Apparatus for cleaning-out deposited sludge in fluid pool

A technology for sludge and running water, which is applied in waterway systems, water supply devices, cleaning sewer pipes, etc., can solve the problem of increasing vehicles and achieve high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

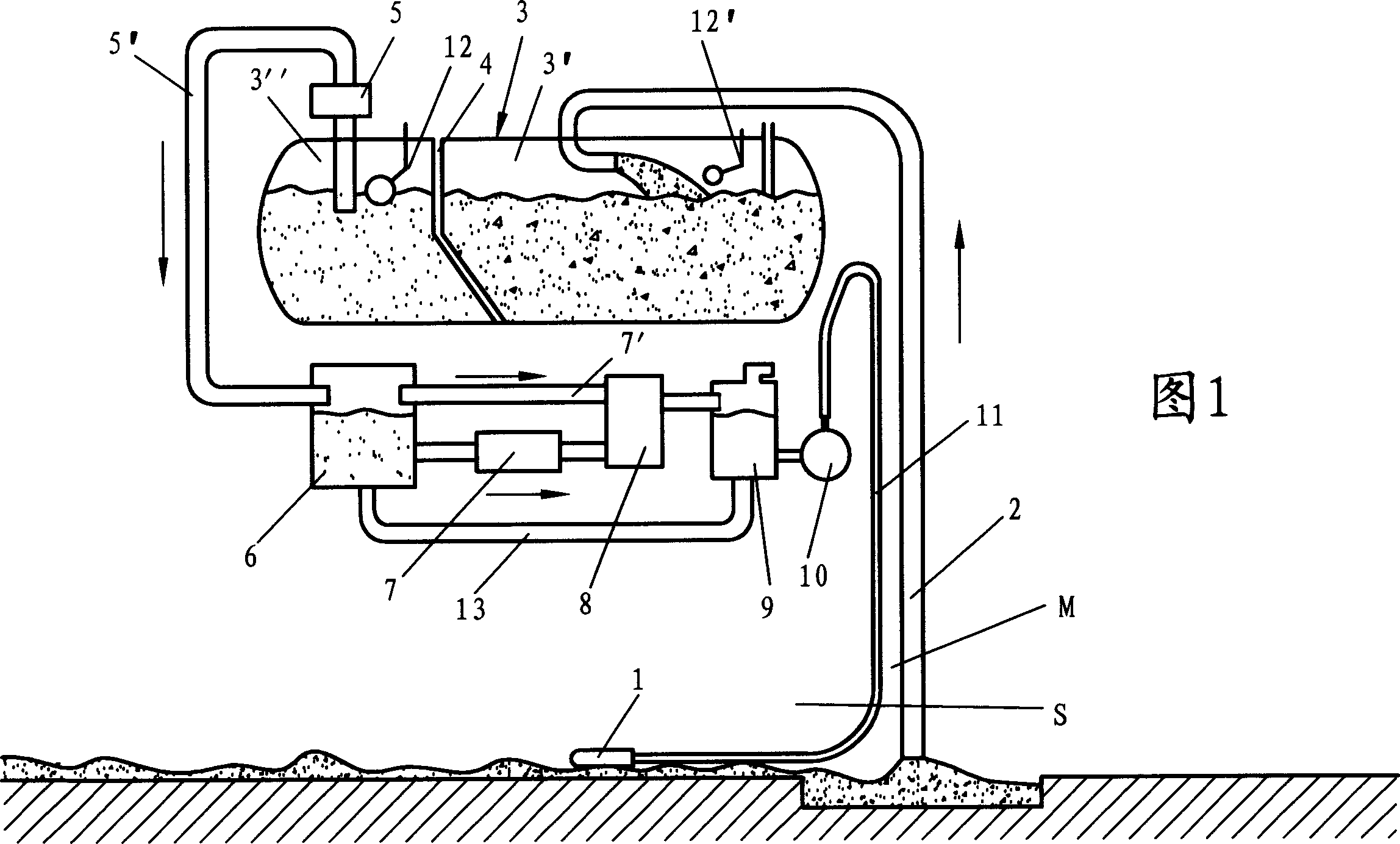

[0008] As shown in Figure 1, the sedimentation sludge recovery tank 3 is divided into the sedimentation sludge chamber 3 ' on the right side and the water chamber 3 " on the left side by the filter partition 4. The filter partition 4 is a plate shape without holes on the lower side, as long as On the upper side, it is possible to open most holes for water passage. The water chamber 3 " on the left side is connected to the secondary sewage tank 6 by the pipeline 5 ' through the filter box 5 . The lower side of this secondary sewage tank 6 passes through the last filter box 7, and the upper side is connected to a water-sealed pump 8 through a pipe 7'. The water-sealed pump 8 is a pump that circulates water with an impeller, discharges water to the outside by centrifugal force and compresses air in the center to form a vacuum. It can suction air and water at the same time. The output end of the water-sealed pump 8 is connected in the clean water tank 9 . Then, the plunger pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com