Adaptable packaging machine heat shrink tunnel

A packaging machine and heat shrinkable film technology, applied in the directions of packaging paper shrinkage, packaging, packaging paper, etc., to achieve the effect of simplifying the device, improving appearance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

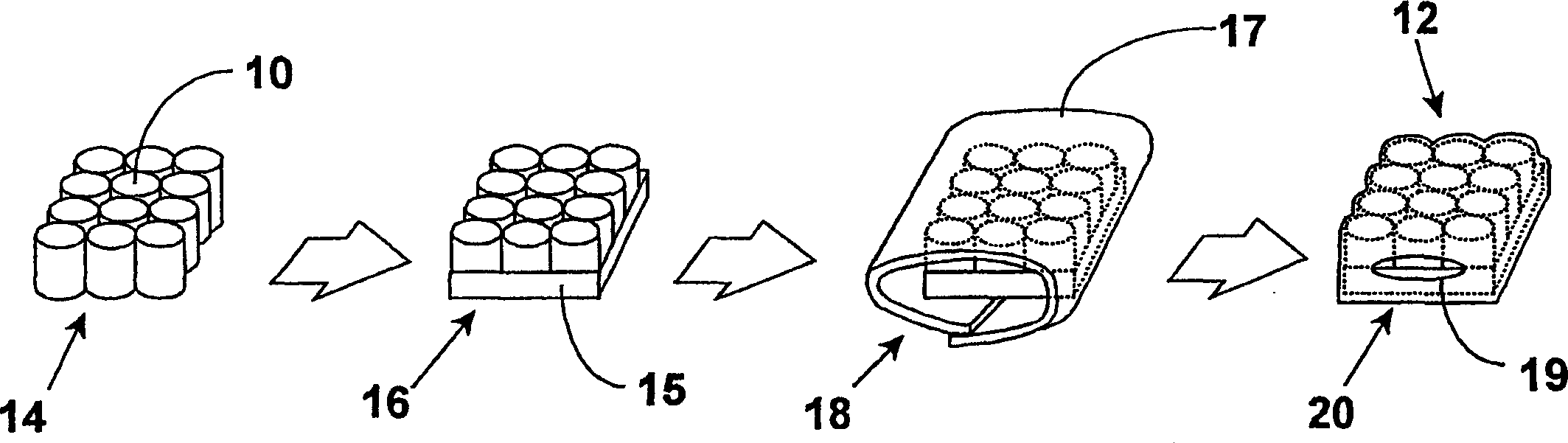

[0034] in the attached picture figure 1 Single lane packaging of cylindrical items 10 to form a finished multi-pack 12 is illustrated. The basic steps in creating a multi-pack 12 include grouping the articles 10 in a sorting section 14, forming a tray 15 around the articles 10 in a tray forming section 16, and wrapping the articles 10 in a tube formed by heat shrinkable film 17 in a film wrapping section 18. , and hot air is applied at the constricted portion 20. The tube formed by the film 17 is a heat shrinkable sheet wrapped around the article 10, lap-sealed as will be described in detail herein, and has openings at laterally opposite ends. Application of hot air to the tube of film 17 causes the opening to contract to form a small, substantially oval opening, commonly referred to as a bull's eye 19 , at the transversely opposite end of the finished multi-pack 12 . although figure 1 While the use of a tray 15 surrounding the items 10 is shown, it is expressly contemplate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com