Backlight module

A backlight module and light source technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as deformation, different opening sizes of lamp holder 108, and light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

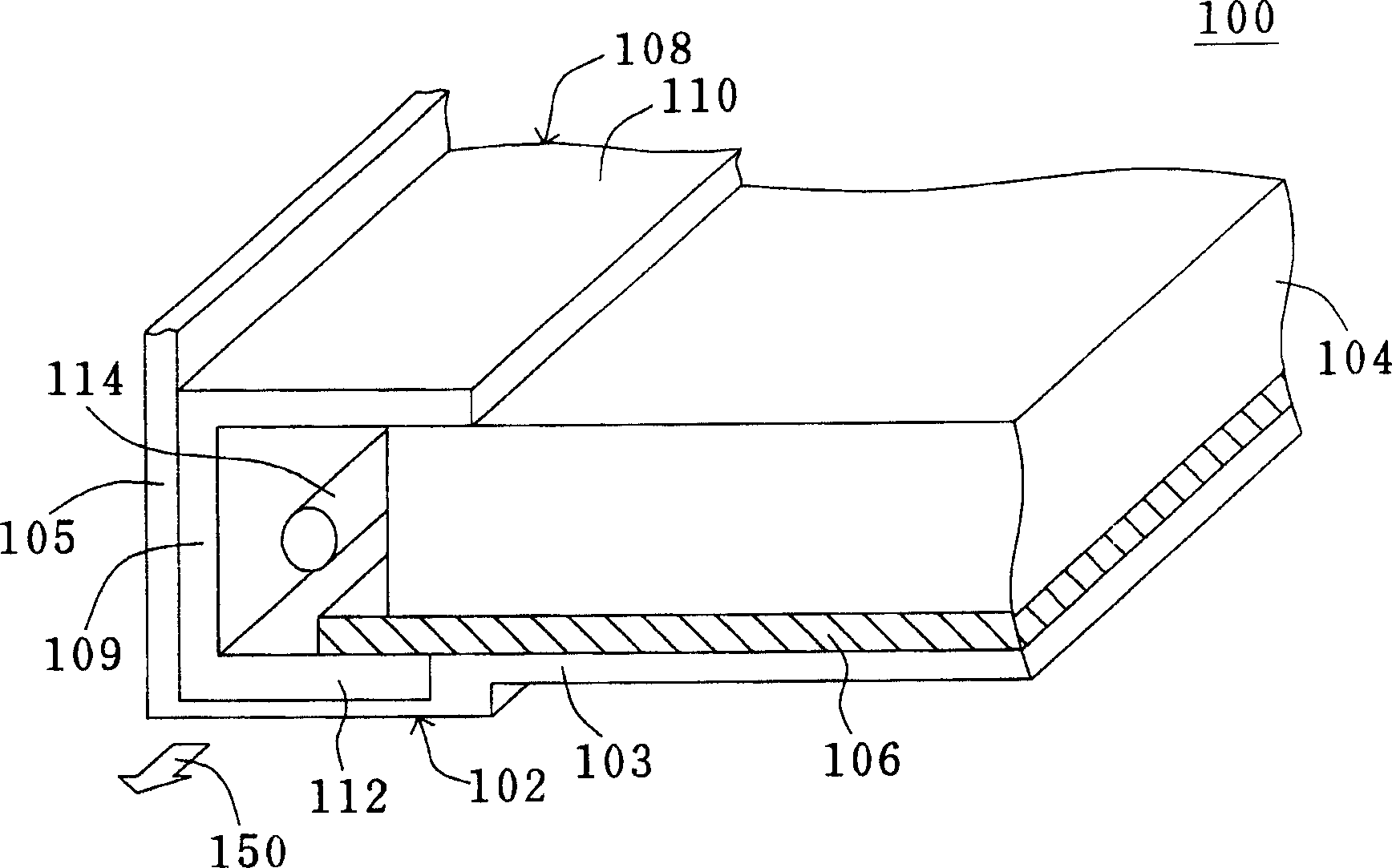

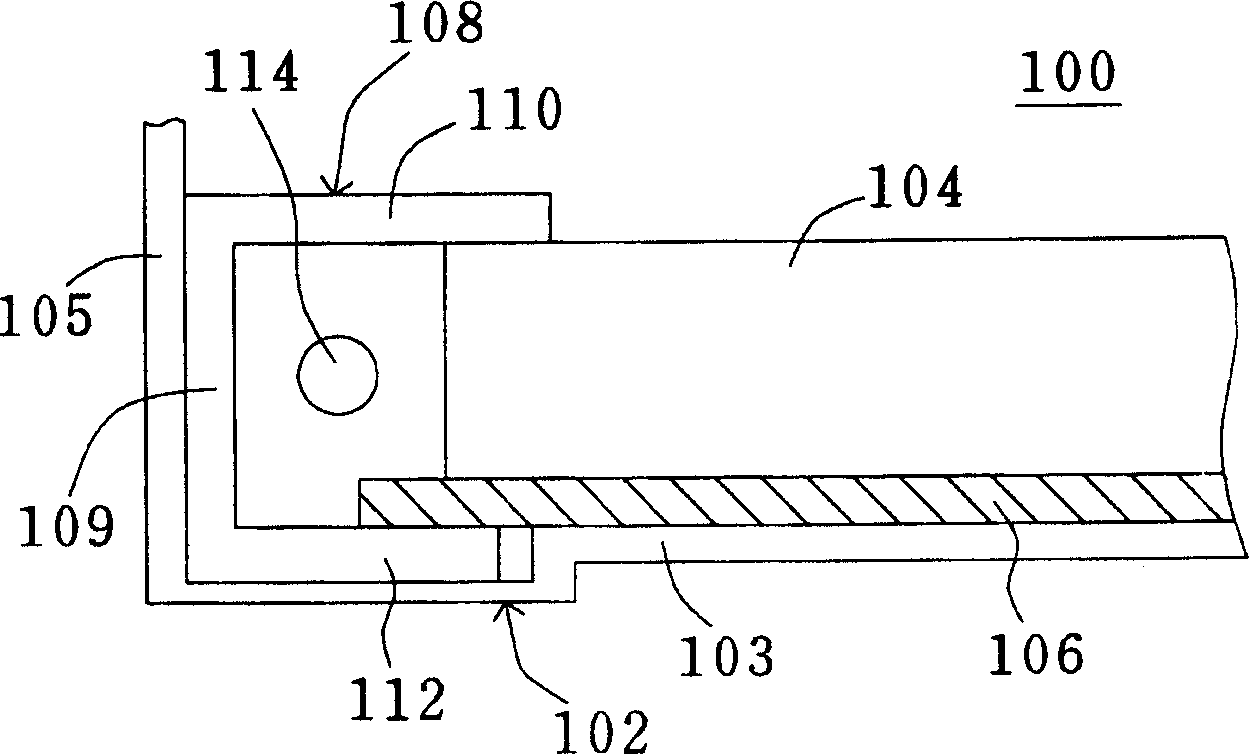

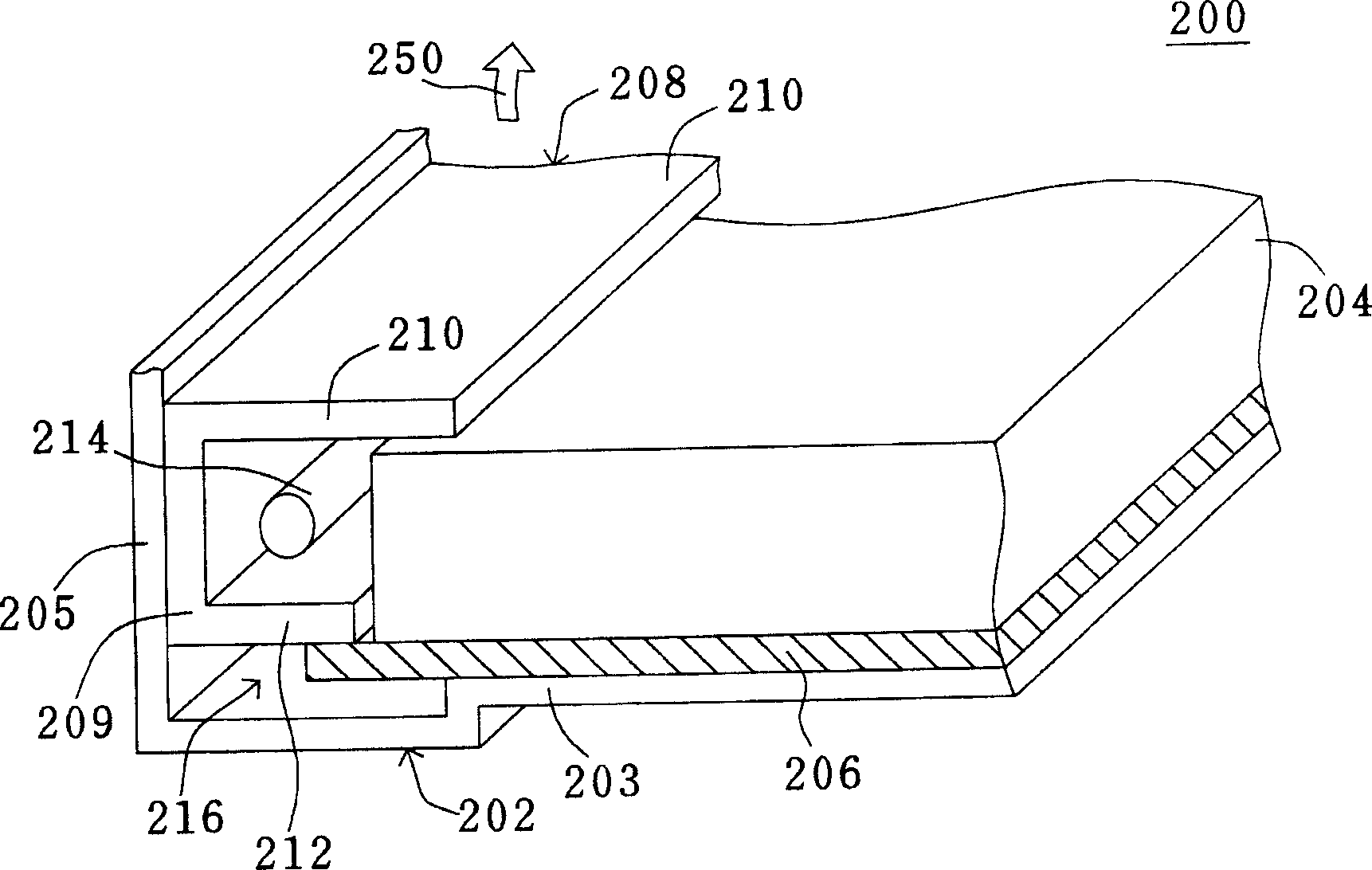

[0013] The present invention specially designs a backlight module, which inserts the lamp socket between the light guide plate and the side plate of the frame, so as to prevent the lamp socket from scratching the light guide plate and the reflection sheet. The consistency of the size of the opening of the lamp holder can be maintained, the occurrence of light leakage can be prevented, and the overall brightness of the backlight module can be improved.

[0014] Please also refer to Figure 2A and Figure 2B , respectively depicting a partial perspective view and a cross-sectional view of a backlight module according to a preferred embodiment of the present invention. exist Figure 2A and Figure 2B Among them, the backlight module 200 includes a frame 202 , a light guide plate 204 , a reflector 206 , a lamp holder 208 and a light source 214 , and the light guide plate 204 , the reflector 206 , the lamp holder 208 and the light source 214 are located in the frame 202 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com