High-energy static vanadium cell

A vanadium battery, high-energy technology, applied in the field of high energy storage static vanadium battery, can solve problems such as high price and restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

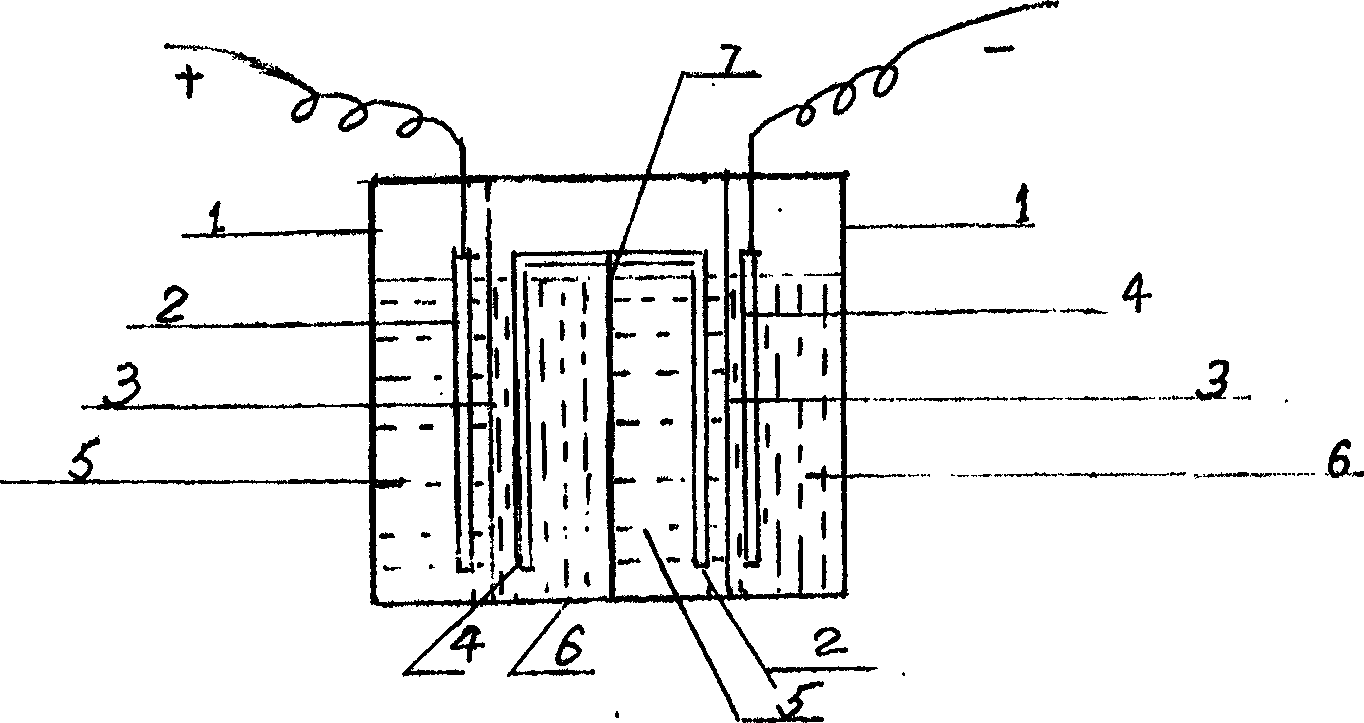

Image

Examples

Embodiment Construction

[0018] 1. Prepare 2.8 mol / liter tetravalent vanadium ion electrolyte (positive electrode electrolyte) and trivalent vanadium ion electrolyte (negative electrode electrolyte) first, put them into the positive and negative electrodes of high-energy static vanadium battery respectively, and then tartaric acid, The stabilizer composed of ethylene glycol and hydrazine hydrate is added to the positive and negative electrolytes according to the proportion of 2% of the total vanadium electrolyte, and then 0.5% activator is added to charge to reach 2.8 moles / liter of pentavalent vanadium ions And divalent vanadium ion electrolyte.

[0019] 2. First prepare 4.5 mol / liter tetravalent vanadium ion electrolyte (positive electrode electrolyte) and trivalent vanadium ion electrolyte (negative electrode electrolyte), put them into the positive and negative electrodes of the high-energy static vanadium battery respectively, and use carboxymethyl The stabilizer composed of cellulose, glycerol a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com