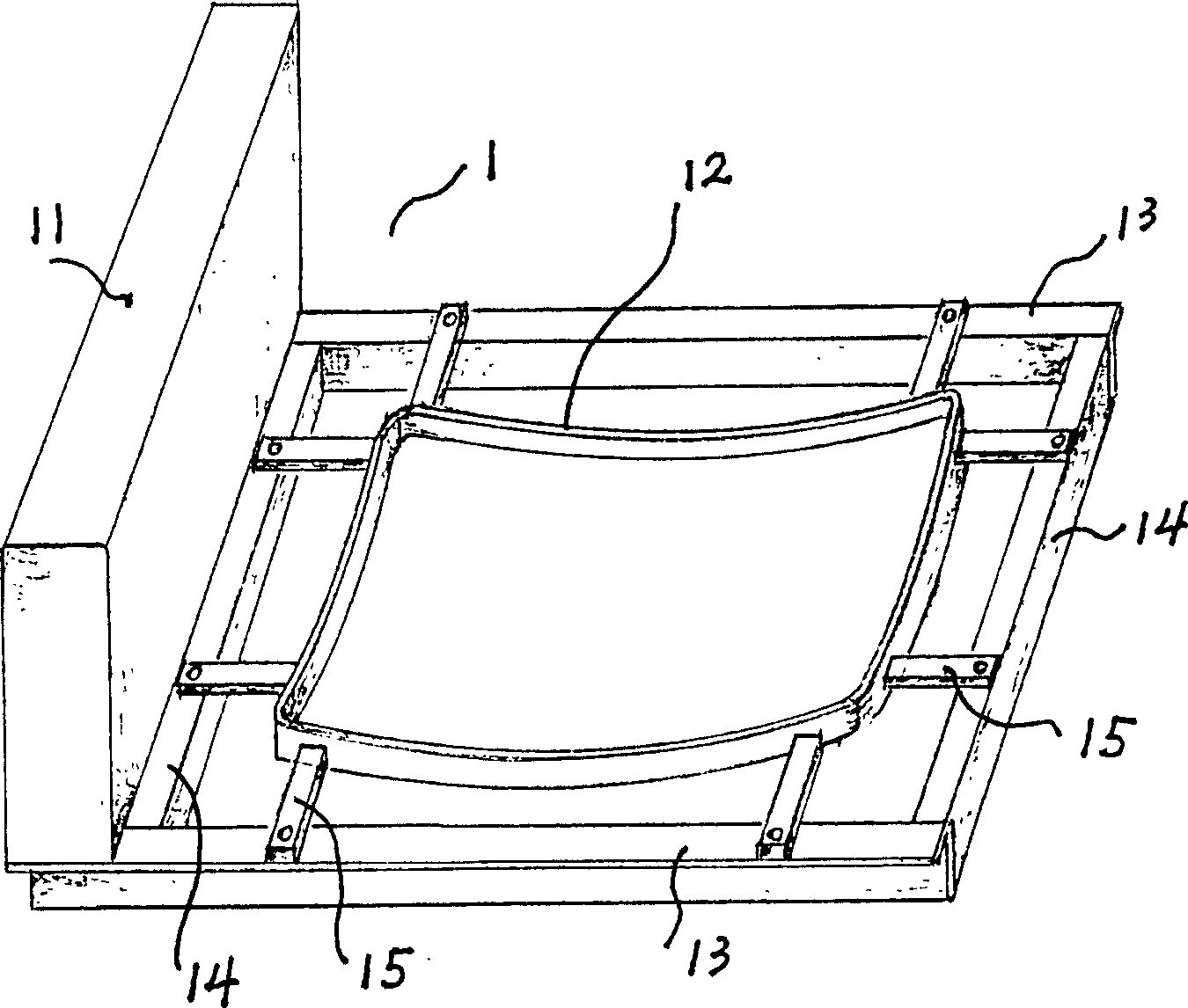

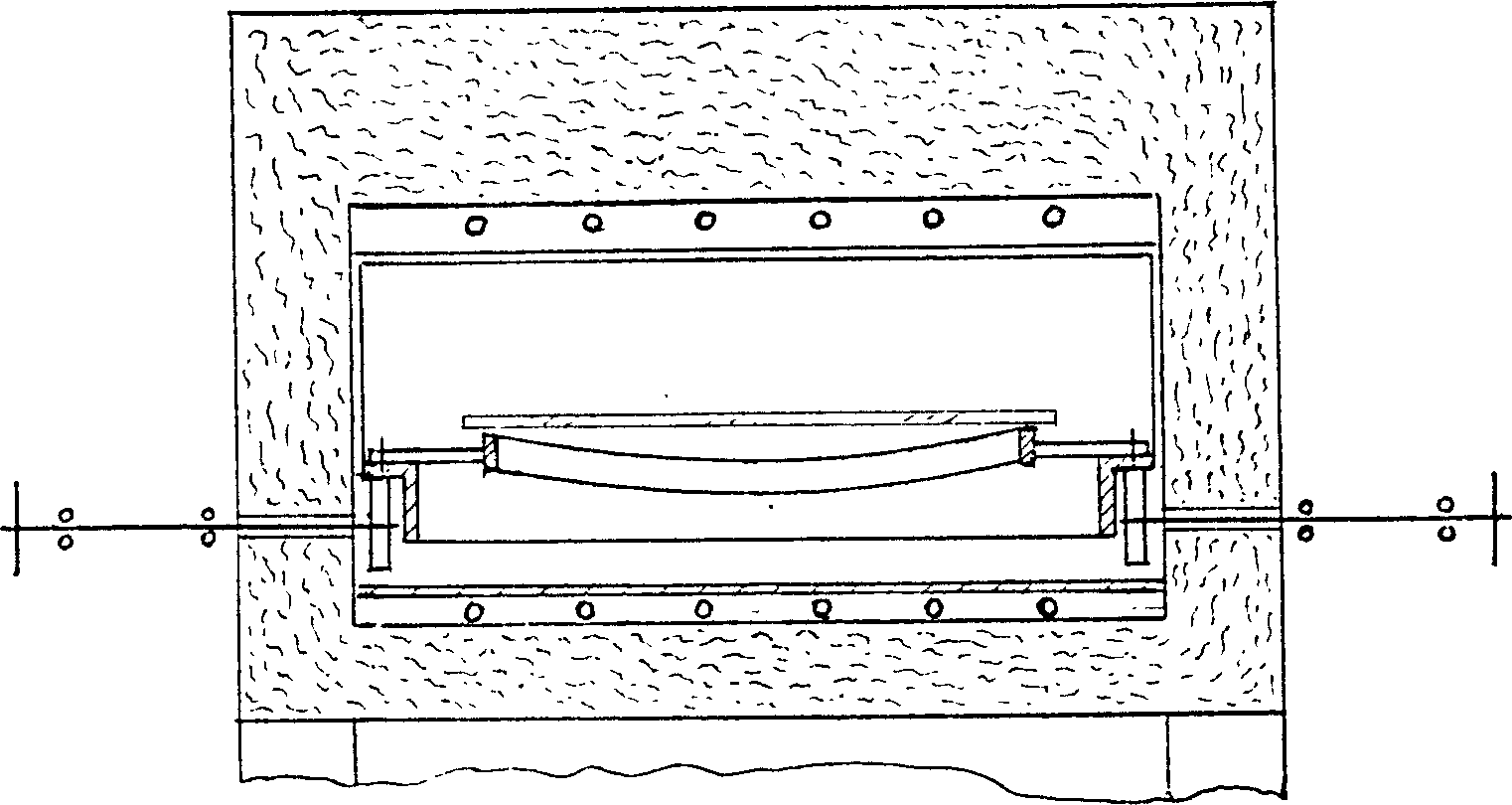

[0010] It can be seen from accompanying drawing 1, a kind of technological flow of the manufacturing method of horizontal non-roller hyperbolic tempered glass. The practice of this embodiment is: first, the plate glass that needs to be bent and tempered is placed on the mold of the "L" shaped car 1, and the "L" shaped car 1 is as follows: figure 2 As shown, the vertical surface is provided with an insulating layer 11, and the horizontal plane is an "L" shaped trolley 1 provided with a frame-type hyperboloid forming mold 12 in the middle of the frame. The "L" shaped trolley 1 can move horizontally along the raceway, and the horizontal plane is two The side is provided with a guide rail 13 with a straight edge that can run along the corresponding roller raceway. The middle part of the "frame" formed by the guide rail 13 and the reinforcing rods 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com