Preparing method for acrylic acid

A technology of acrylic acid and crude acrylic acid, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of lowering the efficiency of raw materials, lowering the quality of acrylic acid, forming by-products, etc. Final yield, effect of preventing polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

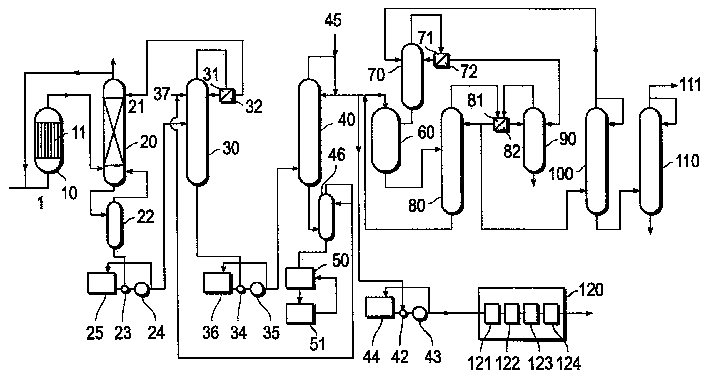

[0096] according to figure 1 Illustrated process flow for the production of acrylic acid. First, in the presence of an oxidation catalyst, the catalytic gas phase oxidation of propylene and molecular oxygen was carried out at 388 Nm 3 / Min, a mixed gas containing 7.1% by volume of acrylic acid, 0.3% by volume of acetic acid and 14.7% by volume of water was obtained.

[0097] This gas was introduced into an absorption column (cascade miniring 3P 10m) and a bottom liquid was obtained at a rate of 8050 kg / h. The absorption tower was operated at 62°C and the pressure at the top of the tower was maintained at 1100 hPa absolute. At a rate of 2720 kg / h, the water obtained by mixing the hydroquinone polymerization inhibitor, the separated water produced in the azeotropic dehydration tower, and the water containing 1.5% by weight of acrylic acid and 5.4% by weight of acetic acid produced by the vacuum generator in the distillation tower Wastewater is supplied to the top of the colum...

Embodiment 2

[0103] At the section of the azeotropic dehydration tower that provides the aqueous solution, hydroquinone dissolved in water is provided to the azeotropic dehydration tower together with the aqueous acrylic acid solution as part of the polymerization inhibitor, and is operated according to the method of Example 1. After about a week of continuous operation, the pressure loss in the azeotropic dehydration column showed signs of increasing. After about 2 months of continuous operation, the whole plant was opened and examined and it was found that polymer was deposited on the sieve tray above the section of the column supplying the aqueous acrylic acid solution.

Embodiment 3

[0105] Instead of using the overhead liquid of the maleic acid separation tower, hydroquinone was directly provided to the azeotropic dehydration tower as part of the polymerization inhibitor, and operated according to the method of Example 1. From the first day of operation, the pressure loss in the azeotropic dehydration column showed signs of increasing. After about 1 month of continuous operation, the whole set of equipment was opened and internal inspection was carried out, and polymerization inhibitor deposition occurred near the column section where the polymerization inhibitor was introduced, and the holes in the sieve plate were blocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com