Cubic cushioning material and prodn. method thereof

A manufacturing method and technology of buffer material, applied in the field of three-dimensional buffer material, can solve the problems of shock absorption, rupture of capsule, damage of protection object, etc., and achieve the effect of maintaining the buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

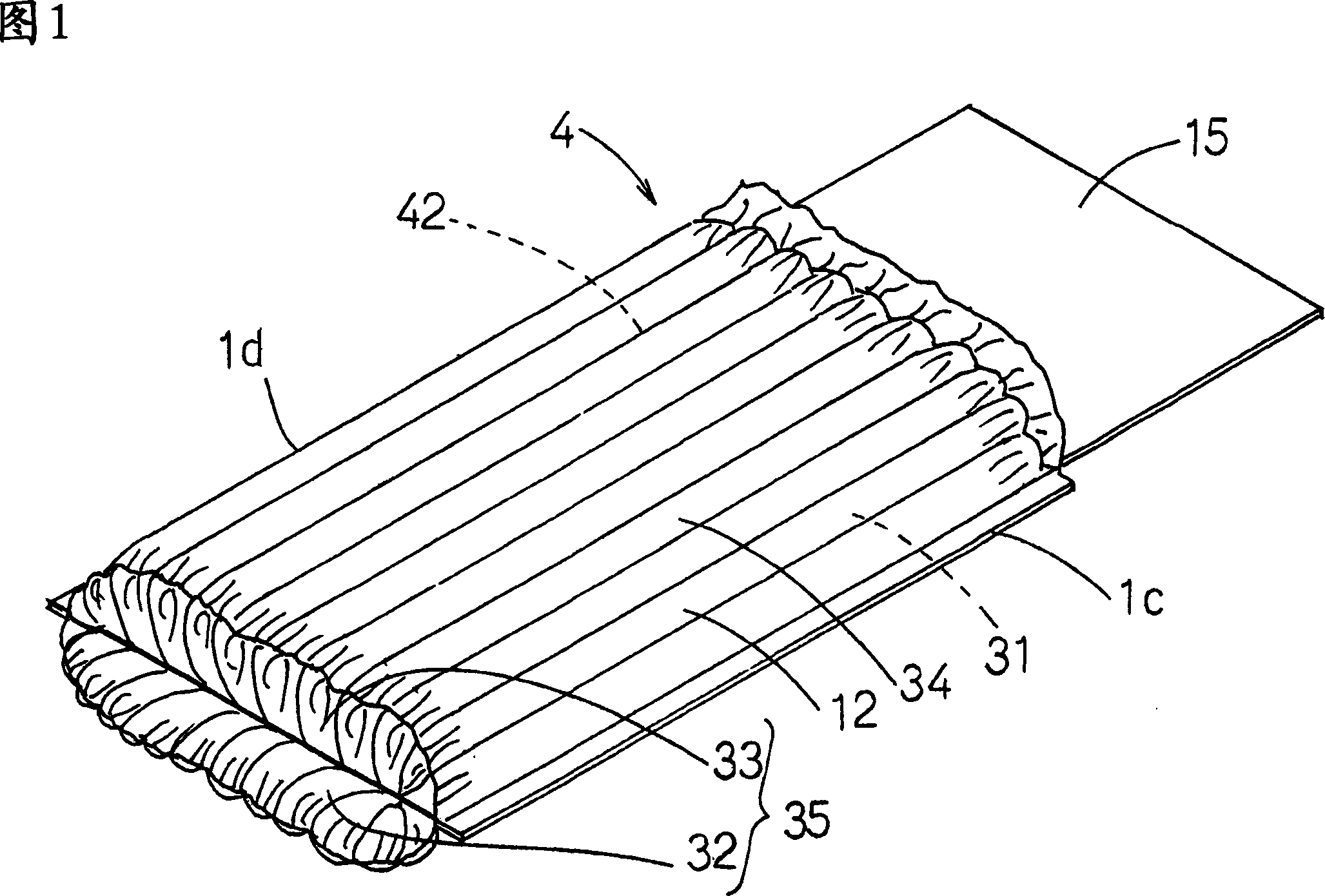

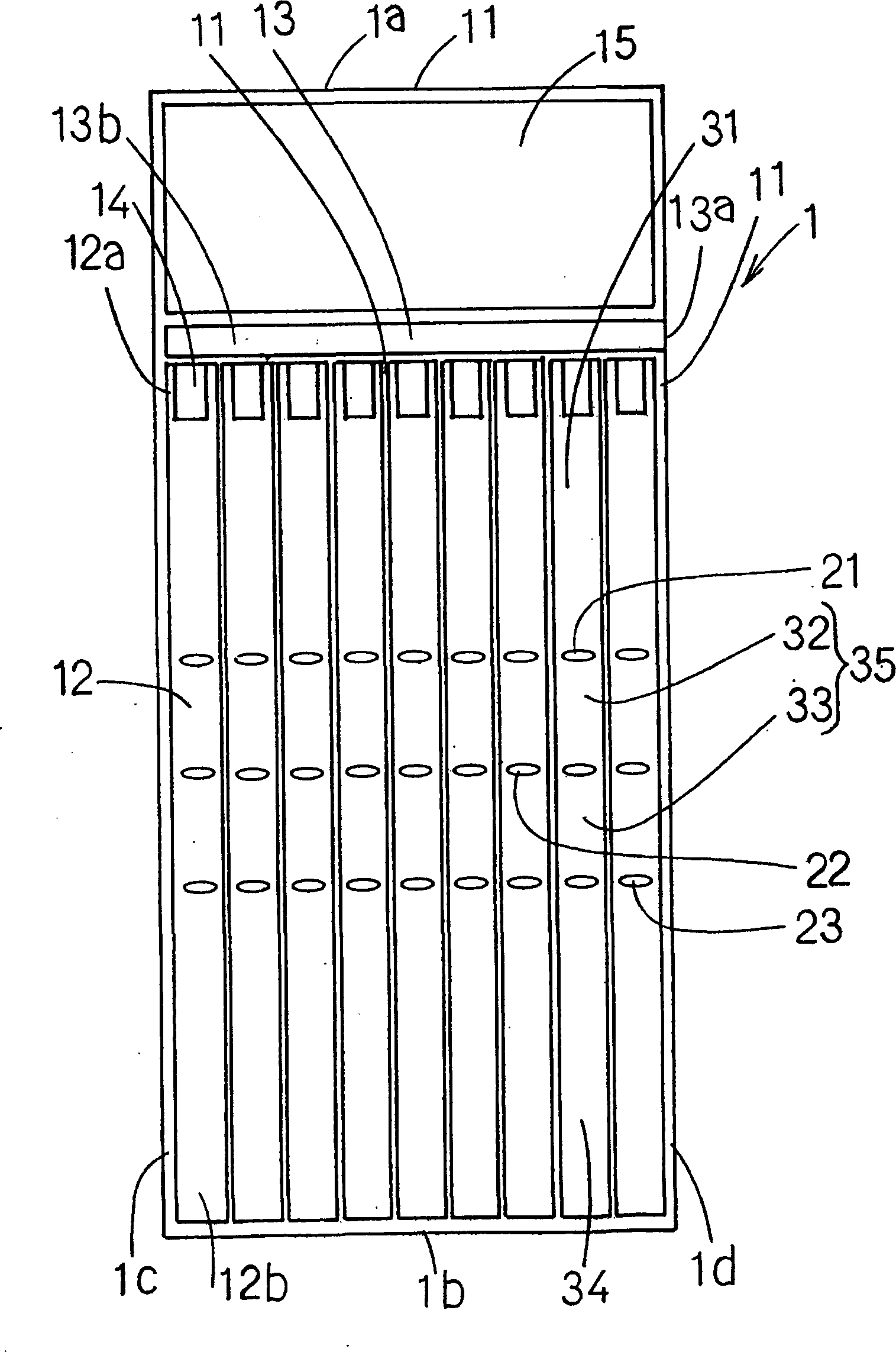

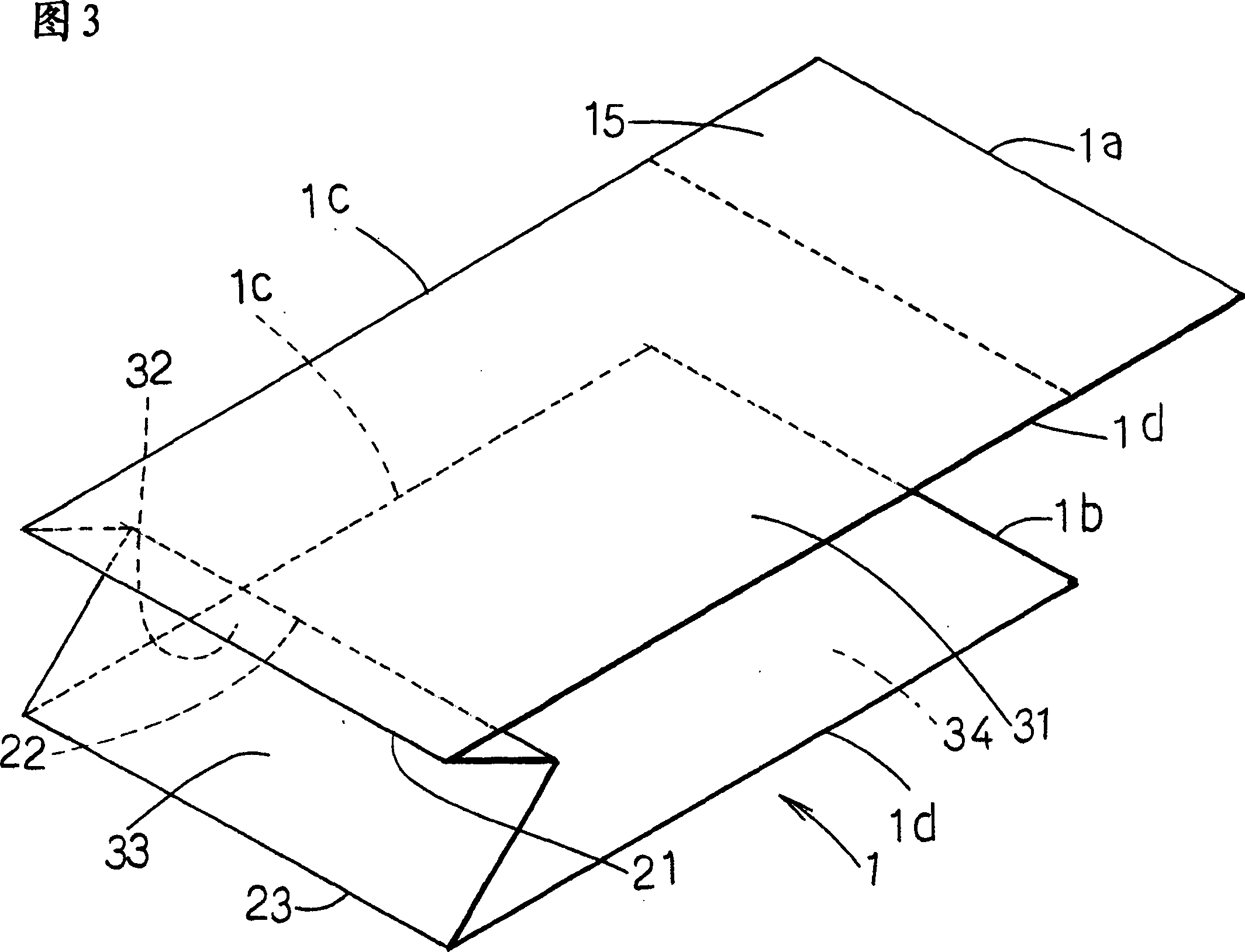

[0035] The material of the three-dimensional cushioning material 4 of the present invention adopts soft resin films such as polyethylene without air permeability, and adopts it to make the plane cushioning plate 1 at first. In this embodiment, two substantially rectangular polyethylene films having an upper short side 1a, a lower short side 1b, and a left long side 1c and a right long side 1d in a positional relationship orthogonal to each short side 1a, 1b are used. (same shape) (refer to figure 2 ). The films are laminated, and the films 11 are formed in multiple places by thermocompression bonding or the like on a part of the films, and a plurality of independent bladders 12 and air introduction passages 13 communicated with the bladders 12 are separated and formed, thereby forming such as figure 2 The plane buffer material 1 shown.

[0036] In this embodiment, two films are used to make the plane cushioning material 1 , but one film can be folded to make the same thing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com