Stator resin trickling technique and resin trickling device

A technology of dripping paint and stators, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of health hazards for operators, large amount of impregnated paint, and pollution of paint dripping machines, etc., so that there is no fire hazard, The effect of saving the amount of paint used and not causing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

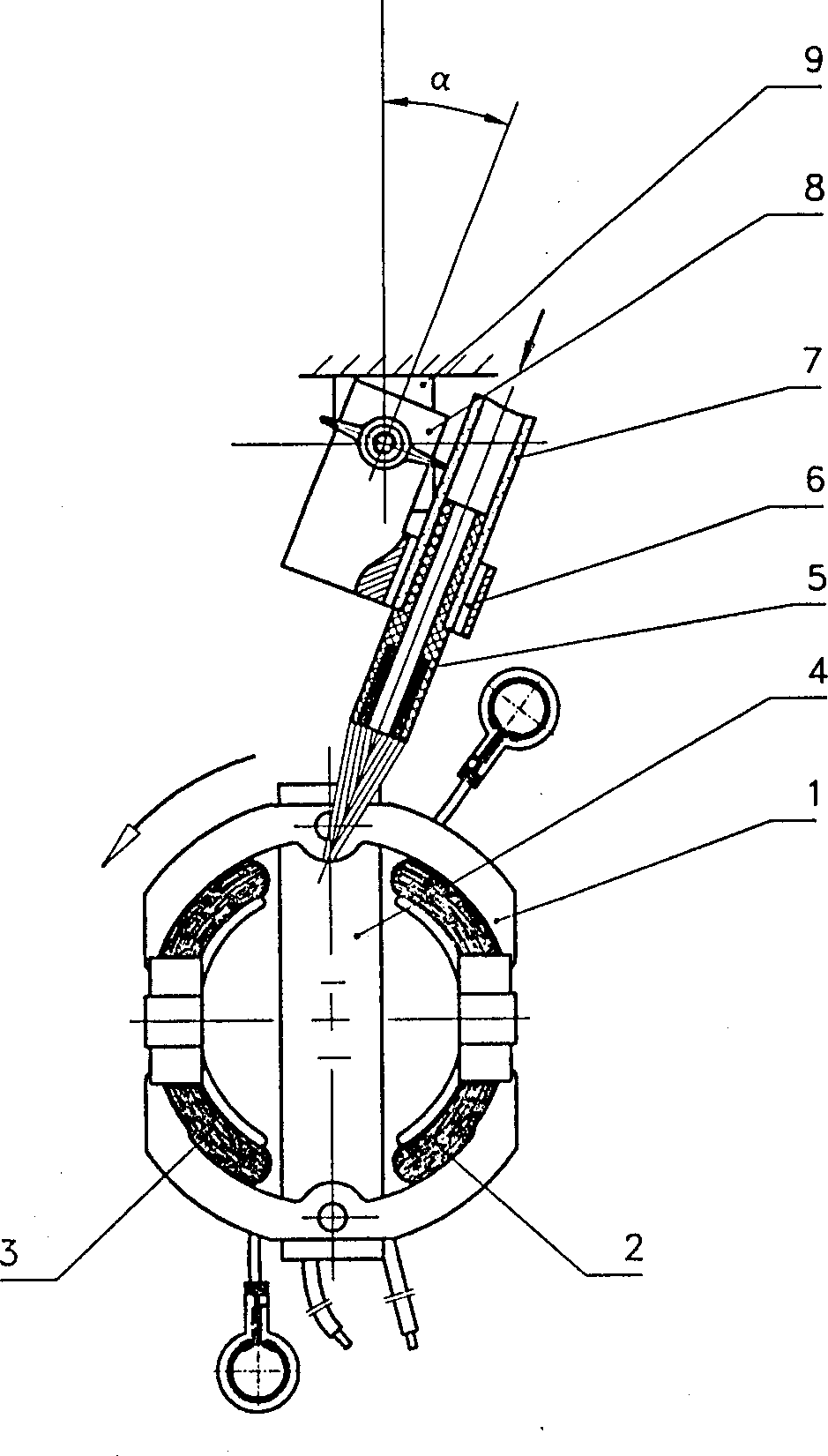

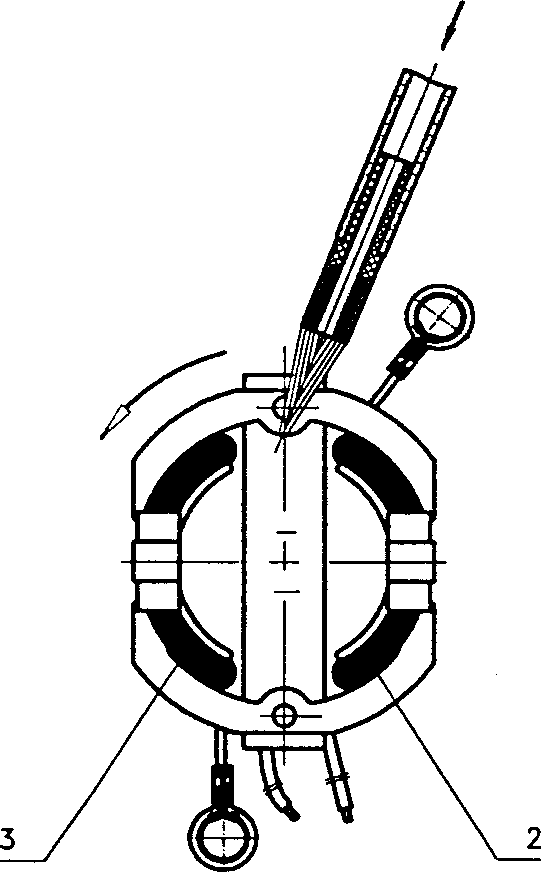

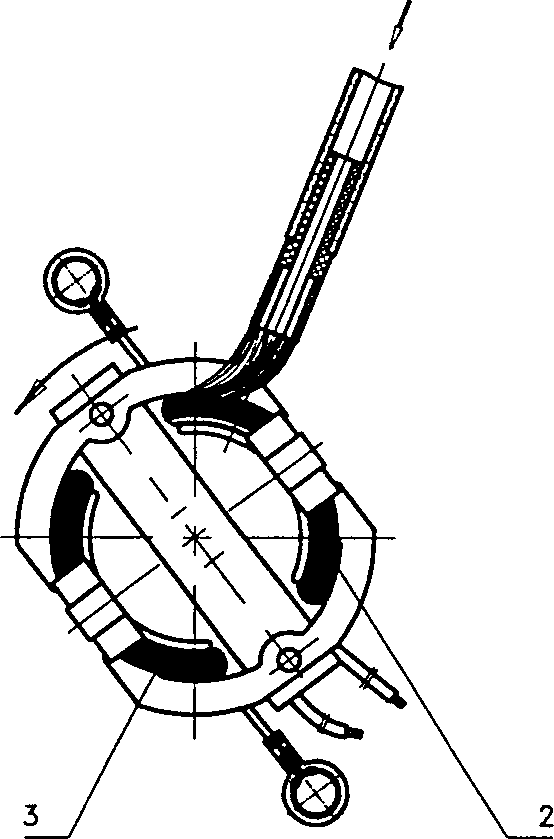

[0025] Such as Figure 7 Shown is the structure diagram of the fixture, which is composed of handle 13, support frame 14, and positioning pin 15. The handle 13 and support frame 14 are processed with Q235 steel. The handle 13 is welded on one side of the support frame 14 and processed with 65Mn steel. Form two locating pins 15, and then weld the two ends on the other side of the support frame 14, insert the locating pins 15 on the fixture 4 into the mounting holes at both ends of the stator 1, as Figure 8 , Figure 9 As shown, the clamp 4 clamps the stator 1, which not only achieves the purpose of fixing, but also makes the stator 1 rotate.

[0026] Such as Figure 8 As shown, it is a structural diagram of the paint dripping head, which is made up of a hairbrush 10, an outer tube 11, and an inner tube 12. The hairbrush 10 is made of a polytetrafluoroethylene material, and is processed into an outer tube 11 with a hard polytetrafluoroethylene material 1. Inner tube 12, even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com