Method for producing spiral diaphragm pieces

A spiral and diaphragm technology, applied in the field of spiral diaphragm parts, can solve problems such as breakage, poor wrinkle accuracy, wrinkling, etc., to reduce the degree of heating and compression, ease heating/compression conditions, The effect of low bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

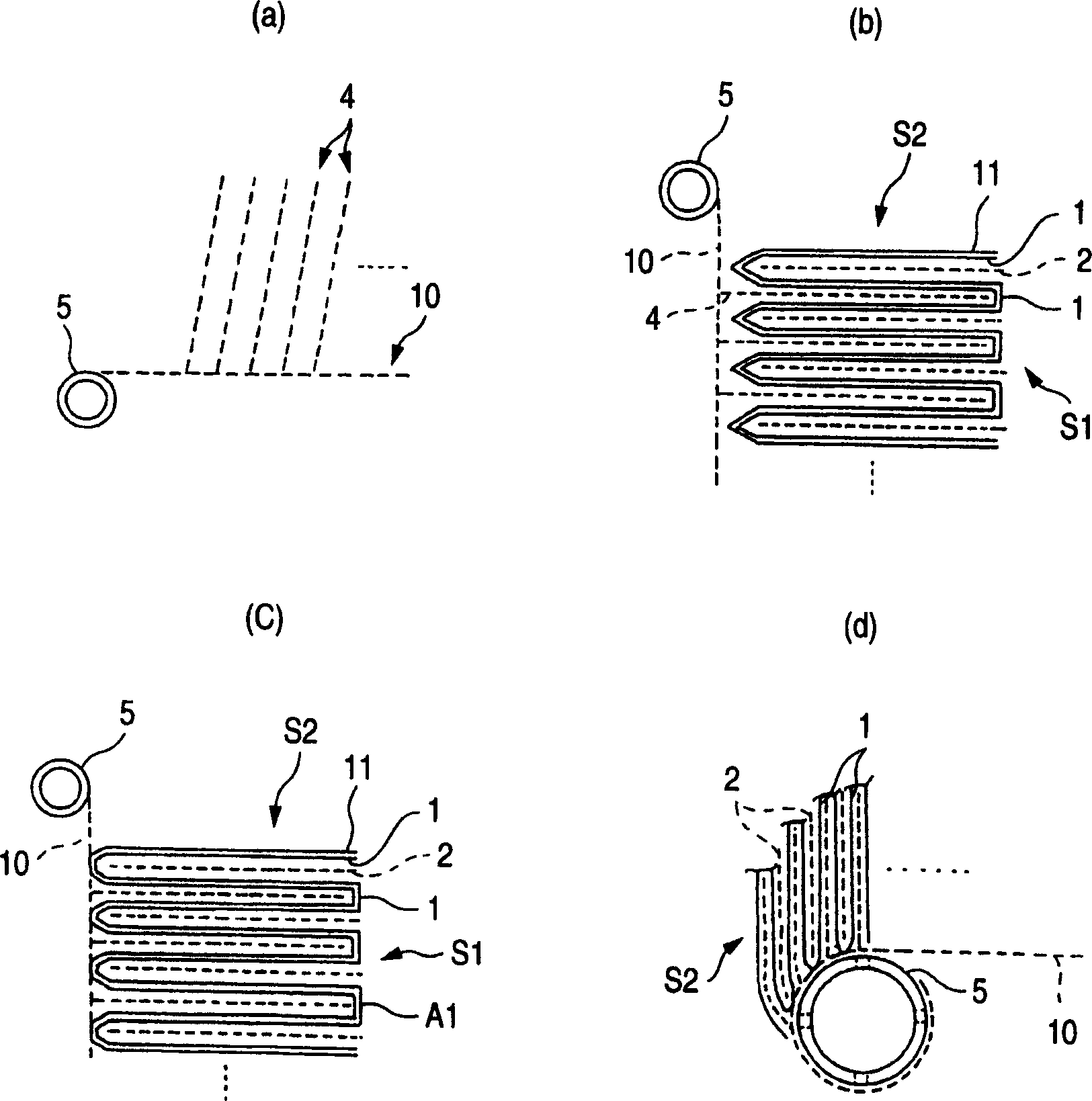

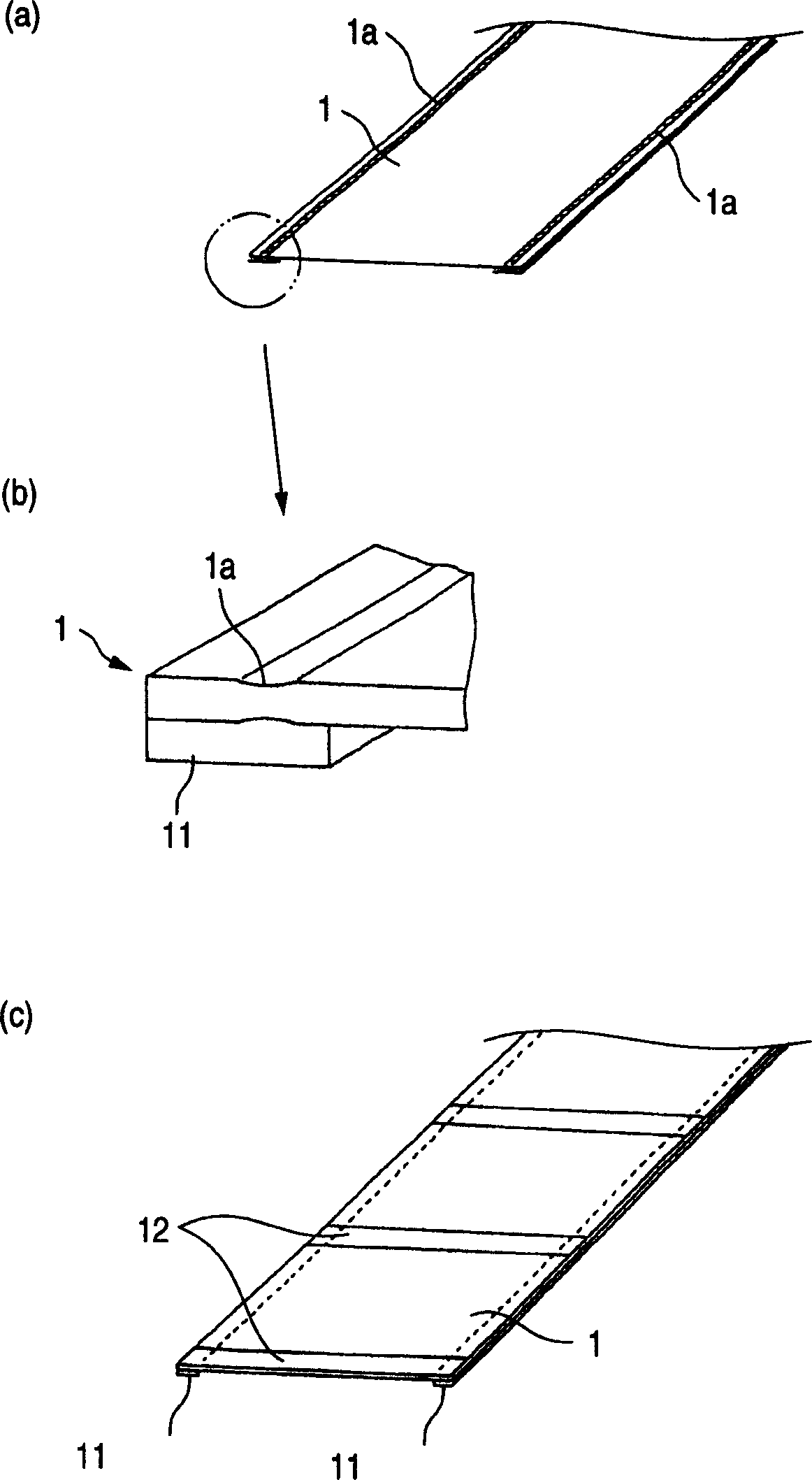

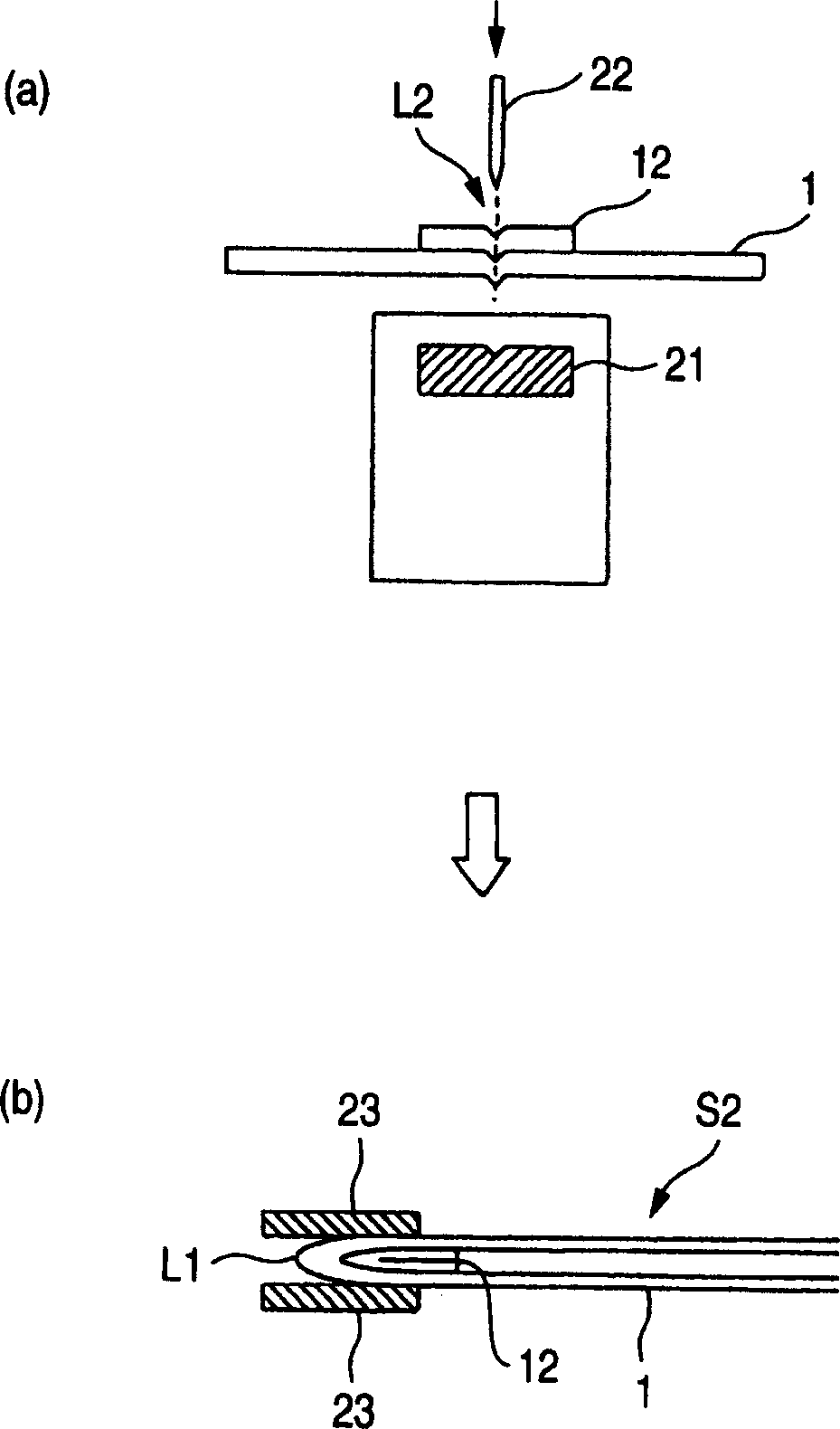

Method used

Image

Examples

example 1

[0080] A 924 mm wide film (NTR-759HR) manufactured by Nitto Denko Co., Ltd. was unwrapped while continuously heat-sealing 5 mm over a width of 10 mm from each side edge. A fusion-bonded tape having a width of 20 mm was applied to the edge of the permeation side of each fusion-bonded portion under a pressure of 0.05 MPa while avoiding wrinkling. Make sure there are no wrinkles. A PET tape No. 31B (manufactured by Nitto Denko Corporation) having a width of 50 mm was attached to the feeding side of the film at the same interval of 750 mm in the length direction while avoiding wrinkling. After applying the tape, a line was formed with a pressure of 200 N on each part where the corrugation was to be formed, using a metal sharp tool with a width of 0.5 mm and a die as a receiving tool. A feed-side channel material made of PP with a width of 924 mm was cut to 750 mm in advance. Alternately fix the cut feed side channel material on the position where the PET tape has been pasted. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com