Multiple etching technique for imitating cast copper, and its products

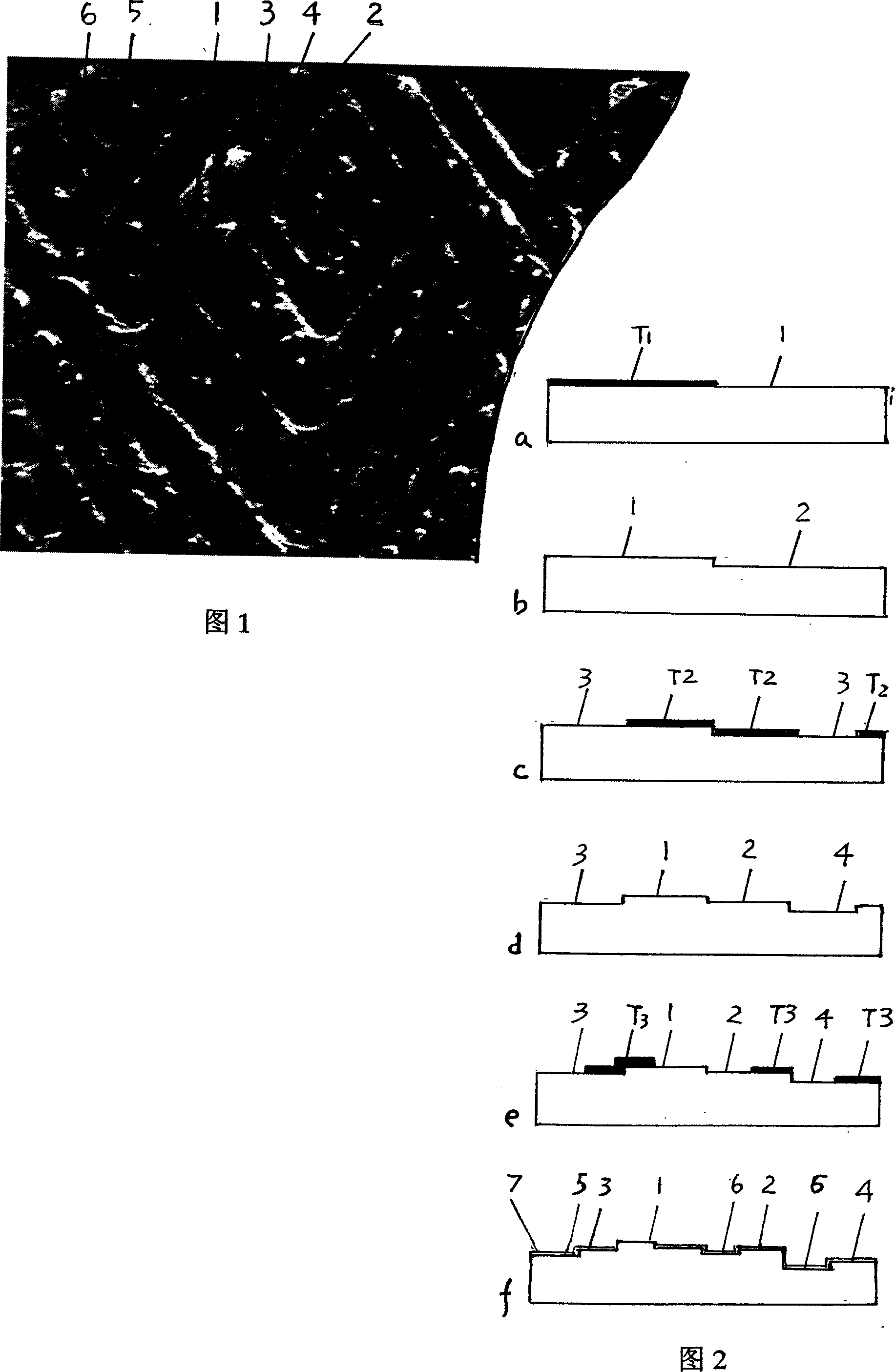

A technique of etching and casting copper, which is used in crafts and decorative arts for producing decorative surface effects to achieve realistic and three-dimensional artistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the embodiments.

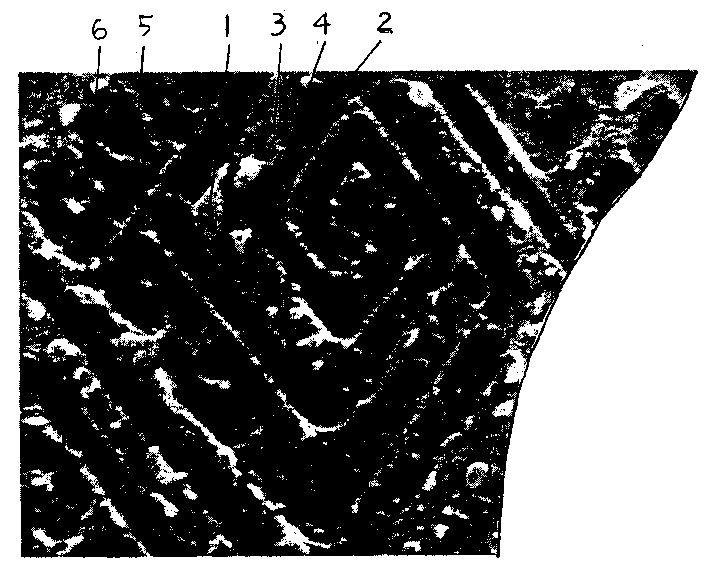

[0014] In the process embodiment, a copper plate is taken as an example. In this example, according to the protective layer diagram decomposed from the general design graphic, first coat the protective layer T1 on the base surface 1 of the copper plate (see Figure 2a), perform an etching for 20 minutes (single depth of 0.3mm), clean and form A new surface composed of surface 2 and base surface 1 is etched once (see Figure 2b). Randomly distributed protection spots T2 were locally splashed on the new surface (see Figure 2c), and the secondary etching was performed for 10 minutes (0.2mm deep each time), and four layers of different depths were formed, that is, the primary etching surface. 2 and the secondary etching surface 4 formed thereon, the base surface 1 and the etching surface 3 formed thereon (see FIG. 2d). Randomly distributed protective spots T3 were locally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com