Ethylene gas adsorbent, method of controlling ethylene gas concentration and ethylene gas sensor

A gas sensor and gas concentration technology, applied in the ethylene gas concentration control method and device, ethylene gas sensor for detecting ethylene in gas, packaging materials or packaging materials, freshness or control of ripening of plants and fresh products, can solve the problem Issues that have not yet been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

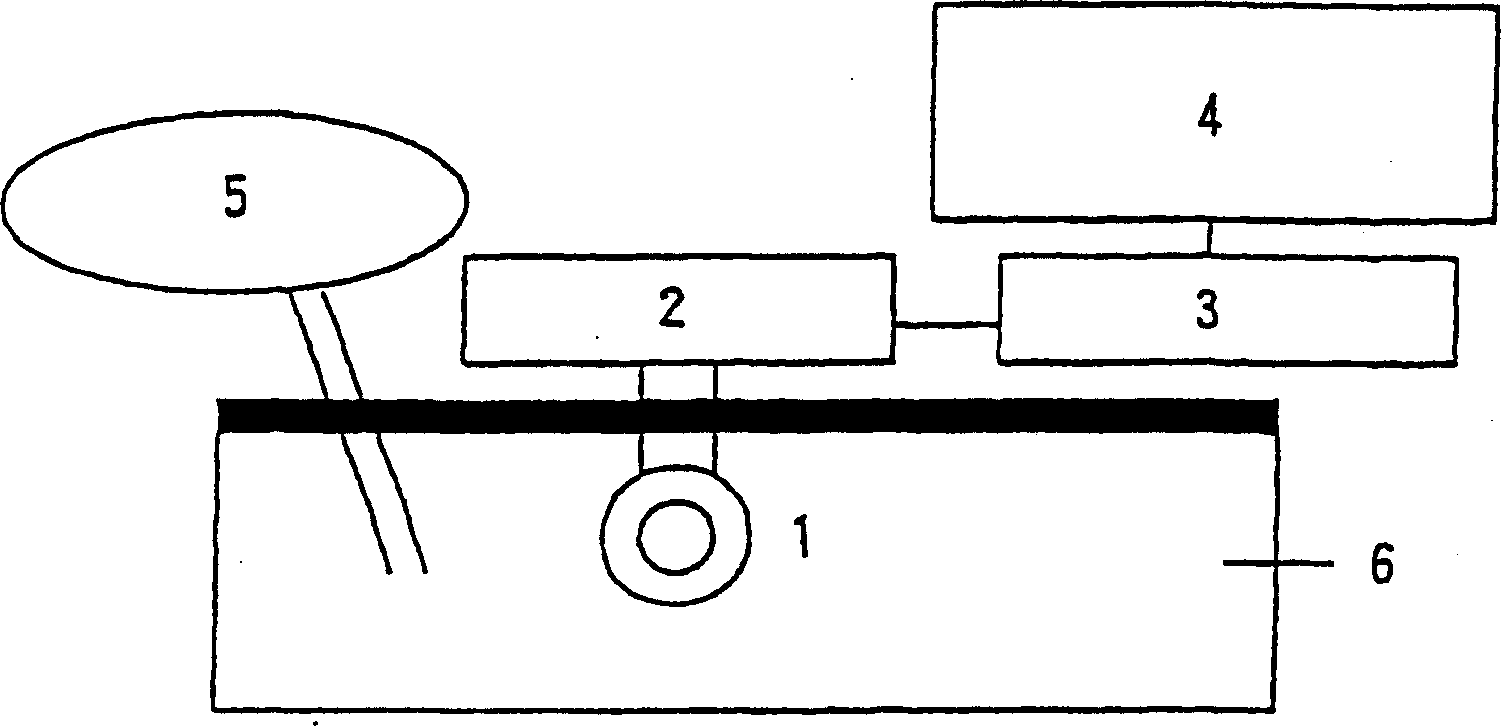

[0089] (manufacturing of sensors)

[0090] Bamboo vinegar liquid is prepared by adding the powder of Mengzong bamboo into the basket and drying at 300°C and 5 atmospheres for 4 hours. 0.2 microliters of this bamboo vinegar solution was poured on the electrodes of the crystal vibrator, and dried for 24 hours to prepare a sensor.

[0091] (Ethylene gas adsorption test)

[0092] The sample thus obtained was inserted into an airtight container in which the concentration of ethylene gas was maintained at a constant concentration of 150, 300, and 800 ppm for 100 seconds, and released to the atmosphere. This assay was performed 3 times.

[0093] (Test method of adsorption capacity)

[0094] The adsorption amount of ethylene gas was measured by the Quartz Crystal Microbalance method (QCM method). The QCM method refers to a method that utilizes the change in the natural vibration number of a crystal oscillator as the mass attached to the electrode changes. If a small amount of sub...

Embodiment 2

[0100] In Example 2, an ethylene gas adsorbent and a sensor made of a composite film using a gel-forming substance having an amino group are shown.

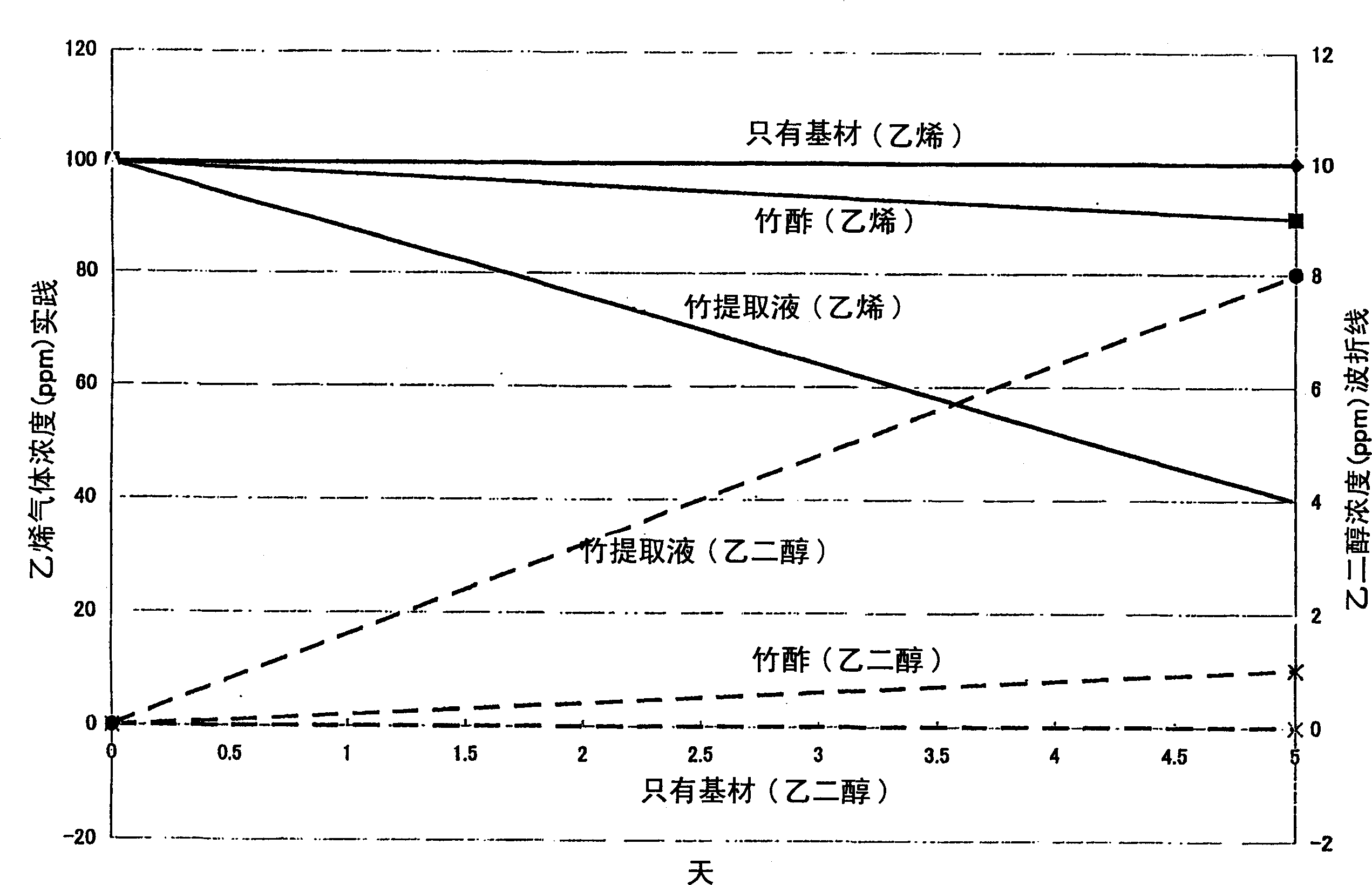

[0101] Before pouring bamboo vinegar liquid on the crystal vibrator, polyallylamine hydrogen chloride (PAH) is used as a binder, and bamboo vinegar liquid is poured on it to make a composite film of PAH and bamboo vinegar liquid. First, the crystal vibrator is treated with KOH to be hydrophilic, and 0.2 microliters of PAH solution is poured, and it is naturally dried for 24 hours to form a thin film. Then, pour 0.2 microliters of bamboo vinegar liquid, carry out 24 hours of natural drying, manufacture composite film. Put the manufactured composite film, PAH single film and crystal vibrator with bamboo vinegar liquid single film into a closed container with ethylene concentration of 200ppm, and observe the reaction of adsorption and desorption. result in Figure 5 Indicated. exist Figure 5 In , the vertical axis represents th...

Embodiment 3

[0103] In Example 3, an ethylene removal test from apples is shown.

[0104] Two cubic acrylic boxes with a side length of 200 mm were used in which the apples were placed. In one box, 50 g of the biodegradable resin foam to which 30 cc of bamboo vinegar solution was attached was placed around the apples, and nothing was placed in the other box. A fan for system air circulation is installed in the upper part of the box.

[0105] The gas detection tube was used to measure the ethylene gas concentration in the box from the beginning of the test to 192 hours, and the results were in Image 6 Indicated. The ethylene gas concentration inside the box, produced by ethylene produced from apples, rose to 100 ppm in the absence of bamboo vinegar. On the other hand, in the presence of bamboo vinegar, the ethylene concentration was suppressed at 5 ppm. The concentration difference is 20 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com