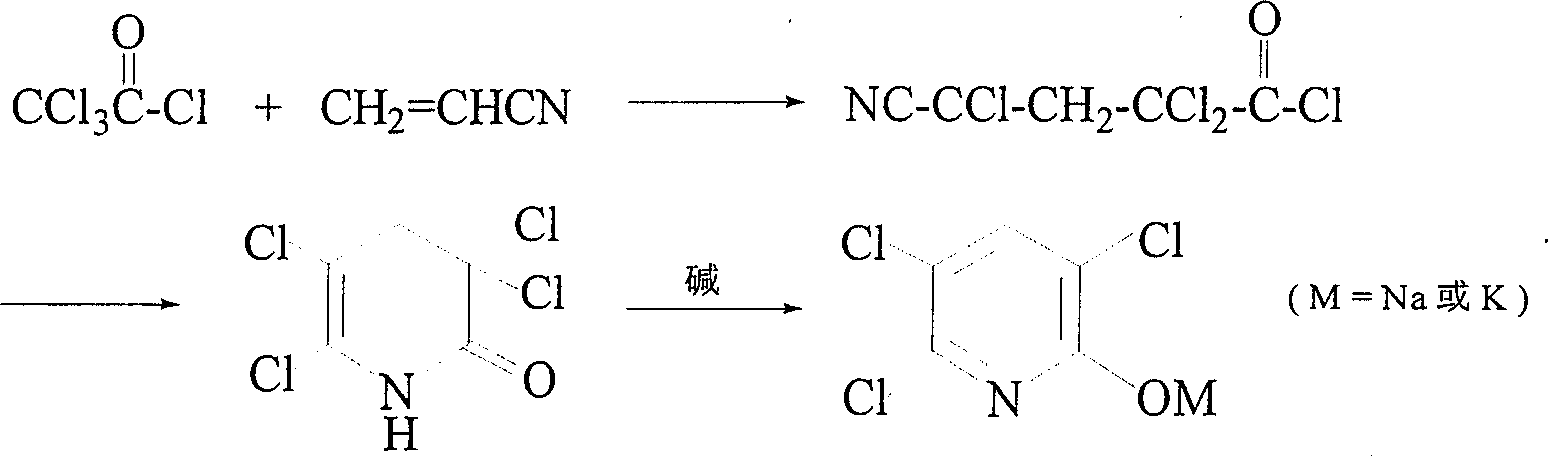

Production method of 3,5,6-trichloro pyridine-2-phenolate

A production method, the technology of triclopyridine, applied in the direction of organic chemistry, etc., can solve the problems of low reaction yield, many types of solvents, and easy pollution of the environment, and achieve the effects of high yield, saving raw materials, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In a 3000L enamel glass reaction kettle, add 1500L p-chlorotoluene, 8.9Kg cuprous chloride, 546Kg trichloroacetyl chloride and 175Kg acrylonitrile in sequence, gradually raise the temperature to 140°C, after 4 hours of reaction, cool down to 40°C, slowly Add 840Kg of 30% sodium hydroxide solution dropwise, then cool, filter and dry to obtain sodium 3,5,6-trichloropyridin-2-ol. The total yield is 63.2%.

Embodiment 2

[0014] In a 3000L enamel glass reaction kettle, add 1500L xylene, 11.4Kg cuprous iodide, 546Kg trichloroacetyl chloride and 191Kg acrylonitrile in sequence, gradually raise the temperature to 135°C, and after 5 hours of reaction, cool the reaction solution to 40°C , slowly add 840Kg30% sodium hydroxide solution dropwise, then cool, filter and dry to obtain 3,5,6-trichloropyridine-2-phenol sodium. The total yield is 62.5%.

Embodiment 3

[0016] In a 3000L enamel glass reaction kettle, add 1500L o-dichlorobenzene, 5.9Kg cuprous chloride, 546Kg trichloroacetyl chloride and 175Kg acrylonitrile in sequence, gradually raise the temperature to 150°C, react for 3 hours, and cool the reaction solution to At 50°C, slowly add an aqueous solution of sodium carbonate dropwise until the pH value of the reaction liquid reaches above 10, then cool, filter and dry to obtain sodium 3,5,6-trichloropyridin-2-ol. The total yield is 63.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com