Active organic LED display and its making method

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, instruments, electric solid-state devices, etc., can solve problems such as difficult driving circuit testing or repairing, and achieve high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

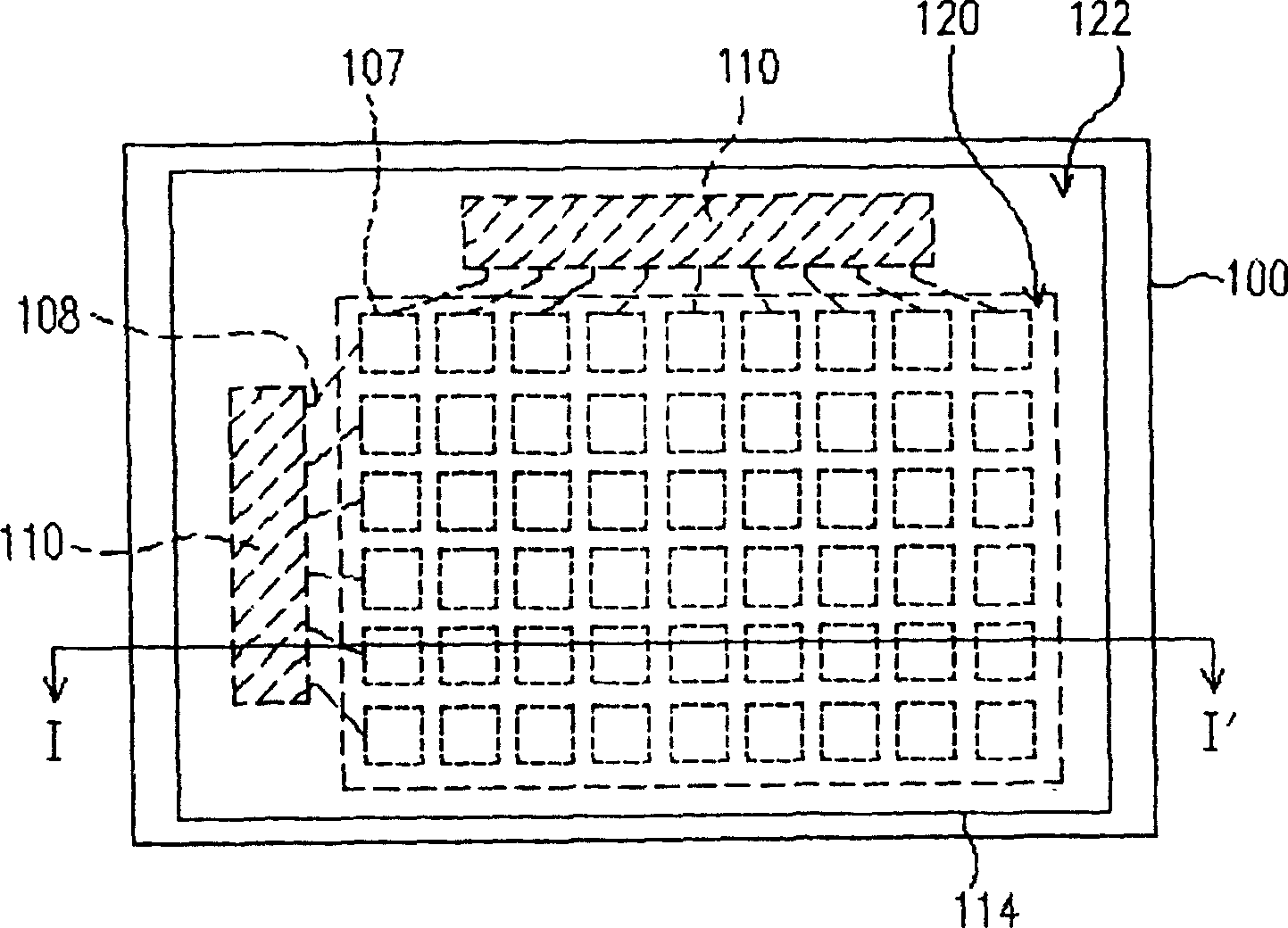

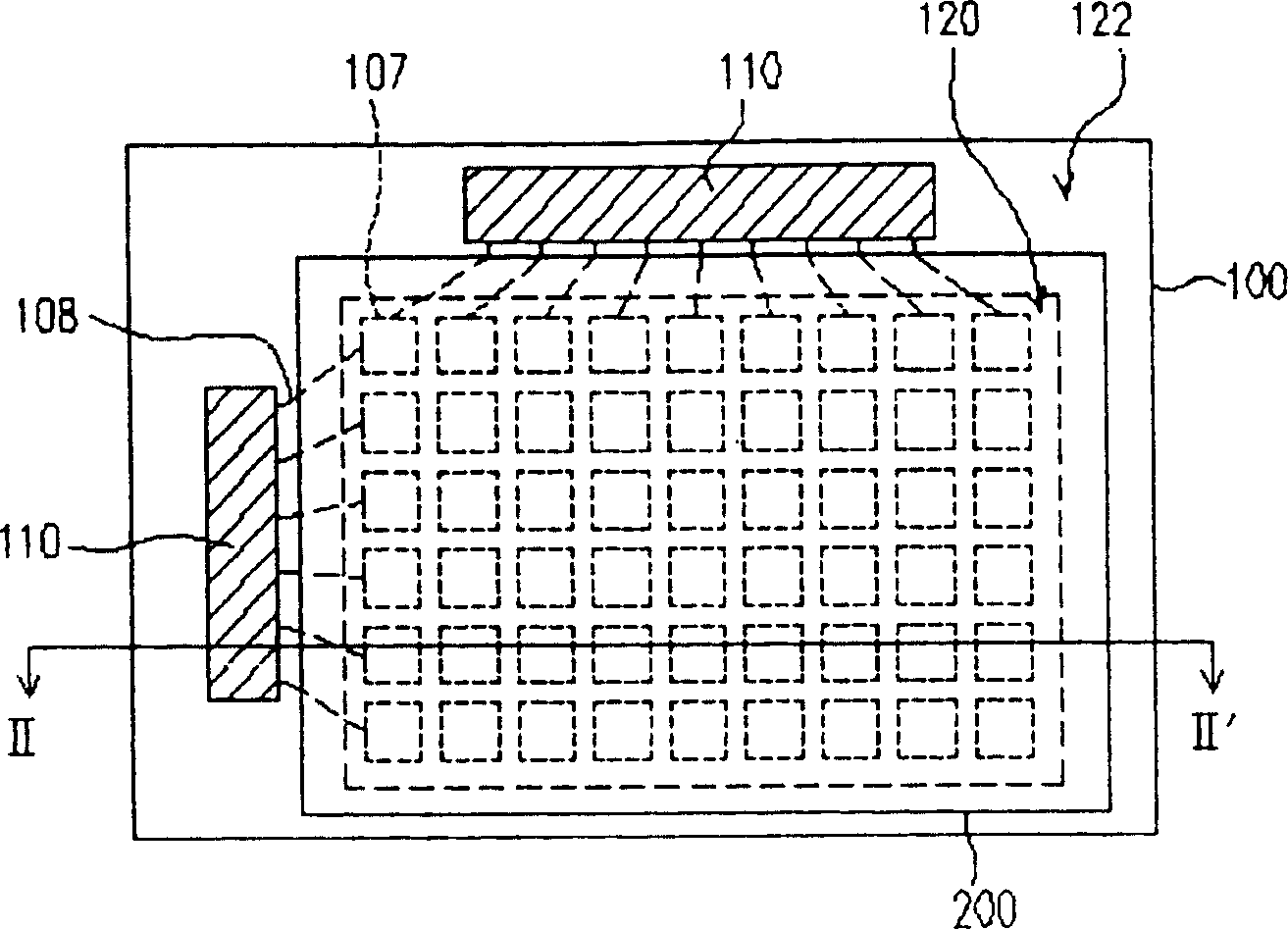

[0039] image 3 is a schematic top view of an active organic light emitting diode display according to a preferred embodiment of the present invention; Figure 4 for image 3 Schematic sectional view from II-II'.

[0040] Please also refer to image 3 and Figure 4 The manufacturing method of the active organic light emitting diode display of the present invention is to firstly provide a substrate 100, wherein the substrate 100 has a light emitting region 120 and a non-light emitting region 122, and the light emitting region 120 of the substrate 100 has formed several arrays Pixel structures 107 , wherein each pixel structure 107 includes an active device and an anode layer 102 , a light emitting layer 104 and a cathode layer 106 .

[0041] Here, the active device in the pixel structure 107 is composed of at least two thin film transistors. In this embodiment, the active element is composed of two thin film transistors, one of which is responsible for switching and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com