Symmetrical type white rib smoke dryer

A burley tobacco and drying machine technology, applied in the field of tobacco machinery, can solve the problems that are not conducive to accurate control of tobacco leaf processing process parameters, tobacco leaf wind parameters and uneven discharge temperature, complex machine structure, etc., and achieve simple and reasonable structure, The effect of low cost and low height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

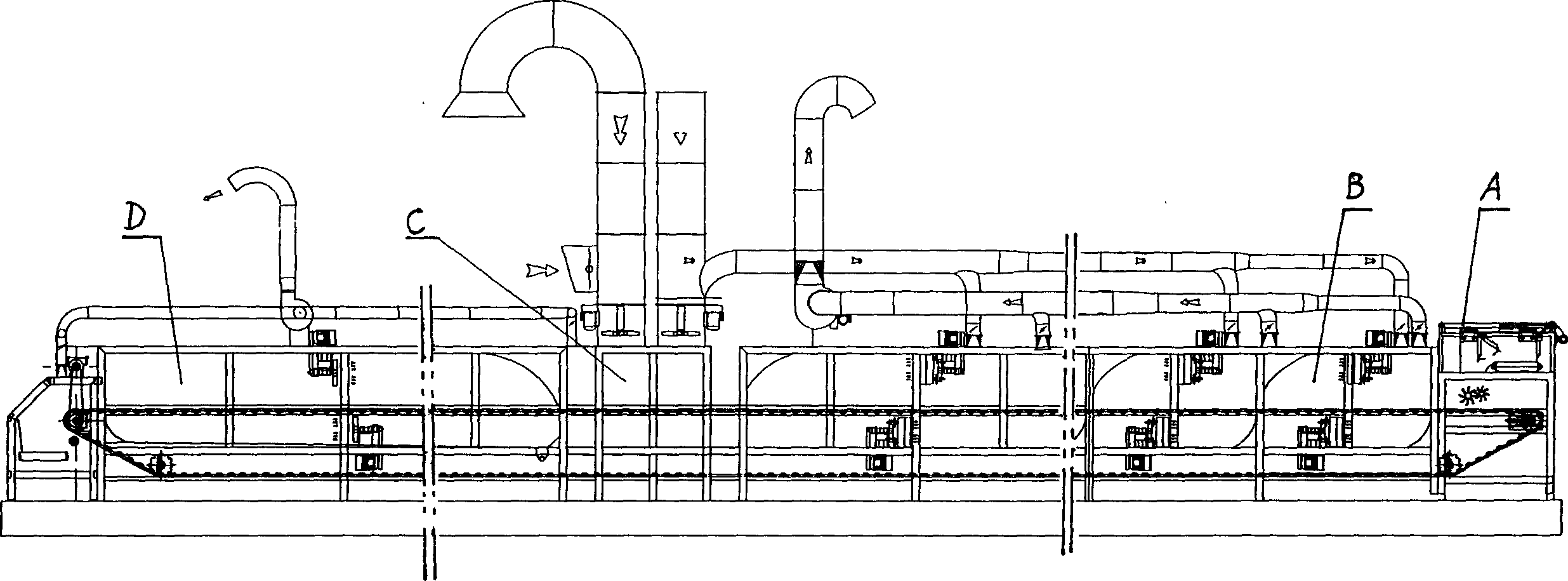

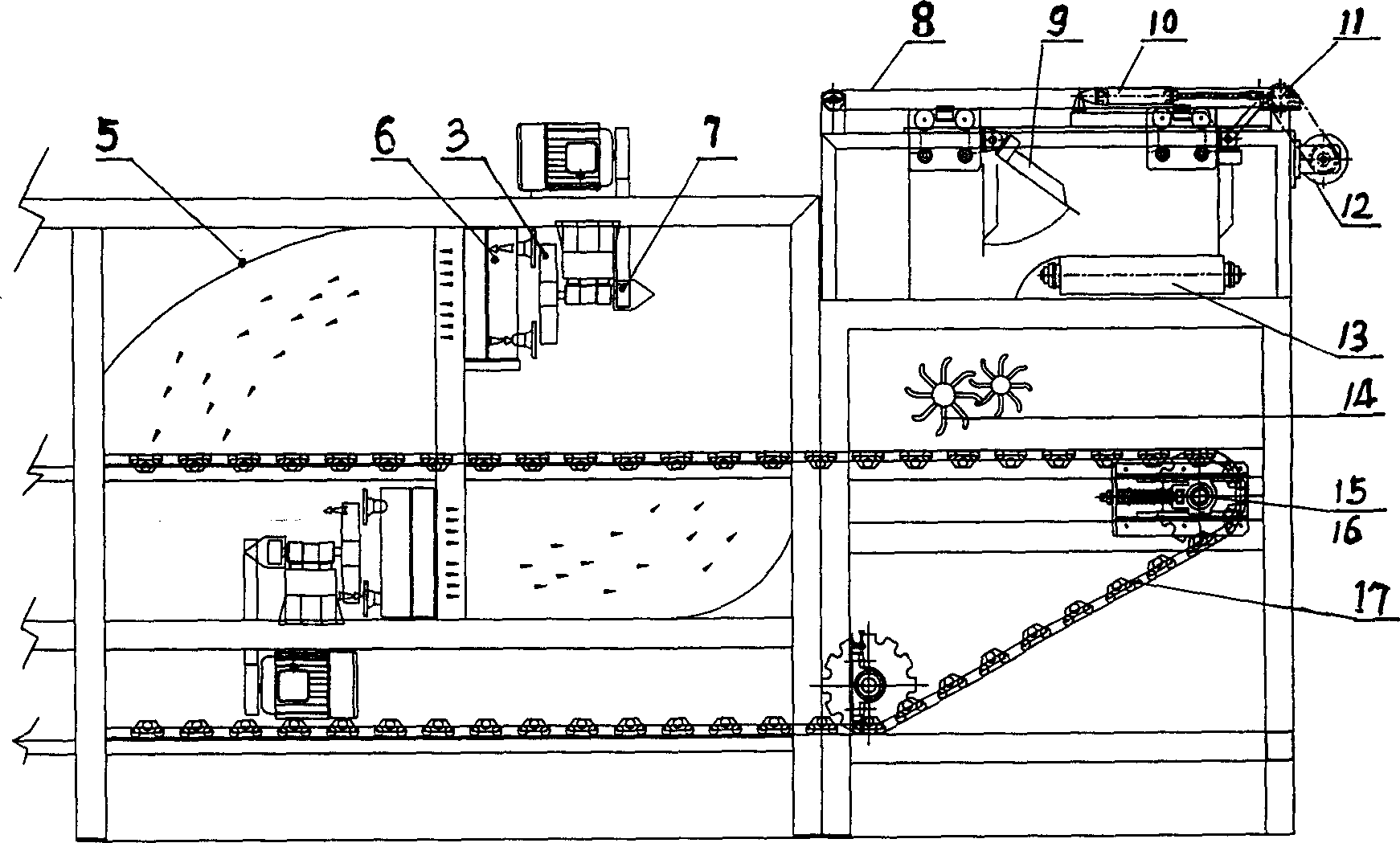

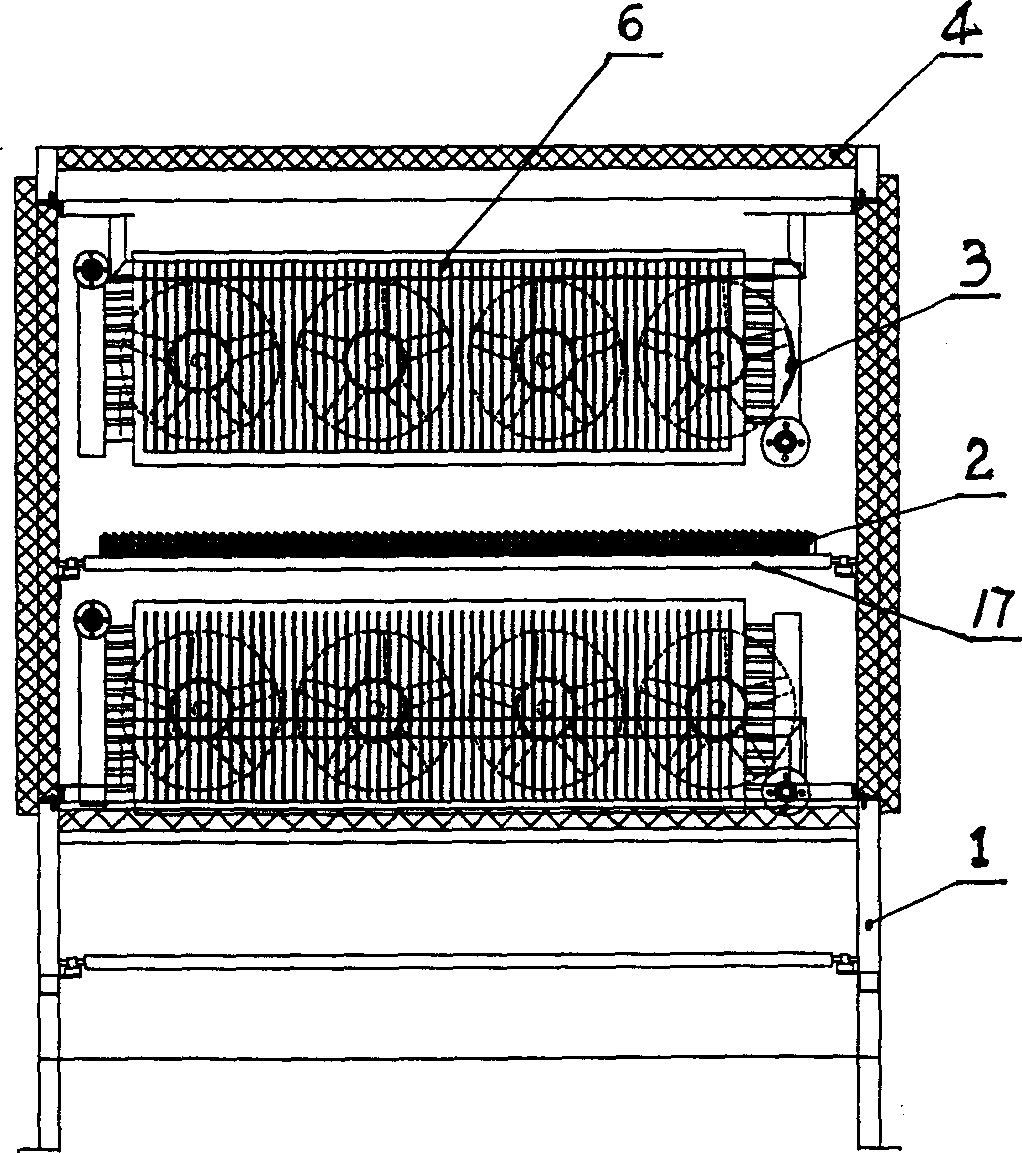

[0009] See attached figure 1 A in the figure is the spreading device, B is the drying section, which is composed of several drying chambers, C is the cooling section, and D is the dampening section, which is composed of several dampening chambers. The tobacco leaves are evenly laid on the mesh belt by the laying device A, and the setting process is carried out through the drying section B, the cooling section C and the dampening section D sequentially with the movement of the mesh belt. The spreading device (see attached figure 2 ) adopts a variable speed belt conveyor 13, a variable speed flat-push scraper 9 and a group of laying rake rollers 14 to work in coordination. The scraper 9 is driven by a timing belt 8, a timing pulley 11 and a double-speed reducer 12. The scraper The swing is controlled by cylinder 10. When the tobacco leaves are continuously conveyed forward by the variable speed belt conveyor 13, the scraper 9 is dragged by the synchronous belt 8 to do a recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com