Multi-layer distribution board and mfg method, electronic device and electronic apparatus

A technology of multilayer circuit board and manufacturing method, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, electric solid-state devices, etc., and can solve problems such as disconnection of wiring layers, reduced use efficiency, and unevenness of the upper layer of the inner insulating film. Achieve the effects of avoiding open circuit, uniform film thickness and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

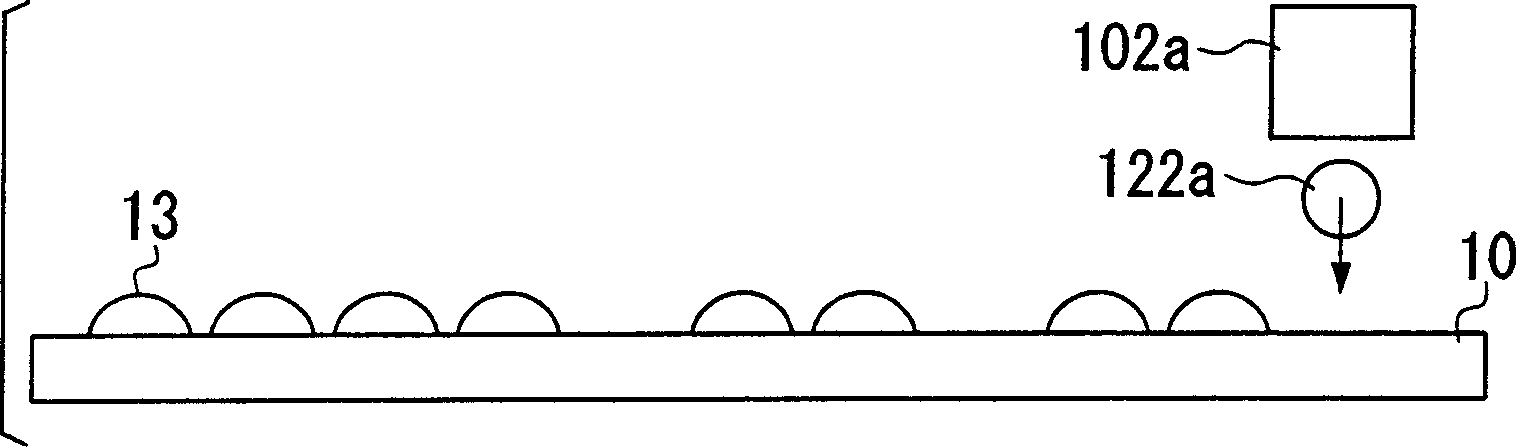

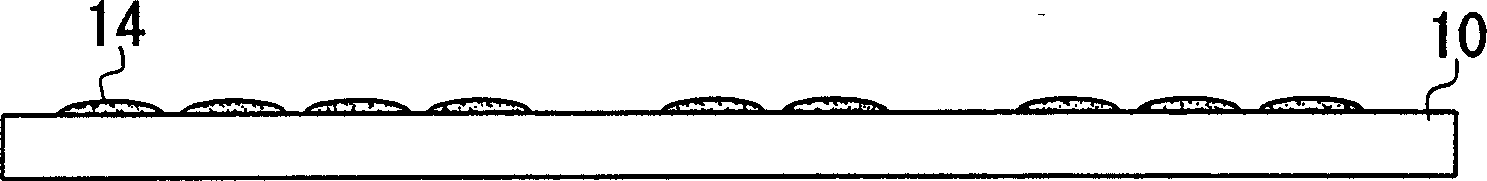

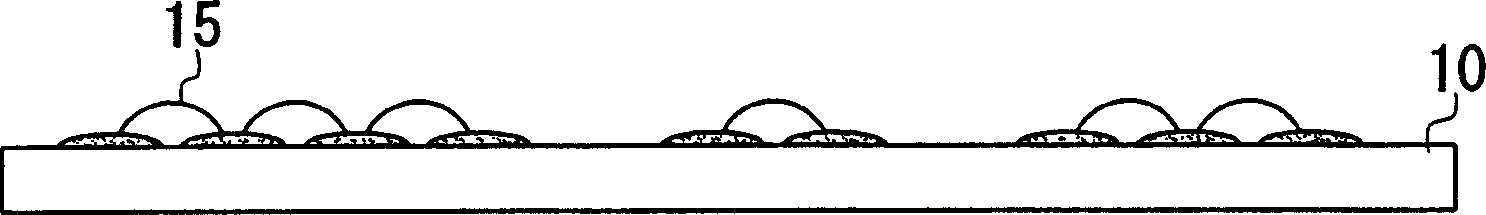

[0077] Figures 1A-3C It is a schematic diagram showing each process of the multilayer circuit board manufacturing method according to the first embodiment of the present invention. Figures 1A-1H Represents various processes from the ink repellent coating process to the process of forming the first circuit pattern (ie, the first wiring layer) and the inner layer conductive pillars. Figure 2A -2H indicates the process of forming the first interlayer insulating film. Figures 3A-3C Indicates that a second circuit pattern (ie, a second wiring layer) is formed. The respective processes of the second interlayer insulating film and the third circuit pattern (ie, the third wiring layer). In the present embodiment, multilayer printed wiring is formed on one surface of the substrate 10 .

[0078] Figure 4A with 4B is a schematic diagram showing a droplet ejection apparatus used in a method of fabricating a multilayer circuit board. Figure 4A is a perspective view showing the g...

no. 2 example

[0143] Image 6 is a schematic diagram showing a step in the method for manufacturing a multilayer circuit board according to the second embodiment of the present invention. In this embodiment, instead of the calculation process of the insulating film formation area in the first embodiment, the measurement process of the insulating film formation area is carried out. Other processes are the same as those of the first embodiment.

[0144] Processes different from those of the first embodiment will be described in detail below. Regarding other processes, only a series of flows of the respective processes of forming a multilayer circuit board will be described. Image 6 in, with Figure 1A to Figure 4B The same parts are given the same reference numerals.

[0145] In the multilayer circuit board manufacturing method of the present embodiment, (i) the ink repelling process to the substrate 10, (ii) the first circuit pattern forming process, and (iii) the inner layer conductive...

no. 3 example

[0162] Figures 8A to 8E It is a schematic diagram showing each step in the method for manufacturing a multilayer circuit board according to the third embodiment of the present invention. In this embodiment, a plurality of inner-layer insulating films are formed, and after the first inner-layer insulating film is formed, each height difference in the upper surface of the first inner-layer insulating film is measured, and the second inner layer is formed according to the measured data. insulating film to make the upper surface of the first inner layer insulating film flat.

[0163] Only the processes different from those of the first and second embodiments will be described in detail below. Regarding other processes, only a series of flows of the respective processes of forming a multilayer circuit board will be described. Figures 8A to 8E , with Figure 1 to Figure 7 The same parts are given the same reference numerals.

[0164] In the multilayer circuit board manufacturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com