Organic fertilizer fermentation upender

An organic fertilizer and turning machine technology, which is used in the preparation of organic fertilizers and organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems that the fertilizer pile cannot be too high, the oxygen supply is insufficient, and the odor is generated. The effect of good throwing effect, compact structure and lower processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

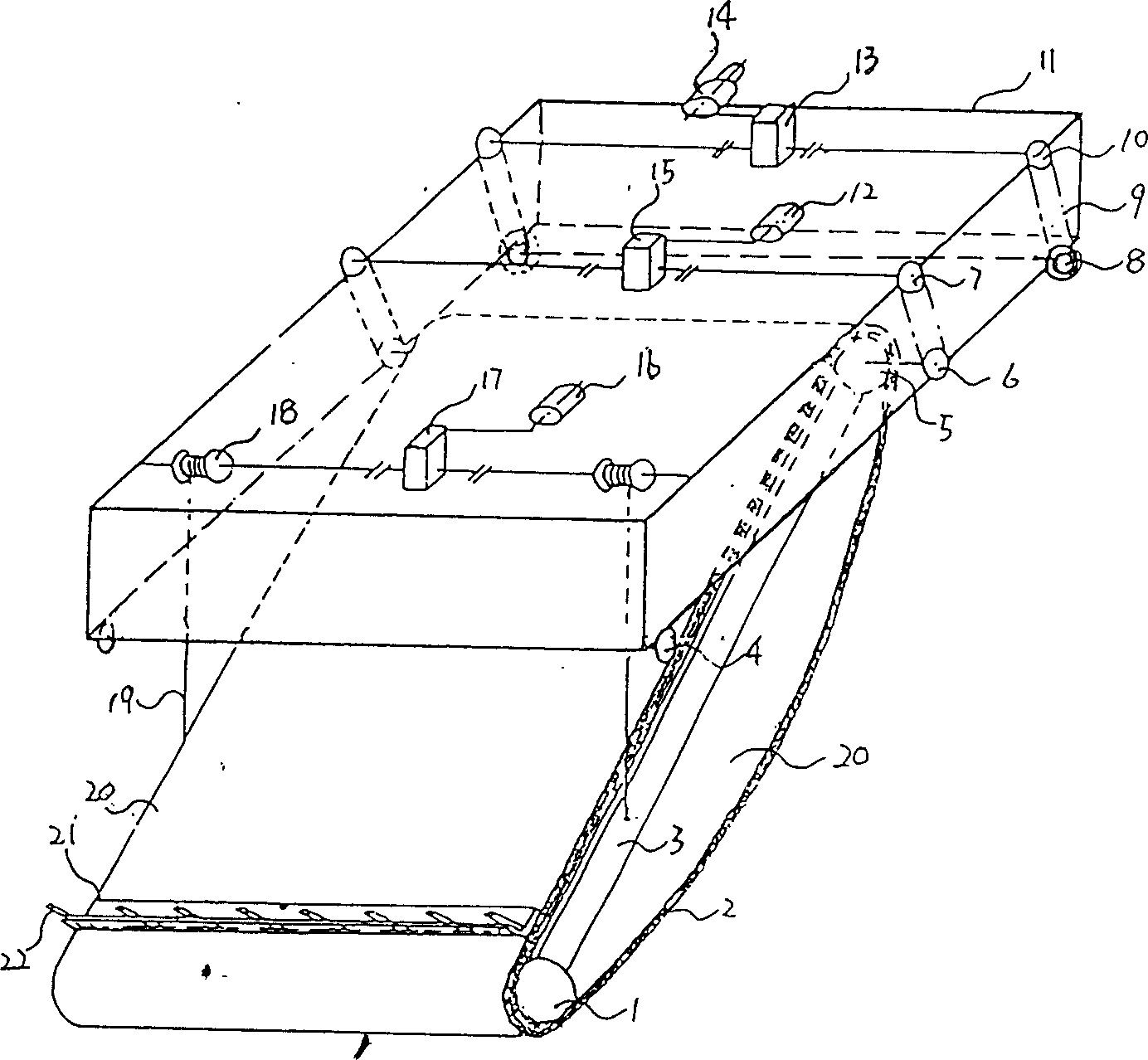

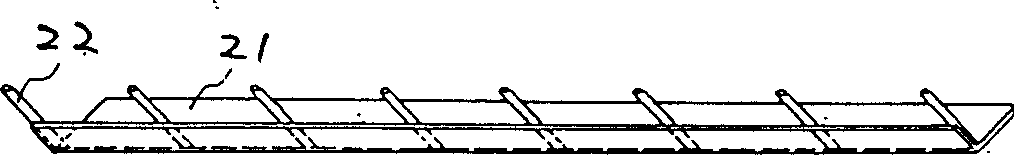

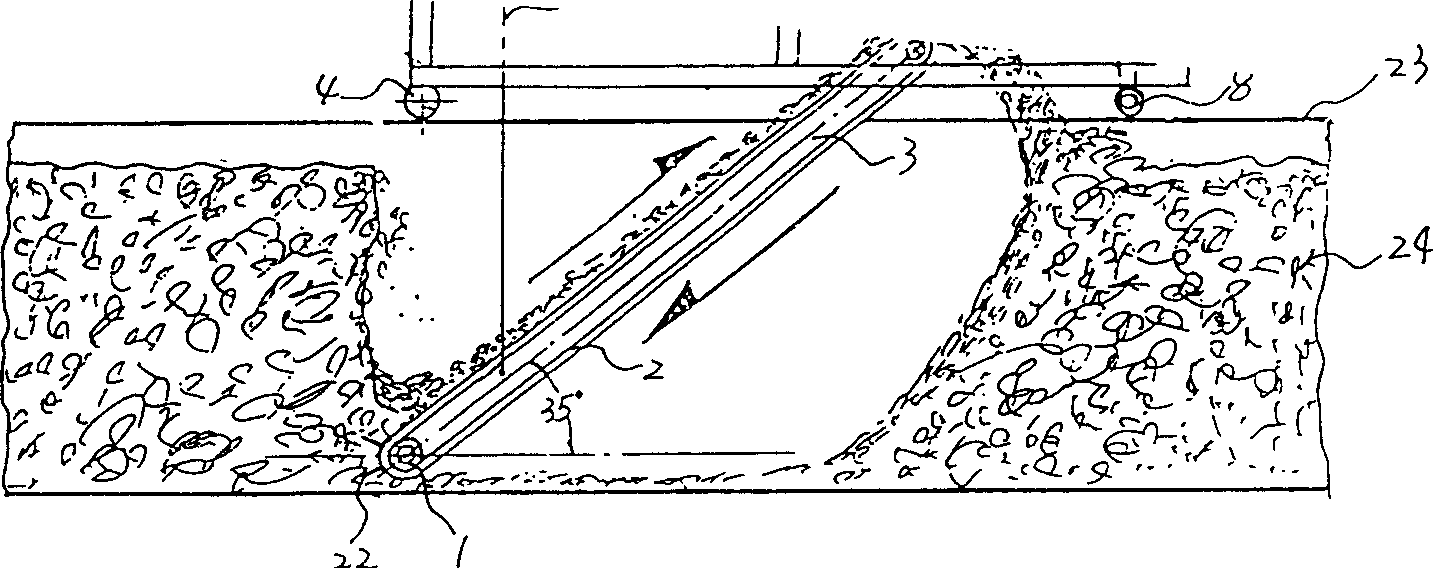

[0020] A kind of embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0021] In the structure as shown in the figure, the shape of the electric trolley 11 is rectangular, and the traveling wheels are arranged at the lower end of the electric trolley, wherein the rear traveling wheels 8 are driving wheels, and the front traveling wheels 4 are passive wheels.

[0022] Three groups of speed-regulating motors are arranged in the electric trolley: the commercially available electromagnetic speed-regulating motor 14 drives the sprocket 10 at both ends of the electric trolley coaxial with the speed reducer through the reducer 13, and the sprocket and the rear traveling wheel are connected by a chain 9 connect. The rear driving wheel obtains power from the electromagnetic speed-regulating motor through a chain, and serves as a driving wheel of the electric driving vehicle to drive the electric driving vehicle to run on the track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com