Mfg. of ecological building agglutinating material by using carbide slag

A technology for ecological construction and cementitious materials, applied in the field of cement, can solve the problems of rising cost, treatment failure and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

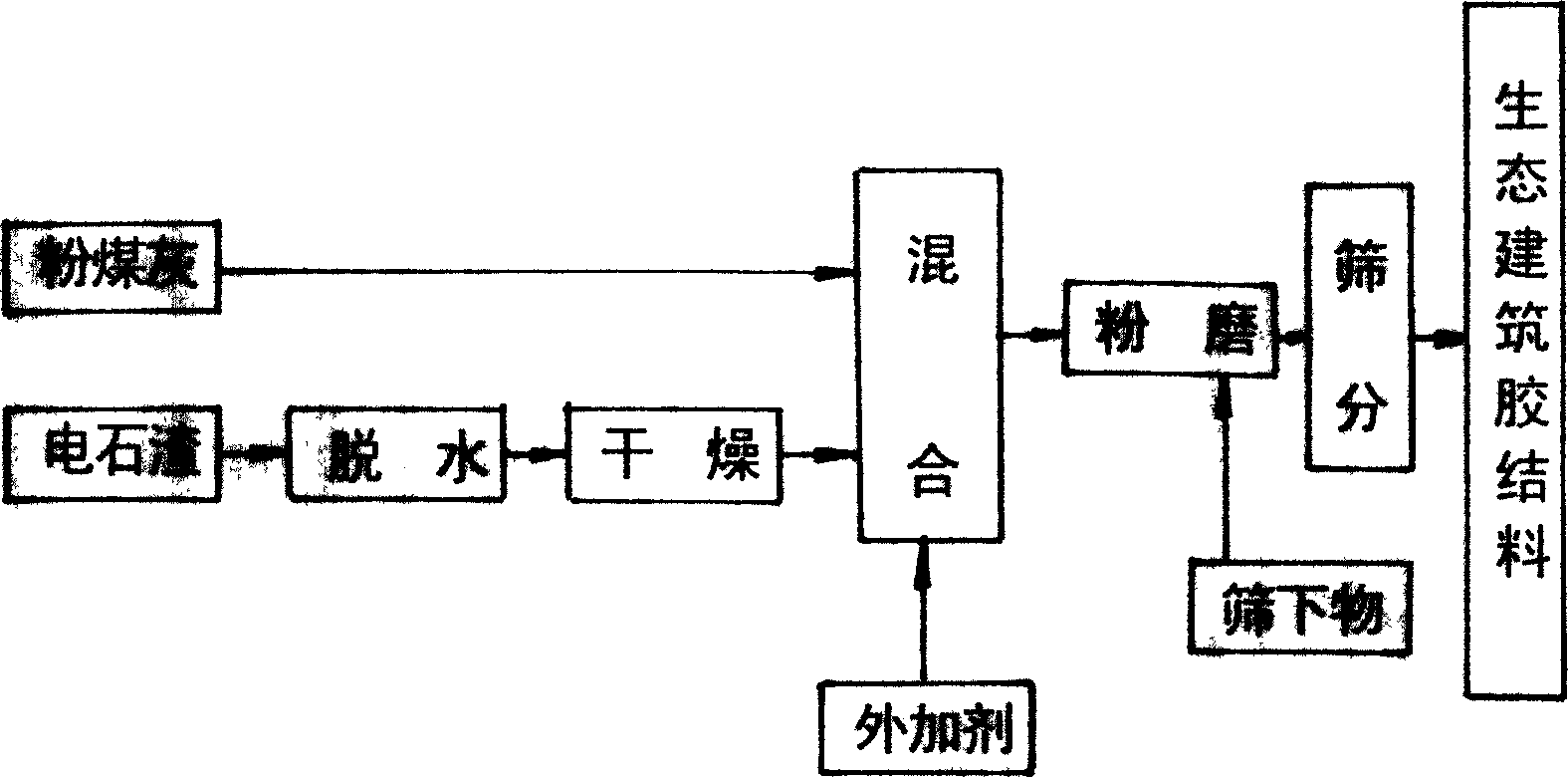

Method used

Image

Examples

Embodiment 1

[0009] The calcium carbide slag slurry with a water content of 90% is dehydrated by sedimentation, mechanical dehydration, and dried in an environment of 70 ° C. After drying, 65 kg of calcium carbide slag powder is mixed with fly ash (dry ash discharge from the flue) or slag (slagging from the bottom of the furnace) 33Kg is mixed with 2Kg of admixture (silicon powder), the mixing ratio should depend on CaO and SiO 2 Depending on the activity and proportion in the respective materials, after grinding and sieving (using a sieve with a sieve hole of 0.8mm), the undersieve is ground and sieved again to form the ecological building cement.

[0010] Components of this example:

[0011] 65Kg calcium carbide slag powder contains 68% CaO (44.2Kg), SiO 2 3% (1.95Kg), other 29% (18.85Kg);

[0012] 33Kg fly ash containing 4% CaO (1.32Kg), SiO 2 51% (16.83Kg), other 45% (14.85Kg);

[0013] 2Kg admixture silicon powder SiO 2 100% (2Kg);

[0014] That is, in 100Kg of raw materials, ...

Embodiment 2

[0017] Carbide slag slurry with a water content of 90% is subjected to sedimentation dehydration, mechanical dehydration, and drying at 90°C. After drying, 56Kg of calcium carbide slag powder, 35Kg of fly ash and 9Kg of admixture (silicon powder) are respectively ground and sieved. After sieving (using a sieve with a sieve size of 0.8mm), the undersieve is ground, sieved and mixed. The mixing ratio should be based on CaO, SiO 2 Depending on the activity and proportion in the respective materials, it becomes the ecological building cement.

[0018] Components of this example:

[0019] 56Kg calcium carbide slag powder contains 71% CaO (39.76Kg), SiO 2 3.21% (1.7976Kg), other 25.79% (14.4424Kg);

[0020] 35Kg fly ash contains 3.9% CaO (1.365Kg), SiO 2 49% (17.15Kg), other 47.1% (16.485Kg);

[0021] 6Kg admixture gypsum powder CaO 100% (6Kg);

[0022] 3Kg silicon powder SiO 2 100% (3Kg);

[0023] That is, in 100Kg of raw materials, the content of CaO is 47.125Kg, SiO 2 2...

Embodiment 3

[0025] The calcium carbide slag slurry with a water content of 90% is dehydrated by sedimentation, mechanical dehydration, and dried in an environment of 120°C. After drying, 60Kg of calcium carbide slag powder is mixed with 34Kg of fly ash and 6Kg of admixture (gypsum powder). After grinding, After sieving (using a sieve with a sieve hole of 0.8 mm), the undersieve is ground and sieved to become the ecological building cement.

[0026] Components of this example:

[0027] 60Kg calcium carbide slag powder containing 60% CaO (36Kg), SiO 2 4% (2.4Kg), other 36% (21.6Kg);

[0028] 34Kg fly ash contains 3.8% CaO (1.292Kg), SiO 2 52% (17.68Kg) other 44.2% (15.028Kg);

[0029] 6Kg admixture gypsum powder CaO 100% (6Kg);

[0030] That is, in 100Kg of raw materials, the content of CaO is 43.929Kg, SiO 2 20.08Kg, others 36.028Kg.

[0031] The product of the present invention has the advantages of soft appearance, fine touch, high late strength and good internal quality, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com