Surface discharged colour plasma display screen unit structure

A plasma and surface discharge technology, used in discharge tubes, electrical components, gas-filled discharge tubes, etc., can solve the problems of low image resolution, low luminous efficiency, and high power consumption, and achieve improved luminous efficiency, vivid colors, The effect of reducing wall loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

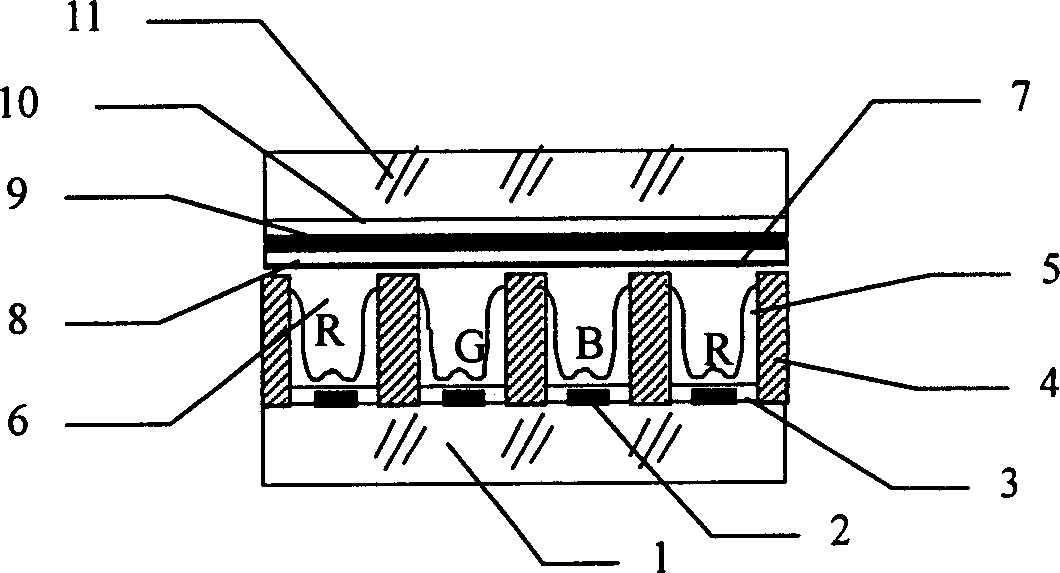

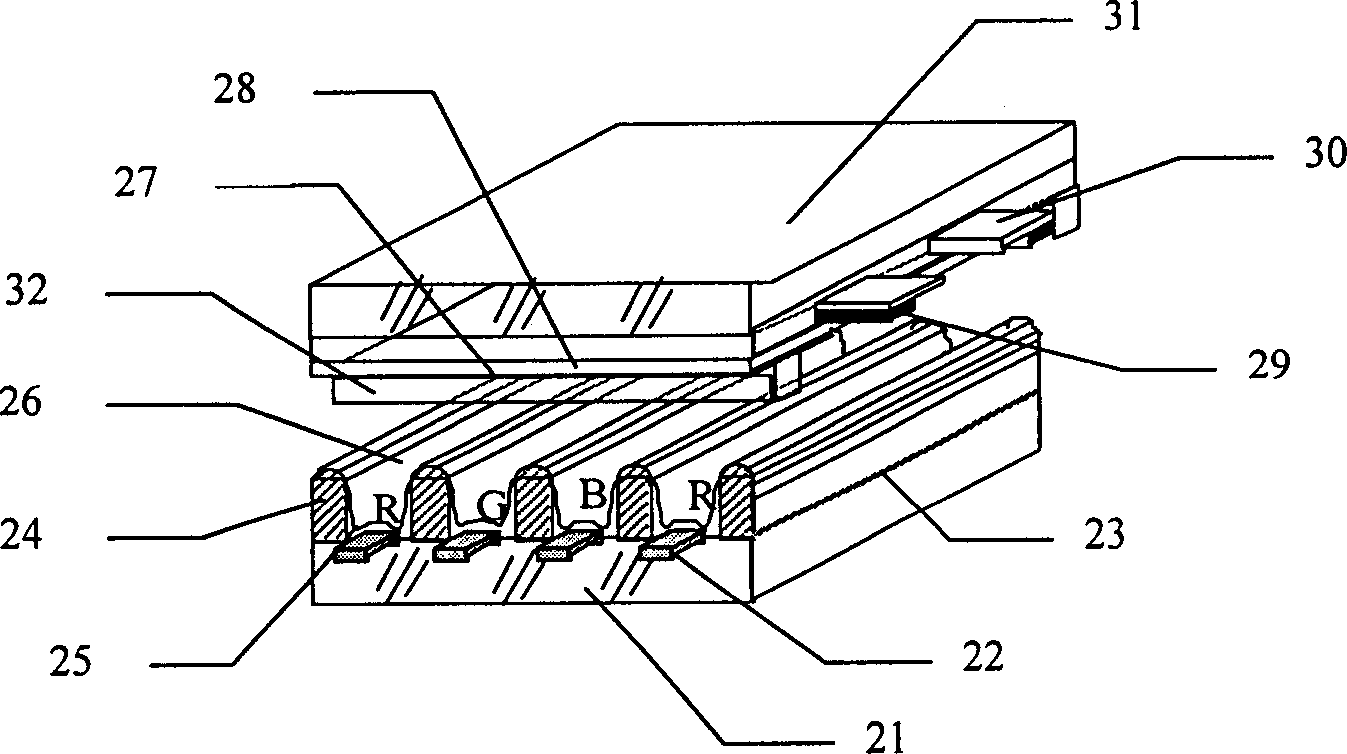

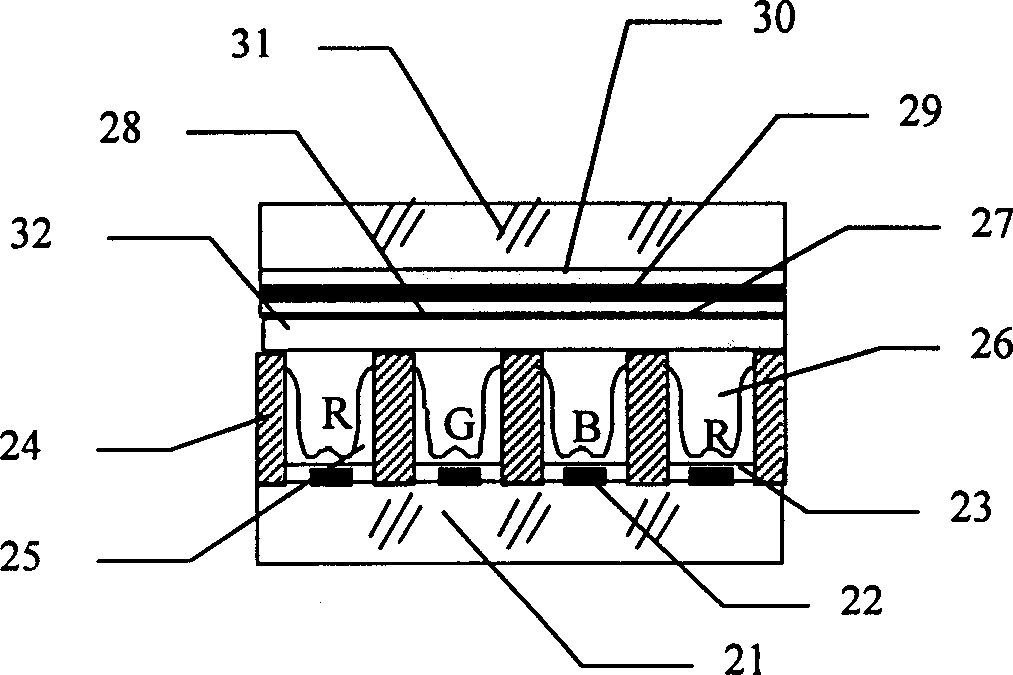

[0046] Such as figure 2 , image 3 As shown, the rear plate is composed of a rear substrate 21, an address electrode 22, a white medium 23, a barrier strip 24, a fluorescent powder 25 and a mixed gas 26, wherein the address electrode 22 is printed on the rear substrate 21, and the address electrode 22 is printed on the rear substrate 21. Print a layer of white medium 23 on the top of the white medium 23, make barrier strips 24 by sandblasting on the surface of the white medium 23, and print three primary color phosphors 25 in the corresponding barrier strips 24; 30. Composed of BUS electrodes 29, transparent medium 28, magnesium oxide cathode film layer 27, and black barrier strips 32, wherein the T-shaped scan-sustain electrode pair 30 is etched on the front substrate 31, and printed on the T-shaped scan-sustain electrode pair 30 BUS electrode 29, print transparent medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com