Document transported typed scanning mechanism

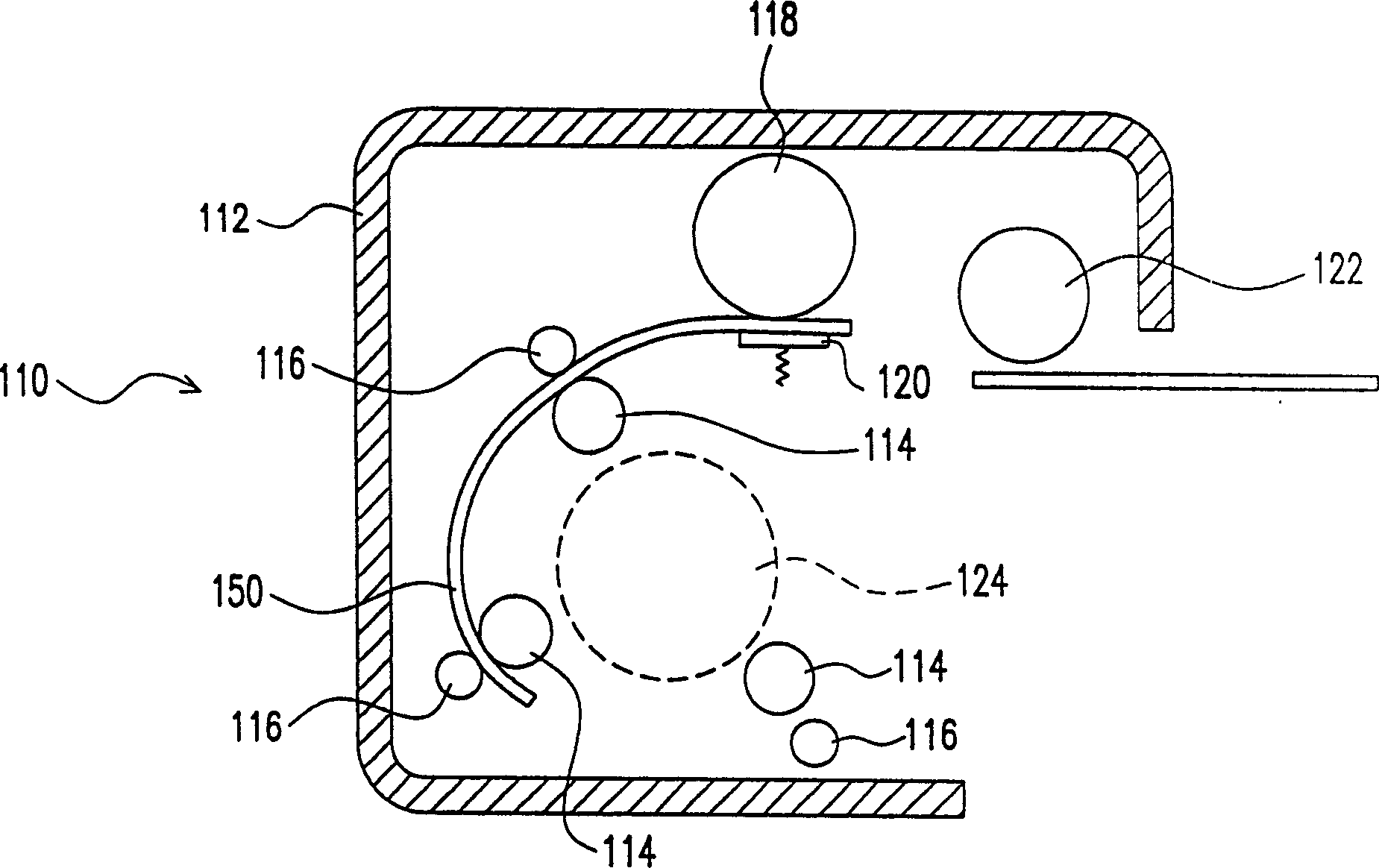

A document transmission and scanning mechanism technology, applied in the direction of electrical components, image communication, etc., can solve the problems of high height of the document transmission mechanism 110, difficult to design, complicated mechanism design and coordination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

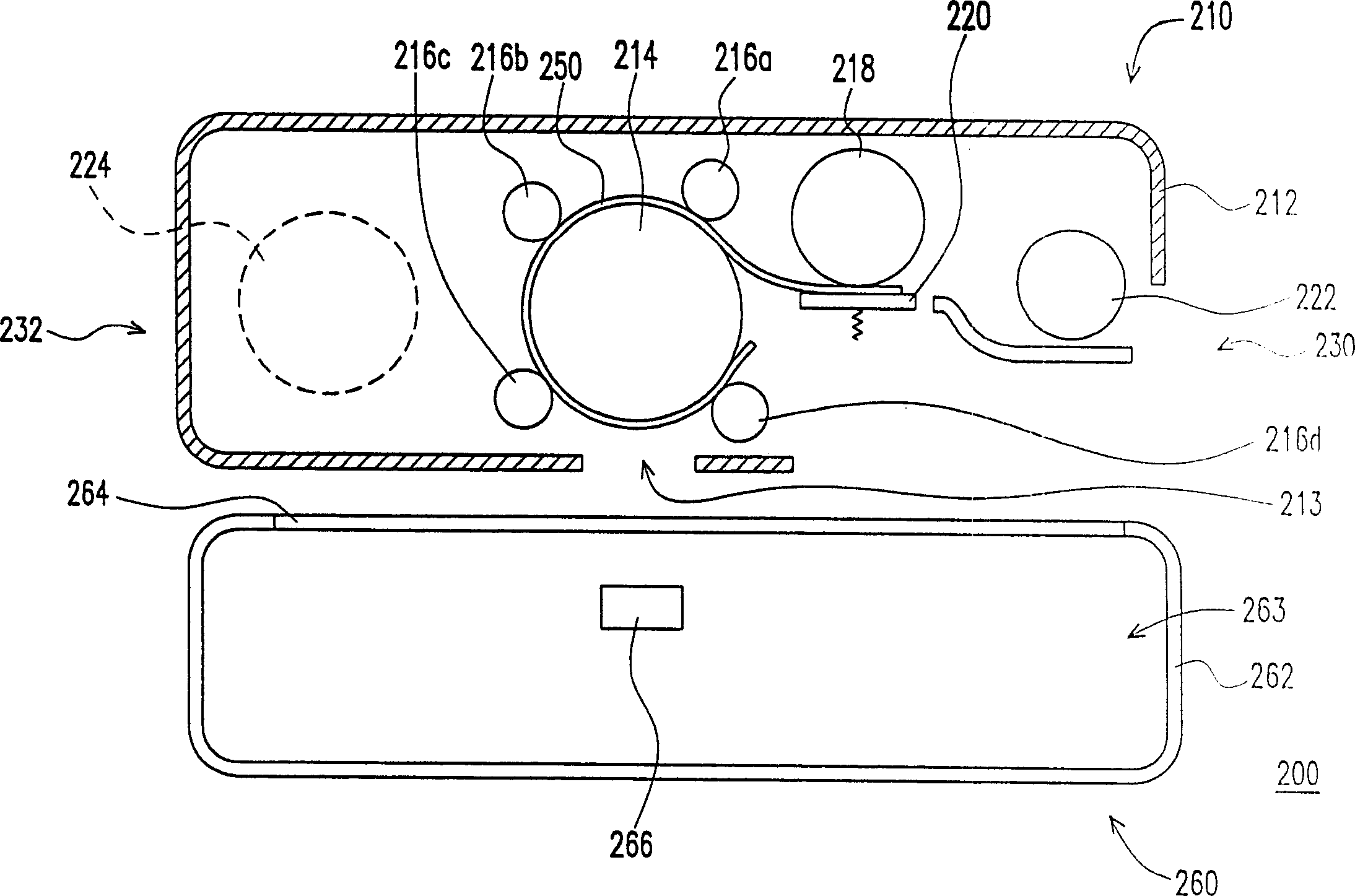

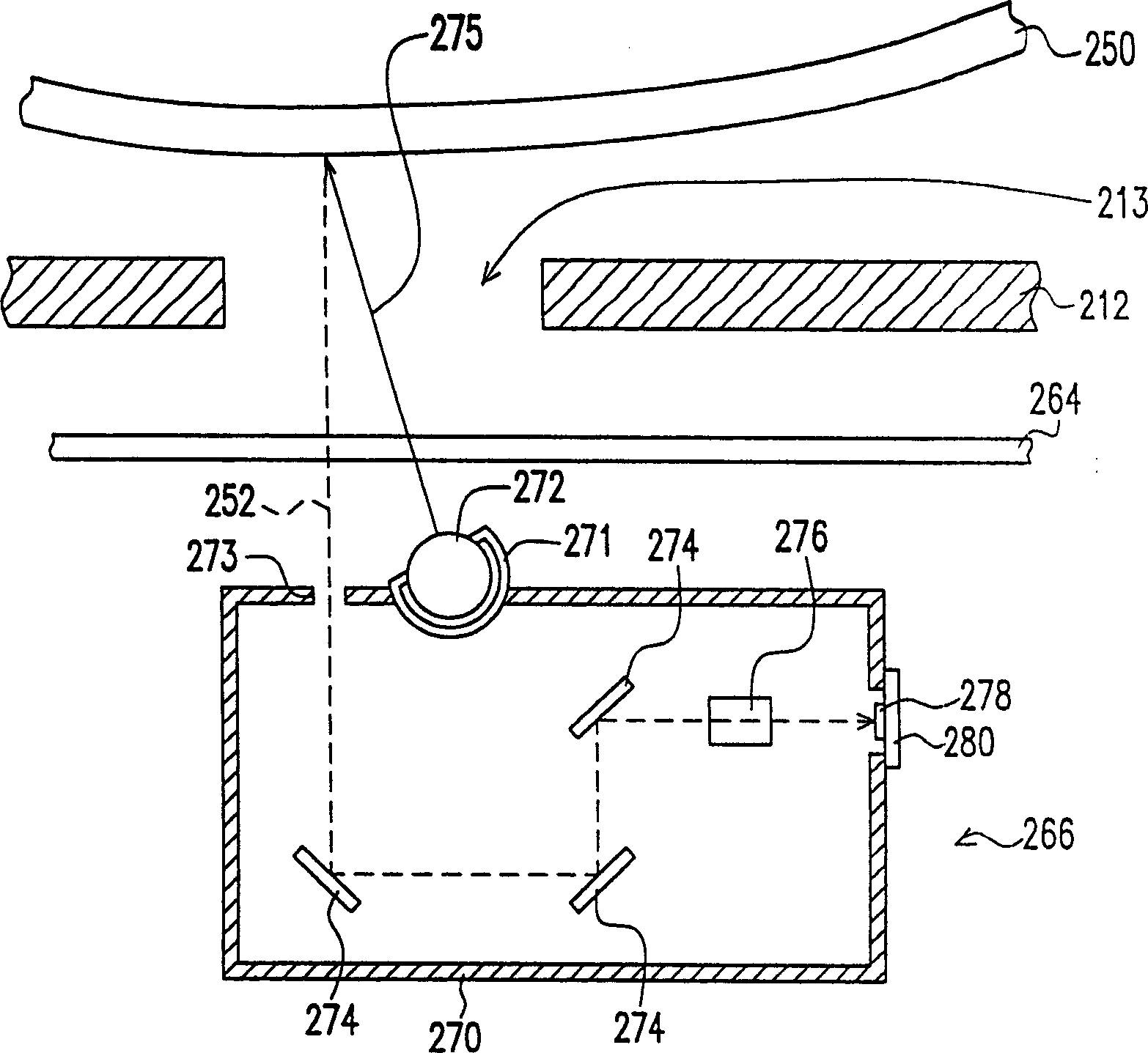

[0072] Please refer to figure 2 , which is a structural schematic diagram of a file transport scanning mechanism according to a first preferred embodiment of the present invention. The file transfer type scanning mechanism 200 includes a file transfer mechanism 210 and a scanner 260, the file transfer mechanism 210 is located on the scanner 260, and the file transfer mechanism 210 is used to transfer a document 250, and the scanner 260 is used to scan and transfer to the file Document 250 in transport mechanism 210 .

[0073] The document delivery mechanism 210 includes a document delivery mechanism housing 212, a transport roller 214, four subordinate rollers 216a, 216b, 216c, 216d, a split roller 218, a split plate 220, a file loading roller 222 and a motor 224 . The file transfer mechanism 210 has a first side 230 and a corresponding second side 232, the document 250 enters the file transfer mechanism 210 from the first side 230, and the motor 224 is located inside the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com