Scandium extraction method of river channel sedimentation

A silt and river channel technology, applied in the field of extracting scandium products from river silt, can solve the problems of non-renewable mineral resources, easy damage to the ecological environment, unfavorable competition of scandium products, etc., to achieve environmental protection, improve concrete quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] Use the river silt of the Chongqing section of the Yangtze River, sample 60t, pebbles have been removed, and the maximum particle size is <2mm; 1. Select titanopyroxene concentrate from the silt

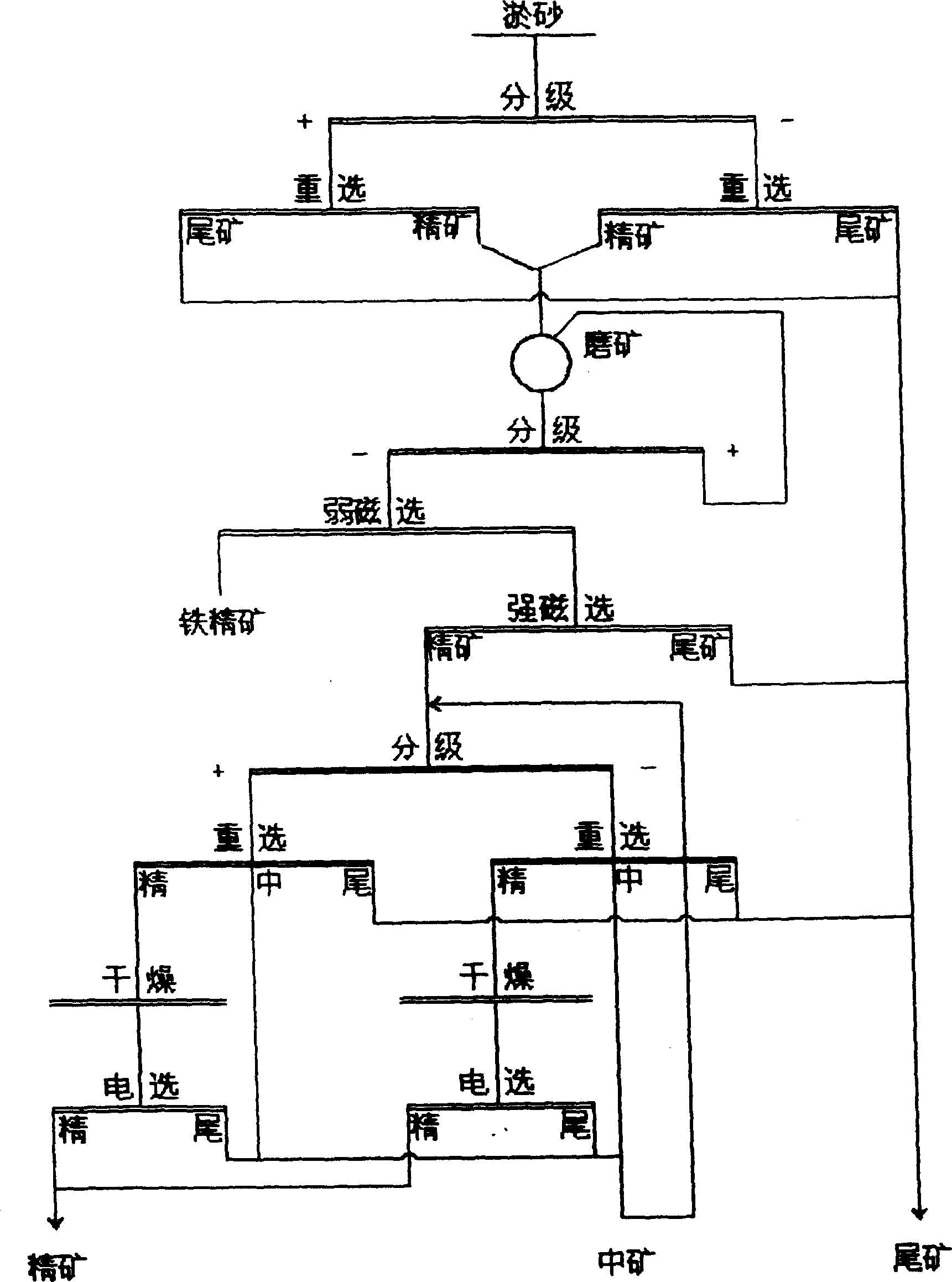

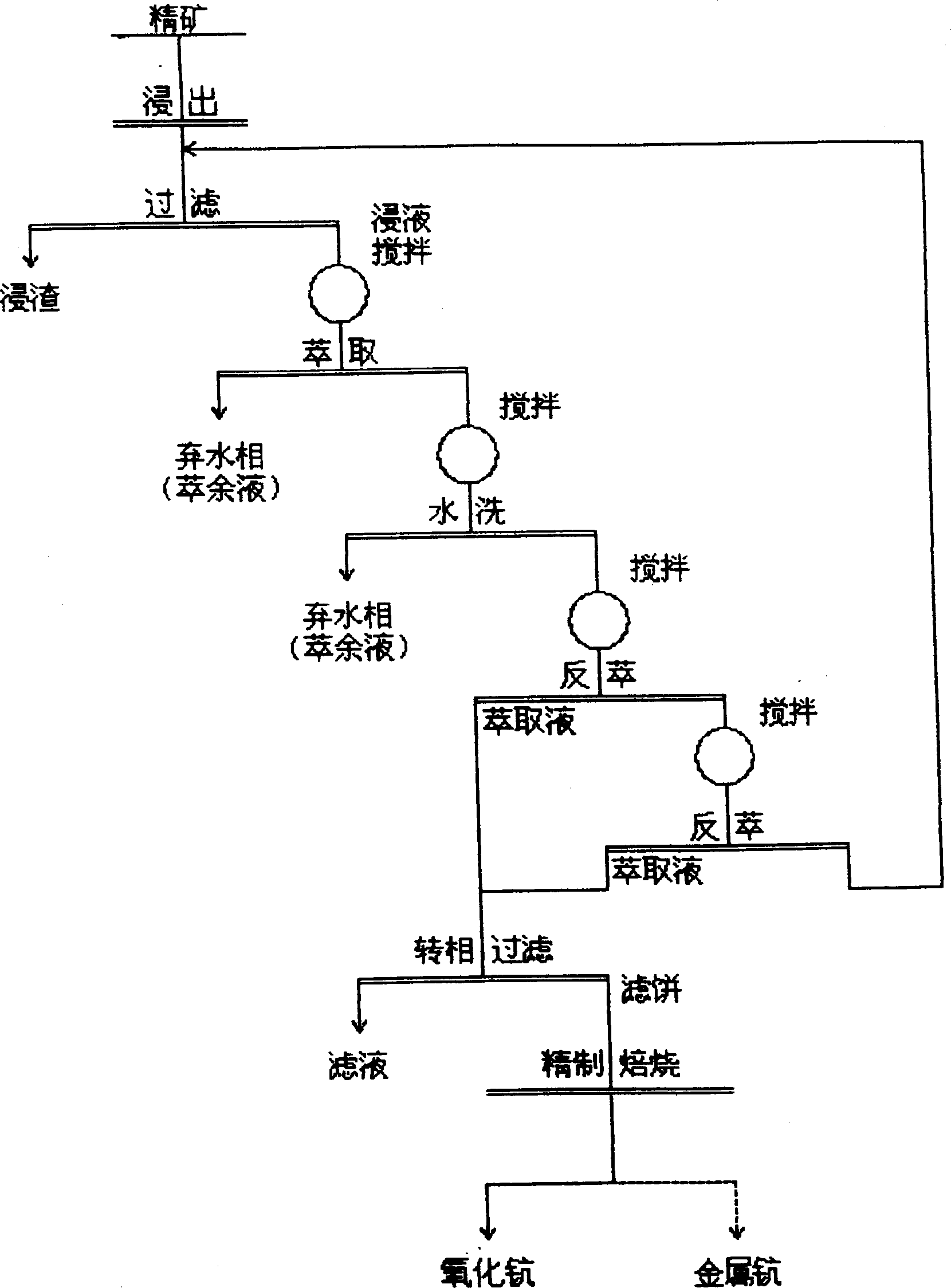

[0039] First use the sieve hole to classify the 80-mesh vibrating screen, then re-select the 80-mesh silt with the spiral concentrator and the spiral chute, and throw away 37.5% of the tailings. In order to increase scandium-containing products and ensure the dissociation of monomers, gravity-selected concentrates are combined into a closed-circuit cycle composed of ball mills and spiral classifiers. The particle size is controlled to 200 mesh and sent to weak magnetic separators. The magnetic product is iron concentrates. The non-magnetic part undergoes high-gradient magnetic separation, and 50.81% of the tailings can be thrown away. The concentrate is classified by a hydrocyclone to control the particle size to 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com