Thermosetting adhesive

An adhesive, thermosetting technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of reducing the fluidity, difficulty, and reduction of adhesive strength of reactive hot melt adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

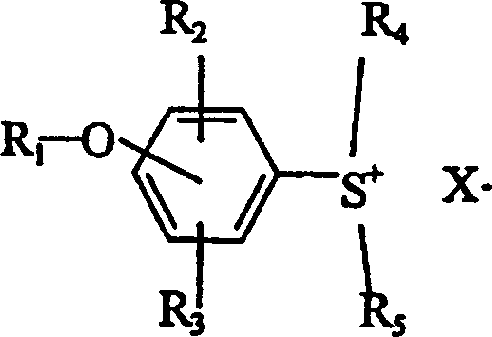

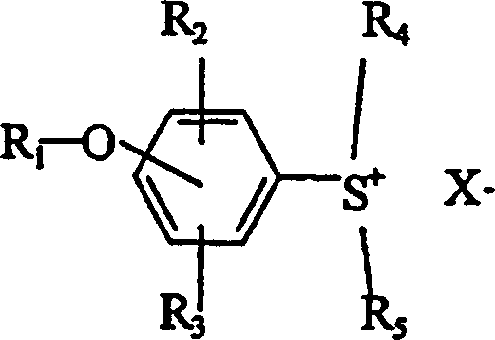

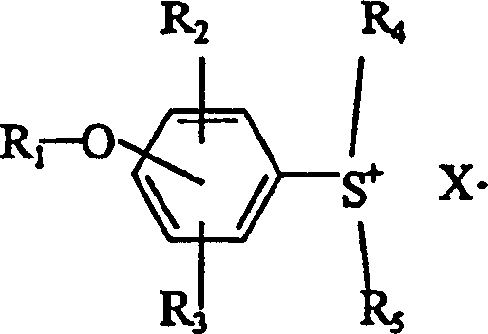

[0030] The preparation of sulfonium salts of cationic polymerization catalysts is generally as follows. Sulfonium salts containing methylsulfate ions can be synthesized by reacting alkyl sulfates with the corresponding 4-substituted hydroxyphenyl alkyl sulfides. Next, it is anion-exchanged with a predetermined double salt to obtain the desired sulfonium salt in high yield. A sulfonium salt was commercially provided by Sanshin Kagaku Kogyo (KK) instead of the manufacture described above, which will be described later in the Examples.

[0031] The adhesive compositions of the invention described above can be used in the form of reactive hot melt film adhesives. The thickness of the film adhesive is preferably 0.001-5 mm, more preferably 0.005-0.5 mm. Due to the uniform cross-linked structure established in the thickness direction, the operation is convenient and the reliability is also high.

[0032] Film adhesives were produced by the method described below. First, the adhes...

Embodiment

[0052] The present invention will be described in detail in the following examples, but the present invention is not limited to these examples.

[0053] 1. Manufacture of film adhesive

[0054] The components in the proportions shown in Table 1 were kneaded at 120°C for 5 minutes to prepare an adhesive composition. Next, a pair of polyethylene terephthalate films (hereinafter referred to as "PET" films) having a length of 1 m, a width of 15 cm, and a thickness of 100 μm were prepared, sandwiching the prepared adhesive composition therebetween. The assembly was then passed through a knife-shaped gap and heated to 150°C to shape it into a 100µm thick film precursor. These film precursors were colorless and transparent, except for the film product precursor of Comparative Example 3, which was yellow.

[0055] In the next step, the film precursor will be irradiated with an electron beam accelerated at 200KV to obtain a film adhesive, and the absorbed dose at this time is 150kGy....

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com